At Rosti, we go beyond plastic injection moulding with our comprehensive range of Surface Finishing options. Our in-house expertise will not only enhance the quality of your products but also help to streamline manufacturing processes, reduce costs and accelerate speed-to-market.

Tag: Injection Blow Moulding

Key Qualities of High-Heat and Exotic Resins

Resin materials used in plastic injection molding have evolved significantly in recent years as advancements to combining plastics with fillers and reinforcement materials has become more common in many industrial applications to improve part performance and strength. In the past, plastics were not known to be highly heat resistant materials. It is becoming more known that there are now many high performance resins that can be put to use at temperatures up to 572 degrees Fahrenheit – depending on the part / product’s environmental factors and exposure to chemicals. High heat and exotic resins are particularly good metal replacement options because they provide incredible benefits in the areas of weight savings, chemical resistance, and sliding friction characteristics. Additionally, these great attributes can be maintained at high permanent operating temperatures.

Design Tips for Injection Molding with High-Heat or Exotic Resins

Throughout the injection molding process, there are several factors that affect efficiencies and viability of a plastic part. Before production begins, there are important design elements to consider – particularly when a part requires the use of a high heat or exotic resins.

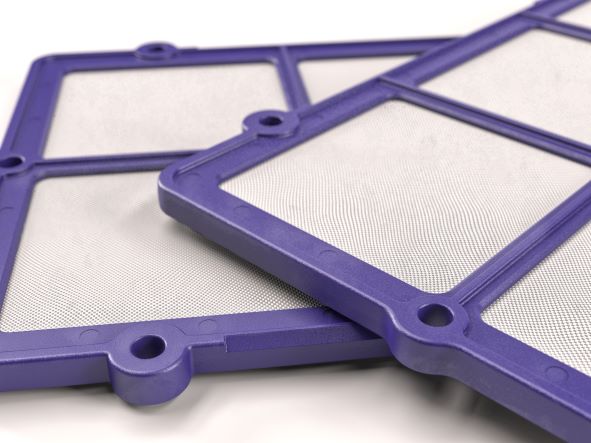

Why choose injection moulding for your Air and Water filtration products?

The modern filter has become a vital element in ensuring optimum performance of appliances and devices across both air and fluid management industries.