Tag: Rosti Wisconsin

Rosti North America Expands Medical Manufacturing Capabilities with New ISO Class 8 Cleanrooms in Wisconsin and Utah

New cleanroom investments strengthen Rosti’s support for regulated medical and life sciences customers and position the company for continued growth.

Looking Ahead to 2026: Driving Global Growth, Innovation and Sustainability at Rosti Group

As we step into 2026, Rosti Group enters the year with strong momentum and a clear vision: to deliver long-term value for our customers through strategic investments, cutting-edge injection moulding technology, and technical excellence across a truly global network.

Rosti North America Opens Digital Innovation Lab to Support Global Injection Moulding Services

Rosti North America’s new Digital Innovation Lab in North America is helping to revolutionise rapid prototyping with its accelerated concept-to-reality process in just 72 hours. Rosti North America announced today the grand opening of its state-of-the-art Digital Innovation Lab in North America, located in the company’s Germantown, WI manufacturing facility on Bunsen Drive.

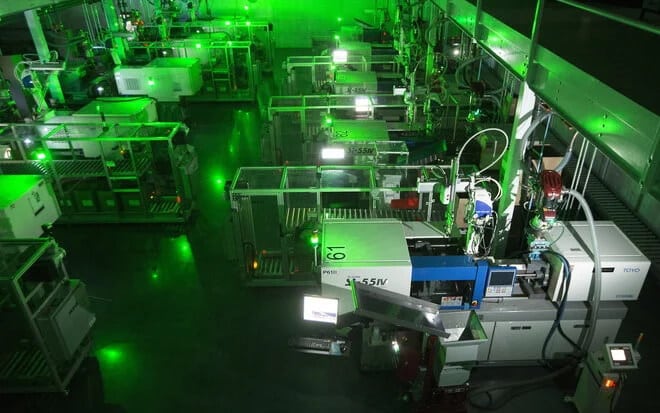

5 Ways Lights-Out Manufacturing Has Transformed Injection Moulding

The tendency for North American manufacturers of plastic parts to outsource tasks to South America or overseas is changing back toward reshoring – or that of keeping production processes in house and within the United States. After decades of offshoring for economic purposes, wages in emerging economies have started to rise substantially.

How RJG eDart Transformed PCI’s Injection Moulding Operation

Injection molding technology has evolved greatly since the Hyatt brothers patented the first injection molding machine in 1872. Their initial plunger design was improved upon in 1946 when James Hendry created the first auger injection molding machine. But it wasn’t until the computer age when advances to the injection molding process started to take shape. Today’s plastic injection molders must stay at the forefront with scientific molding principles and processes to meet the demands of quality, consistency, efficiency, production, and cost savings.

Plastic Components, Inc. Purchases Additional Facility -Video Sneak Peak!

As part of Plastic Components, Inc.’s fully automated production strategy, the company recently invested in the purchase of a new 15,000 square foot facility located on Bunsen Drive in Germantown, WI to support the company’s growth from its existing customer base and new market opportunities. The company investment included the purchase of a new building, remodeling and new equipment; which will allow PCI to remain efficient and globally competitive.

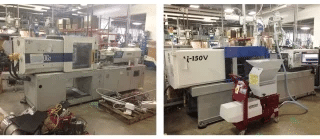

PCI Purchases New 300 Ton Press

In order to meet the growing demands of its customers, Plastic Components recently purchased a new 300 ton Toyo electric press for the Morse Drive location. PCI currently owns three-300 ton presses, but due to increased orders and new business, the need for additional capacity was apparent.

Press 18: Out with the old, and in with the new!

InJune of 2014, we retired one of our longest standing and operating injection molding presses. Press 18 had produced over 100,000,000 components during her tenure and was one of the most reliable machines in our facility. However, after over a decade of service, it was time to invest in a replacement.

A New 400 Ton Press Has ArrivedI

Plastic Components, Inc. is proud to announce the arrival and implementation of a new 400 Ton Toyo Injection Molding machine. This is the second 400 Ton press within the facility. A is the standard at Plastic Components, the press will be part of a fully automated manufacturing cell. This is the fundamental premise behind the manufacturing strategy at PCI. Using state of the art robotics and conveyors, we are able to sell components to our customers with no direct labor. This allows PCI to produce defect free parts at globally competitive pricing.