Injection molding technology has evolved greatly since the Hyatt brothers patented the first injection molding machine in 1872. Their initial plunger design was improved upon in 1946 when James Hendry created the first auger injection molding machine. But it wasn’t until the computer age when advances to the injection molding process started to take shape. Today’s plastic injection molders must stay at the forefront with scientific molding principles and processes to meet the demands of quality, consistency, efficiency, production, and cost savings.

Tag: Additive Manufacturing

Design Tips for Injection Molding with High-Heat or Exotic Resins

Throughout the injection molding process, there are several factors that affect efficiencies and viability of a plastic part. Before production begins, there are important design elements to consider – particularly when a part requires the use of a high heat or exotic resins.

Rosti provides Integrated design solutions for a major launch into the market of a Smart Beauty Device System

We are delighted to announce the launch of a Smart Beauty Device System for a global leading brand in the health and beauty market, providing innovative integrated design solutions and contract manufacturing capabilities.

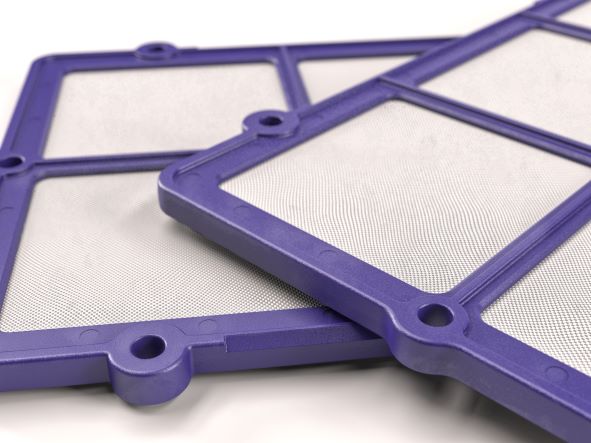

Why choose injection moulding for your Air and Water filtration products?

The modern filter has become a vital element in ensuring optimum performance of appliances and devices across both air and fluid management industries.

Inside Rosti – Happy Holidays

In the 2nd issue of Inside Rosti, Jonas Persson, Rosti Group CEO, reflects on the past 12 months for our global business, discussing how we have grown and evolved to support our customers plastic injection moulding needs. He also touches on his outlook 2024 for both the global economy, the world of plastic injection moulding and Rosti Group’s strategy.