Injection Blow Moulding

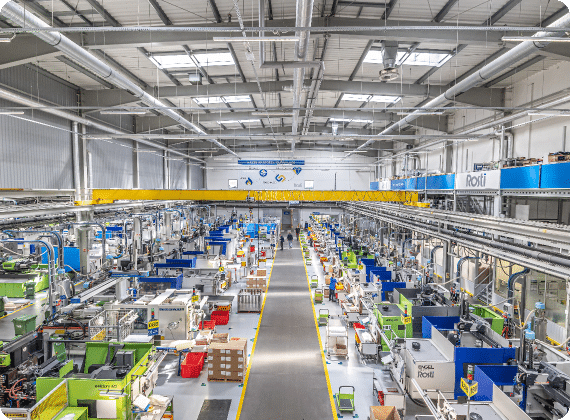

Injection blow moulding with Rosti lets you quickly improve consistency and mass-produce parts in large volumes, cost-effectively and with little waste.

We are committed to providing you with the best injection blow moulding solutions in the industry. Our expertise and experience in food and beverage production, coupled with our commitment to sustainability, make us the ideal choice for businesses seeking cost-effective and environmentally friendly product options.

Why injection blow moulding?

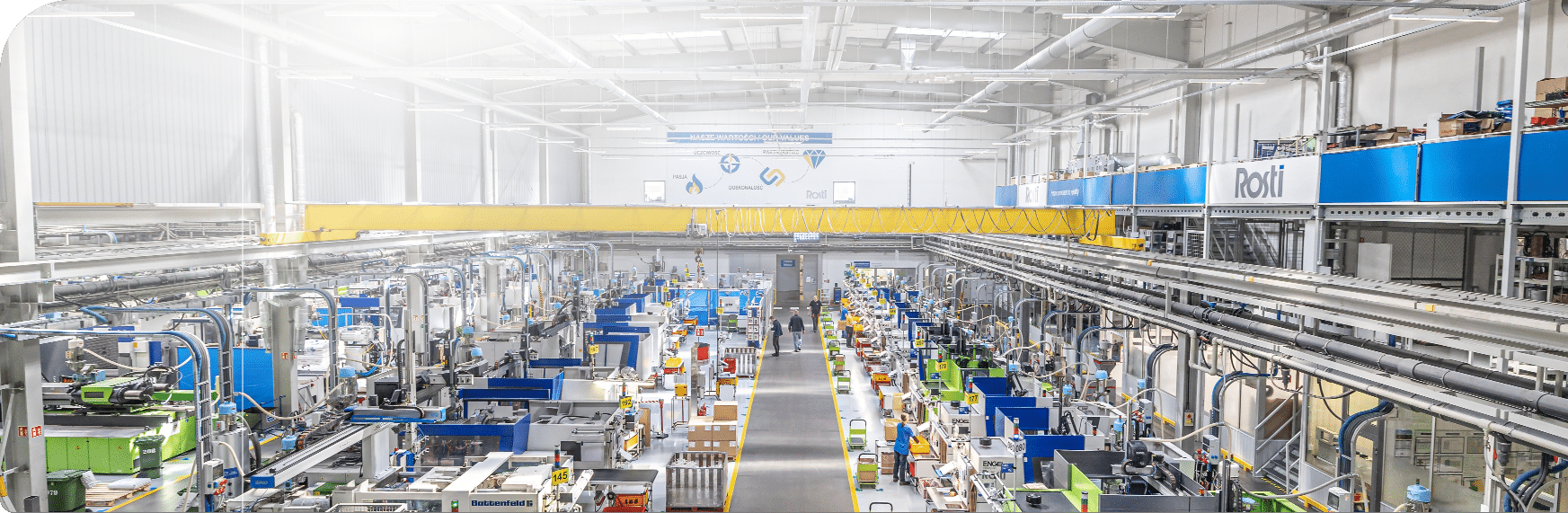

When working on any project, cost is a strong consideration. But it is especially critical when working at a large scale and in industrial applications. Injection blow moulding is a highly customizable process, making it easy to scale, based on the customer’s needs.

At Rosti, we pride ourselves on the ability to manufacture parts efficiently, with substantial cost savings and minimal waste. While injection blow moulding may not be as quick as traditional blow moulding, it offers advantages in terms of the quality of the end product. This process is particularly effective for producing thicker wall parts and transparent items, such as reusable drink cups. While the output volumes and speed may not be exceptionally high, the procedure ensures high-quality parts and can be run continuously for consistent manufacturing.

Advantages of Thicker Walls and Clear Finishes

At Rosti, our dedication to injection blow moulding allows us to deliver reliable and adaptable solutions, pushing the boundaries of its applications beyond common expectations. This commitment to quality and innovation is what truly sets us apart.

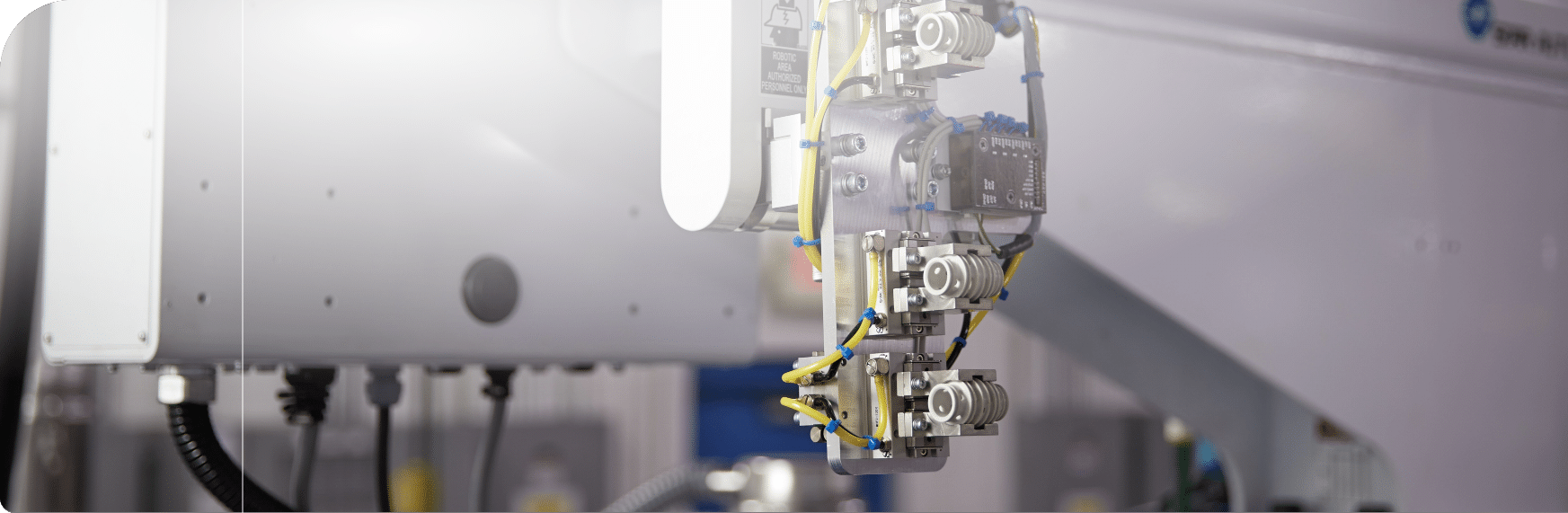

Rosti’s advances in injection blow moulding include the ability to create products with varying thickness, experience with a variety of materials and resins and more. We have developed the mass-production of glass-like, thick-walled transparent plastics for use in reusable water bottles and lighting products. Through the controlled blowing of partially hardened plastic, we can manufacture attractive products with different colour and transparency.

Our injection blow moulding capabilities are continually expanding and we help you take your projects to the next level.

Shifting Towards Sustainability: A Cup for Life

As major brands shift toward the concept of a “cup for life,” Rosti is here to support this change. A cup for life allows reusable cups to be used for an extended period of time, rather than being discarded after a single use. Rosti’s injection blow moulding expertise plays a crucial role in this transition.

A Rosti-manufactured cup for life is designed for longevity; capable of withstanding up to 1,000 washes. Each cup is equipped with an RFID tag, allowing you to keep count of the number of washes. As single-use plastics legislation is being passed across the world, initiatives such as the cup for life provide an innovative and sustainable response to meet the evolving requirements.

Rosti’s expertise in injection blow moulding provides a solution to support these initiatives, allowing companies to comply with the new regulations while also providing high-quality products for their customers.

The future demands a transition from disposable to reusable packaging and Rosti is ready to help.