Discover Turnkey Contract Manufacturing

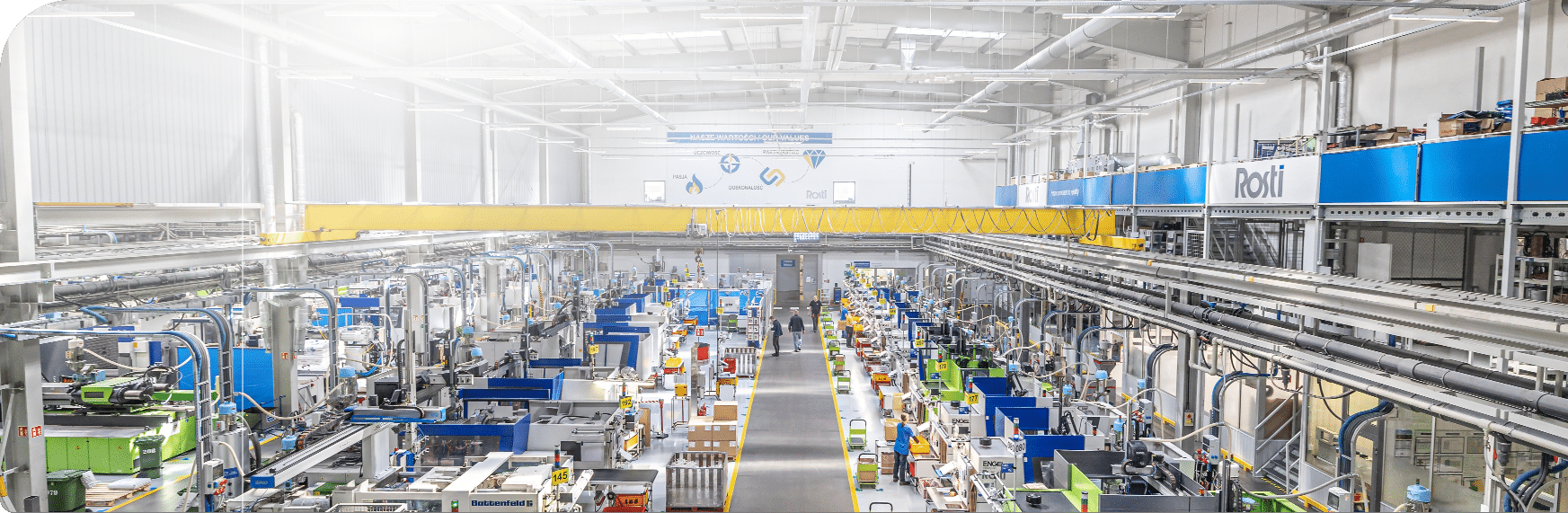

At Rosti, we take pride in being big enough to deliver and small enough to care – and nowhere is that more evident than in our custom turnkey manufacturing solutions. We provide contract manufacturing solutions across multiple markets, offering a complete end-to-end solution. With the scale and resources to manage large, complex projects, combined with the flexibility and personal attention that define our approach, we ensure every partnership runs efficiently and delivers exceptional quality.

From concept to reality

With decades of experience and innovation, Rosti provides leading edge technology for injection moulding projects worldwide – but we also deliver our customers a far wider range of services. We provide managed and contract manufacturing services, from initial product concept and design all the way through to logistics and delivery. With our range and depth of capabilities we can help you through any and all stages of manufacturing. Contact us to learn how we can help you with your contract manufacturing needs.

As a company, we have carefully managed our expansion over the past 20 years, to make sure that we retain our flexibility and accessibility in contract manufacturing. The result is that we proudly deliver projects both to small businesses and to some of the biggest companies in the world.

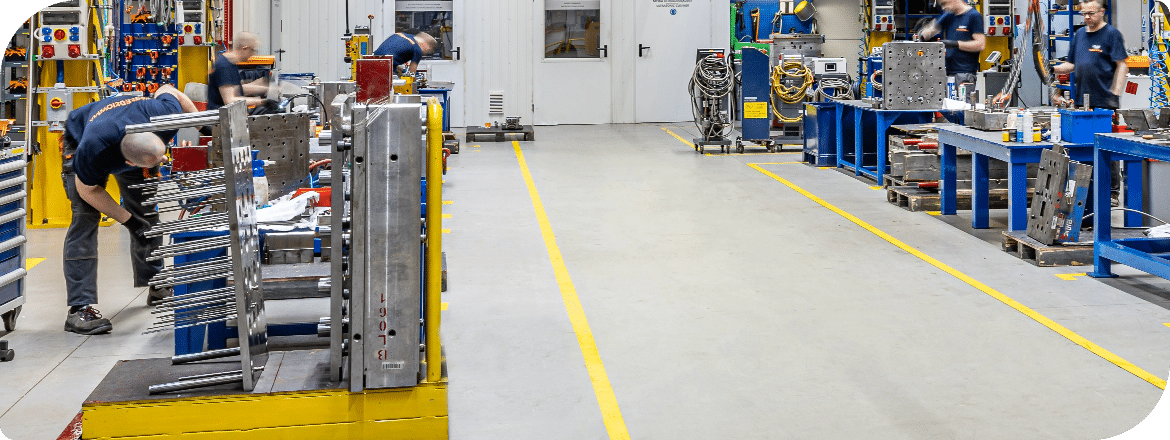

Precision Production Tailored to Your Needs

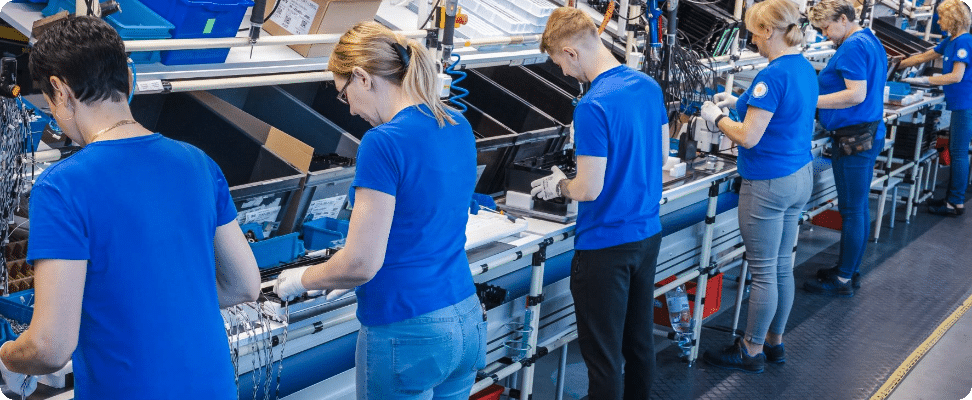

We bring extensive experience across a variety of production volumes, allowing us to deliver unmatched flexibility and efficiency. Whether it’s a small prototype or a high-volume production run, we maintain the highest standards of manufacturing accuracy. Contract manufacturing for us means delivering the right product for the right application – using the right materials and optimal production conditions. With our diverse range of production techniques and material options, we ensure every product meets its exact specifications and quality expectations.

Sustainable Contract Manufacturing for the Plastic Injection Market

We see product design as a partnership between customer and manufacturer, and our goal is to ensure that the final product is not only compliant with all regulations, but also optimised for manufacturability.

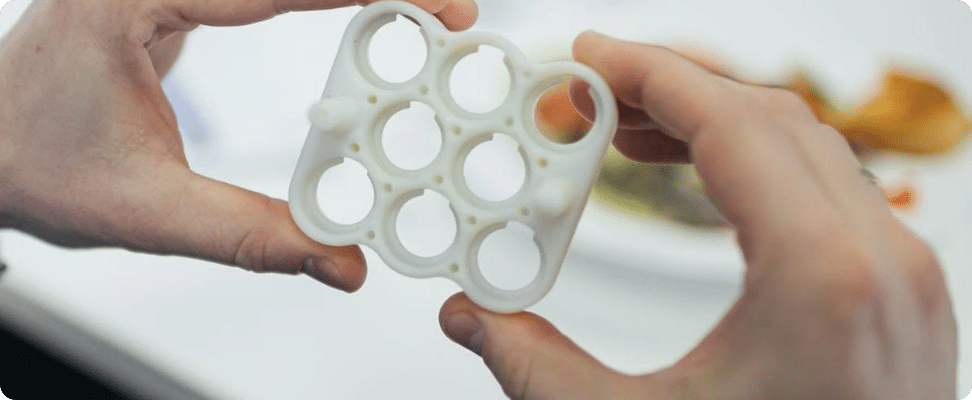

Rapid 3D prototyping has revolutionised the contract manufacturing process by allowing companies to rapidly iterate on design concepts and produce parts quickly and efficiently. Rapid 3D Prototyping is an essential tool for any company that is looking to improve their product development process.

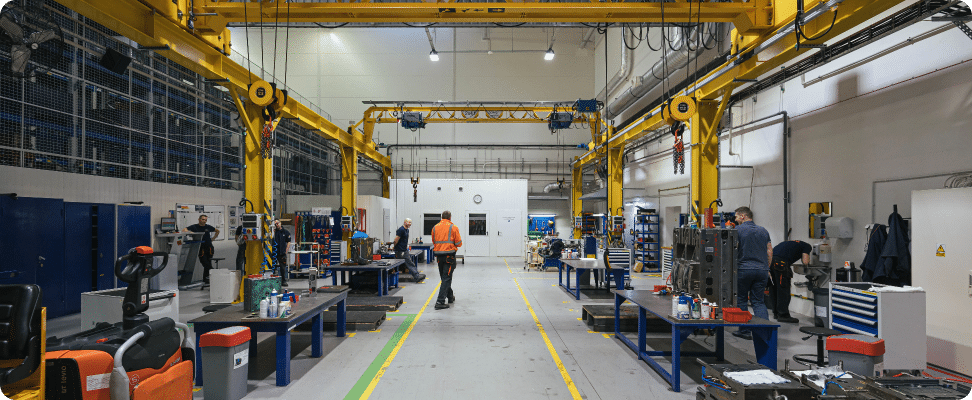

Tooling management includes everything from design and development to maintenance and repair. An effective tooling management system can also help to reduce costs by reducing the need for rework or scrap. As a result, tooling management is an essential part of any contract manufacturing operation.

With a network of suppliers covering 27 countries and dedicated quality assurance teams, Rosti provides a streamlined, flexible supply chain that ultimately reduces your production costs and lead times. We partner with you through every aspect of the process.

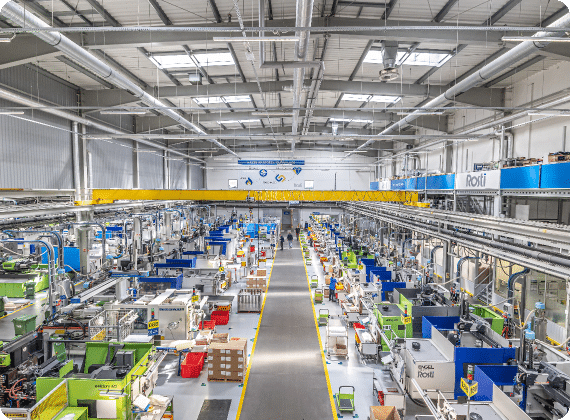

With decades of industry experience and state-of-the-art moulding machines, we have the knowledge, skills, and tools to take on virtually any plastic injection moulding project.

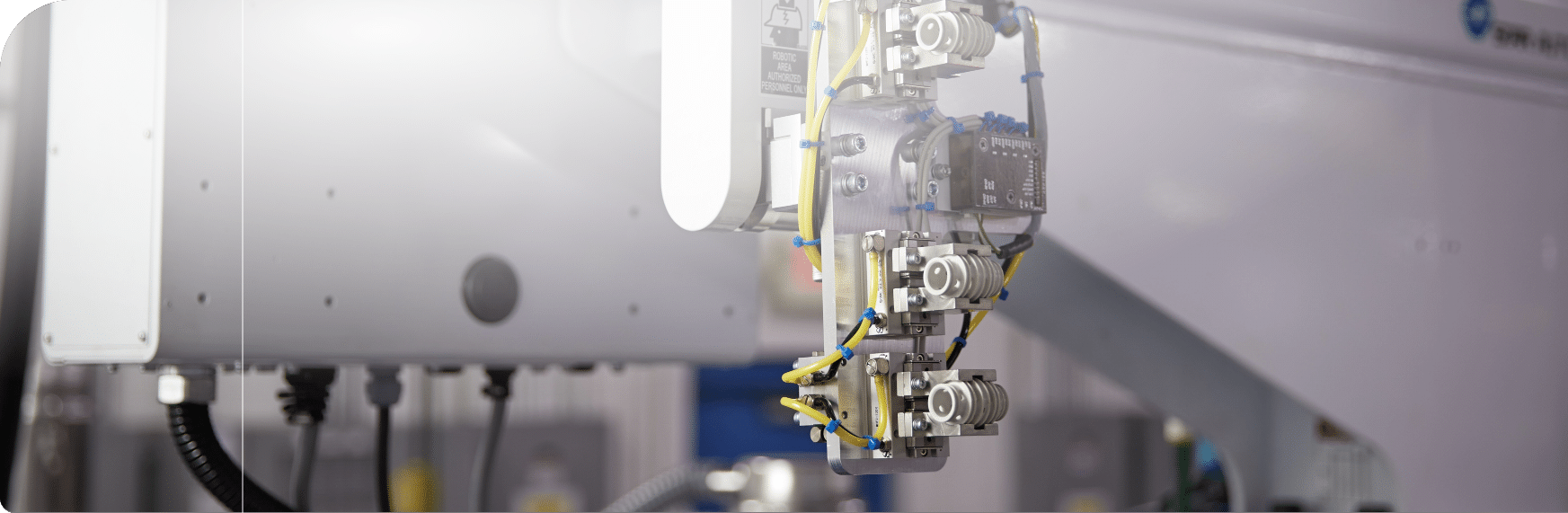

Through years of research and development, we have perfected methods that are effective, reliable and economical and open up new possibilities for improved product design, recyclability, strength, and range of materials. And because of our sophisticated automation technology, we can do it in a way that’s extremely efficient and economical.

You will find flexibility, reliability and

unparalleled experience from a dedicated team at Rosti.

Global and Custom Turnkey Manufacturing Solutions

We are a proactive partner to our customers. We develop and maintain close relationships, and we aim to be a crucial part of your success. To stay close to our customers, we have sites across the world, including innovation centres in the UK, Eastern Europe and Asia, and a packaging product solutions team located in Germany.

For maximum value, it is best to involve Rosti as early in your product development process as possible – ideally during the design stage. That way, we can anticipate the challenges and opportunities that lie ahead and help you to make efficient, sustainable decisions about material selection and product functionality, as well as manufacturing, assembly, decoration and logistics.

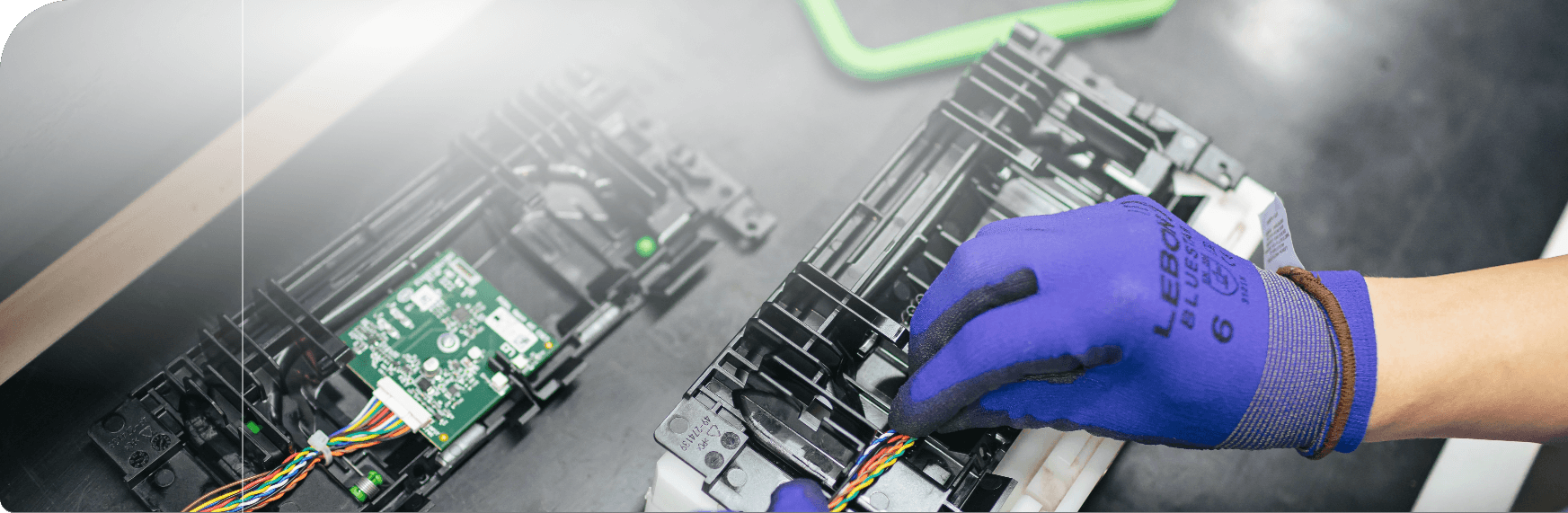

Rosti made with care and precision

Having successfully contract manufactured millions of products, everything we produce is made with care and precision, and our commitment to continuous improvement and innovation means that you can access the most advanced technologies our industry has to offer. Contact us today to see how we can help with your contract manufacturing needs.

Frequently Asked Questions

Contract manufacturing happens when one company partners with a specialized manufacturer to produce specific components or products for a set period of time. Think of it as outsourcing production to experts who can deliver exactly what you need, when you need it.

In a typical arrangement, a contract manufacturer produces parts, components, or even complete products according to the client’s specifications. These items are then used by the client in their own manufacturing process or incorporated into their final products. Many contract manufacturers operate as third-party specialists, either focusing solely on subcontracting or supplying products to multiple companies.

Learn more about contract manufacturing.

From an early stage in our contract manufacturing process, sustainability is a core element of conversations with our design and innovation teams to ensure that we are able identify opportunities to help you reduce your impact on the environment.

We are continuously investing to ensure all aspect of our business operations are reducing Rosti’s impact on the environment and this can be seen throughout all aspects of our contract manufacturing services.

From providing options to manufacture in sustainable and recyclable materials during the design phase through to energy-efficient machines. Adopting automated and lights-out production enables us to move away from traditional manufacturing methods, helping to drive efficiencies when it comes to material utilisation and reducing waste.

When planning the logistics and delivery of a finished product, packaging is an integral part to to transporting high-quality products. Our Contract Manufacturing team support customer to select light-weight returnable or recyclable packaging to reduce waste and emissions whilst maintain quality standards.

Rosti operates 12 state-of-the-art production facilities strategically located across Europe, North America, and Asia. This global footprint allows us to manufacture close to your end markets, helping to reduce lead times, optimise supply chains, and support your sustainability goals. By accessing the full breadth of our plastic injection moulding capabilities at any of our sites, you benefit from consistent quality, efficiency, and innovation worldwide.

The advantages of this approach include reduced time to market, the ability to navigate economic headwinds with greater flexibility, and opportunities to lower costs through optimised production and logistics – helping you stay competitive in a fast-changing marketplace.

Yes. At Rosti Group, our support goes far beyond plastic injection moulding. Our Plastic Contract Manufacturing services provide full design and engineering services, helping customers bring ideas from concept through to production.

Our teams collaborate with you at every stage of the product lifecycle — from initial design for manufacture (DFM), prototyping within 72 hours, and material selection, through to tooling, testing, and full-scale production. By combining advanced simulation, rapid prototyping, and in-house engineering expertise, we ensure your products are optimised for performance, cost efficiency, and sustainability.

This end-to-end approach not only accelerates time to market but also reduces risks, waste, and costs throughout the supply chain.

Quality and compliance are central to everything we do at Rosti Group. All of our 12 manufacturing facilities operate under internationally recognised certifications, including ISO 9001, ISO 13485 (medical), ISO 14001, and ISO 50001, ensuring rigorous standards for quality, sustainability, and energy management.

Our teams follow robust quality assurance processes, including advanced product validation, in-line inspections, and traceability systems to guarantee consistency and reliability across every production run. For highly regulated sectors such as medical devices, automotive, and consumer goods, we ensure strict adherence to industry-specific standards and regulatory requirements.

Through continuous improvement programmes, data-driven monitoring, and close collaboration with our customers, we deliver products that not only meet but often exceed expectations for quality, safety, and compliance.

OEMs and contract manufacturers differ primarily in terms of control, intellectual property ownership, and design responsibility. An Original Equipment Manufacturer (OEM) produces products according to a client’s precise design, with the client retaining ownership of the brand and intellectual property. In contrast, a Contract Manufacturer (CM) typically manufactures parts or complete products based on the client’s specifications, while the client maintains control over the design and production requirements. In many cases, contract manufacturing forms part of an OEM relationship, where the CM serves as the production partner or factory, and the client acts as the OEM.

Get in touch

We are only a message away.

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.