Product Design

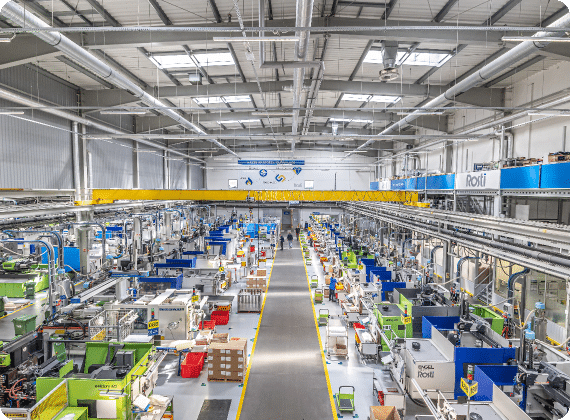

Looking for innovative and sustainable product design? Our end-to-end injection moulding services deliver just that.

The guidance we provide during the design process emphasises innovation, performance and sustainability. We always try to find ways to embed these values in the entire project. The result is a product design that is perfectly aligned with the production process, for streamlined manufacturing and less waste.

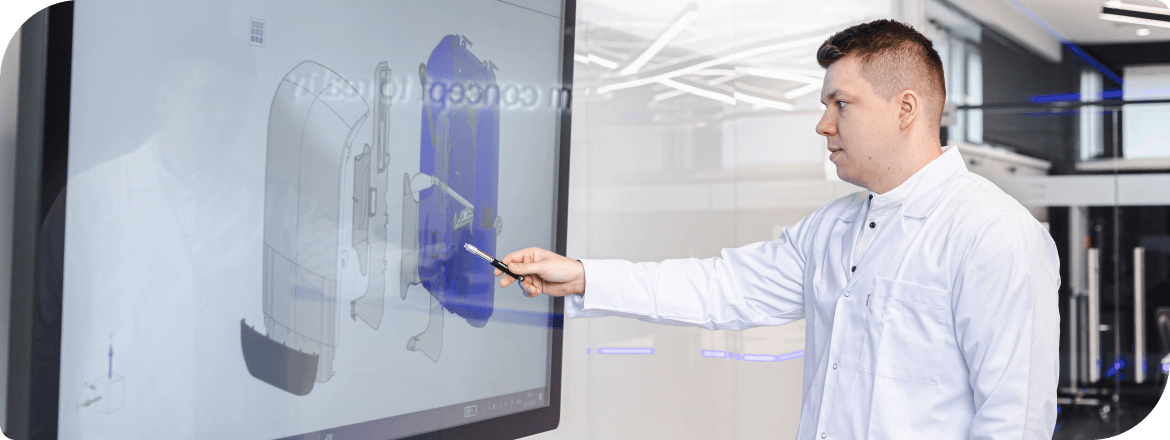

At Rosti, product design is one of our specialities. From product conception to prototyping and manufacturing product design, we have the experience and capabilities to help you bring your product vision to life. Our expert product designers and engineers can work closely with you throughout each step in the product design process to ensure that everything exceeds expectations. We understand that product design can be difficult and confusing, so we make sure to guide you every step of the way. That’s why product design with Rosti is so successful – our experience and expertise means product designs become a reality with minimal stress.

Saving you money, materials and time

With decades of experience in injection moulding, we can see the opportunities and risks in every project from a very early stage. By partnering with Rosti at the beginning of your project, you not only get product design support from skilled engineers and product designers, but you also get insight from a supply and manufacturing perspective. Working with Rosti on your product design helps to streamline production, reduce waste, and ultimately save time and money.

With our product designers’ scope of expertise, we can deliver total solutions – from concept to reality – while letting you decide how much day-to-day involvement you want to have. You can even consult us after the design phase has begun. We are happy to meet with you and your product designer to discuss the feasibility of your project, and identify the performance and sustainability issues that are likely to affect it. Together we will design solutions that work to create a final product everyone is happy with.

We have a skilled and highly competent team of product designers and engineers, who are capable of both developing innovative ideas and optimising your product design.

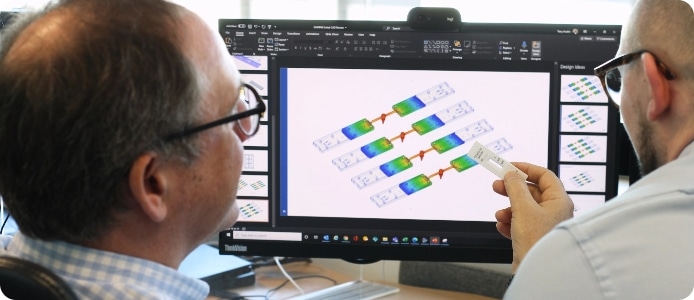

They are supported by customised software solutions that bring your ideas to life. A couple examples are below:

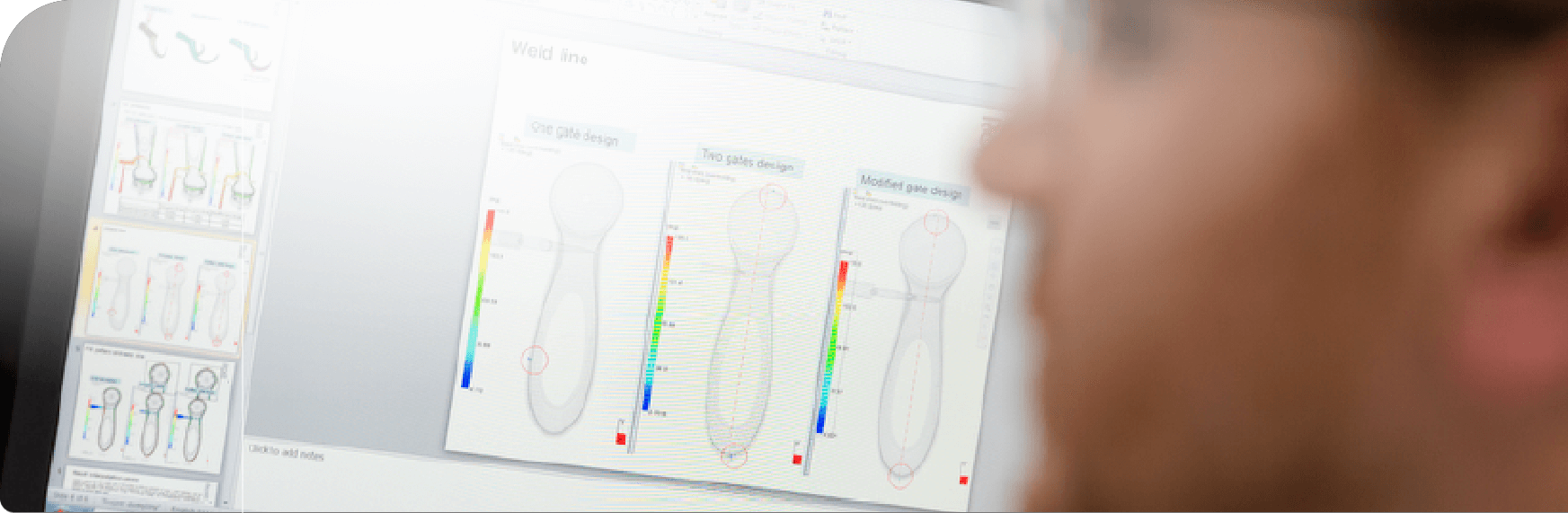

- Rosti Expert Analytical Systems is a suite of tools for component design and tool optimisation.

- A customised version of Autodesk Moldflow Insight and Moldex to simulate production and troubleshoot problems before manufacturing kicks off.

The goals of this approach are to streamline project management, reduce costs and avoid the risks you might otherwise encounter when working with new materials, tools and processes.

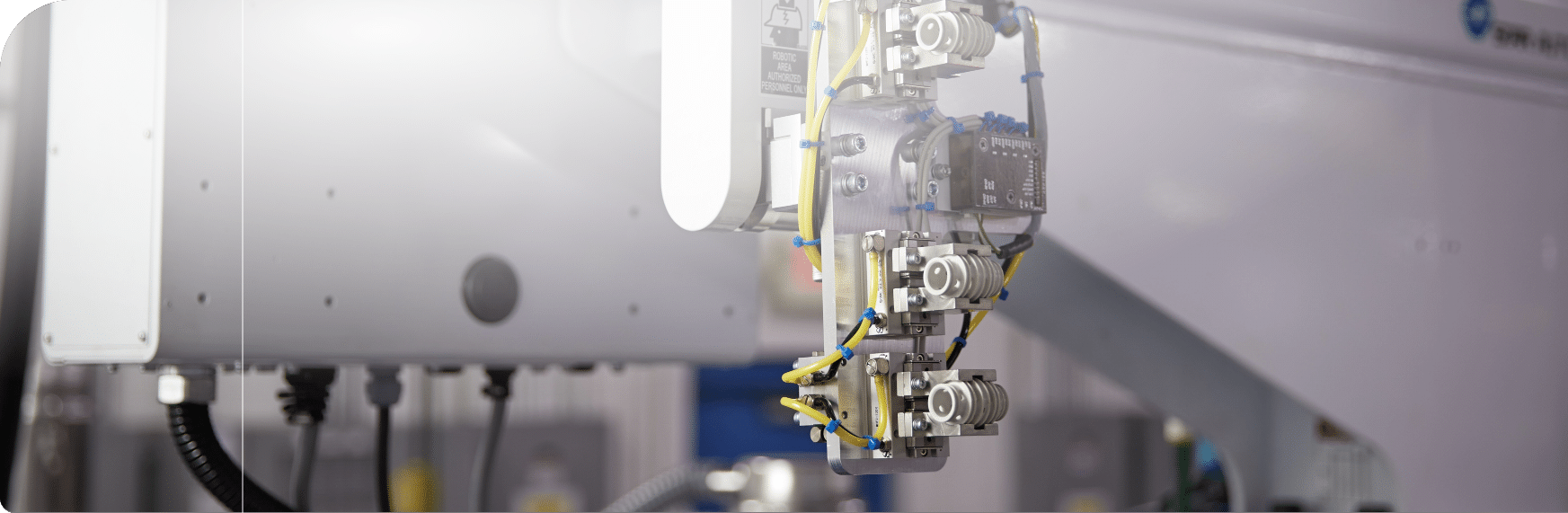

As total solution providers we understand the value of quick, accurate prototyping, so we have two different approaches that we apply according to the demands of your project.

We often work with a select group of specialised suppliers to provide a quick and cost-effective service in prototyping. We have also developed our own direct digital manufacturing (DDM) procedures, that allows us to create prototypes using 3D printing, removing the need for investment in traditional tooling. We work with different prototype materials and methods to provide you with prototyping tools that are appropriate to your project’s needs.

We have a skilled and highly competent team of product designers and engineers, who are capable of both developing innovative ideas and optimising your product design.

What are the phases of product design?

Product design usually takes months or even years, depending on the nature of the final product. All stages of design and product design are crucial to their success.

Not all product design concepts are shared outside of the office. At Rosti, we have an internal screening process to spot any non-viable ideas. While assessing design ideas, we will consider the design’s price, revenue, competition, longevity, etc.

This phase is where the real product development begins. First, a prototype is built and then the prototype is tested. If the design is successful, it can be manufactured and continue to move through the step by step process.

After testing products, the final stages are conceptualizing and evaluating the products. If everything has gone to plan, the product is ready to rollout to the end user.

How to make a product that is both

functional and aesthetically pleasing

Crafting a product that is both functional and aesthetically pleasing requires a great deal of thoughtful product design. Forward design thinking will ensure that every product is designed in a way that pulls together the product’s technology, materials, mechanics and the user experience into one cohesive product. Each component should be considered not just for its functionality but also for its contribution to the product aesthetic. Striking this balance will require product designers to consider both utility and beauty, with neither one taking precedence over the other. Through careful development and testing throughout the product design process, product makers can achieve this.

The importance of user testing during the product development process

User testing plays a critical role in product design. By integrating user research into the product development process, product teams are able to gain insights about how an end product can best meet users’ needs. User feedback helps product teams identify potential flaws that can be addressed early on in the process, and it also allows product teams to receive feedback from a diverse user group who might be experiencing the product in different contexts and therefore have a different user experience. Furthermore, user testing allows product teams to understand usability issues and prioritize which features should be added or removed in order to make the product better. Ultimately, user testing is an essential tool for helping product teams create products that are designed with their intended end user in mind.

How to take into account the manufacturability of a product when designing it

When product design is being considered, it is important to keep manufacturability in mind. A product must be designed with its eventual production process in the forefront. Part of a product designer’s role is to anticipate production complexities and consider cost-effective solutions. Ensuring that design decisions take into account limitations of the final product’s budget and what resources are available as part of the manufacturing plan, as well as how these limitations and resources can be leveraged to produce an optimally manufacturable product, can help prevent delays and expenses further down the line. Therefore, product designers should consider the obstacles their product will face prior to fabrication in order to make sure the product can be manufactured without problems.

With years of experience in engineering and manufacturing product design, we’ll work with you every step of the way to create a product that meets your needs and exceeds expectations. We understand how crucial it is for products to be designed quickly yet efficiently, and our team will ensure that everything meets your requirements while still maintaining quality control standards.

If you need help with any aspect of the product development process, reach out to Rosti. We specialize in taking products from concept to reality and our team would be happy to assist you.

Get in touch

We are only a message away.

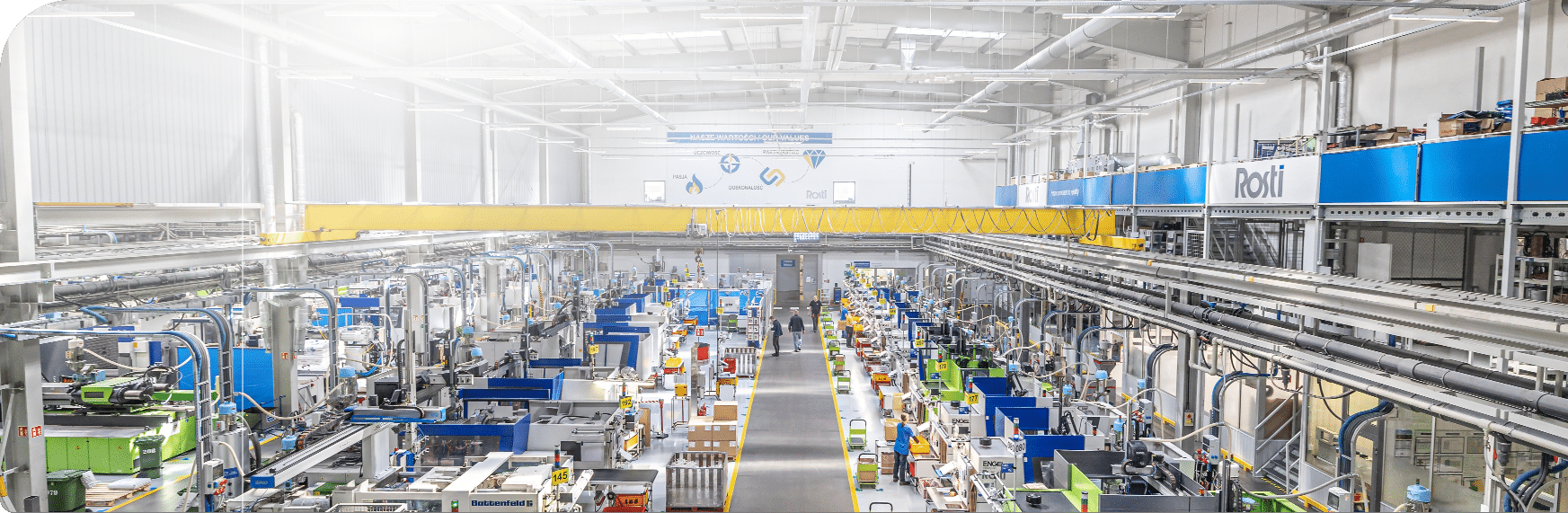

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.