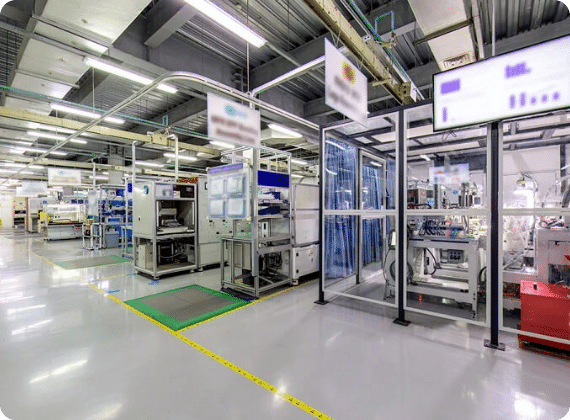

For over 40 years, Rosti North Carolina has provided creative solutions to a diverse customer base. As a full-service injection molder and contract manufacturer of precision components & assemblies, Rosti North Carolina has evolved to be a global injection molding service provider with more than 20 percent of products exported. The 51,000 square foot facility hosts 27 injection molding presses ranging from 55 to 1,200 tons.

Rosti North Carolina | 100 Falcone Parkway | Cary, Nc 27511

Rosti US Terms and Conditions

Facts & Figures

51,000ft² Facility

50+ Employees

Established 1980

Certifications

Take a look at our industry specific certifications from approved bodies, to ensure we provide you with guaranteed service.

International Standard for Quality Management (2015 - latest version)

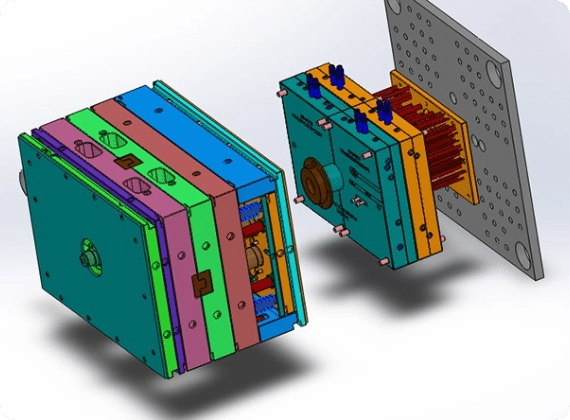

Our Capabilities

Rosti North Carolina expert engineers and technicians help customers realize efficiencies through an extensive design for manufacturing (DFM) process, custom tool building services, and advanced injection moulding processes. Through comprehensive DFM analysis, mold design analysis (DRAFTSIGHT), the integration of SolidWorks predictive fill simulation software, and injection molding capabilities up to 1,200 tons, the North Carolina facility also specializes in full-service assembly, heat staking hot stamping, interesting, machining, riveting, solvent bonding, and more.

Our services

In conjunction with all Rosti facilities, the North Carolina team adopts and customizes the latest technology and production resources on a continual basis for improvement in all facets of the business. Metrics have shown increasing efficiencies in these areas result in lower costs for customers and the greater go-to-market flexibility and responsiveness required in today’s dynamic global market.

Offering design support, material selection, prototype development, and a multitude of value-added services, the Southeast facility serves a wide range of industries, including plumbing, appliance, filtration, automotive, engine, medical, food and electronics, to name just a few.

Get in touch

Address

Rosti North Carolina | 100 Falcone Parkway | Cary, Nc 27511