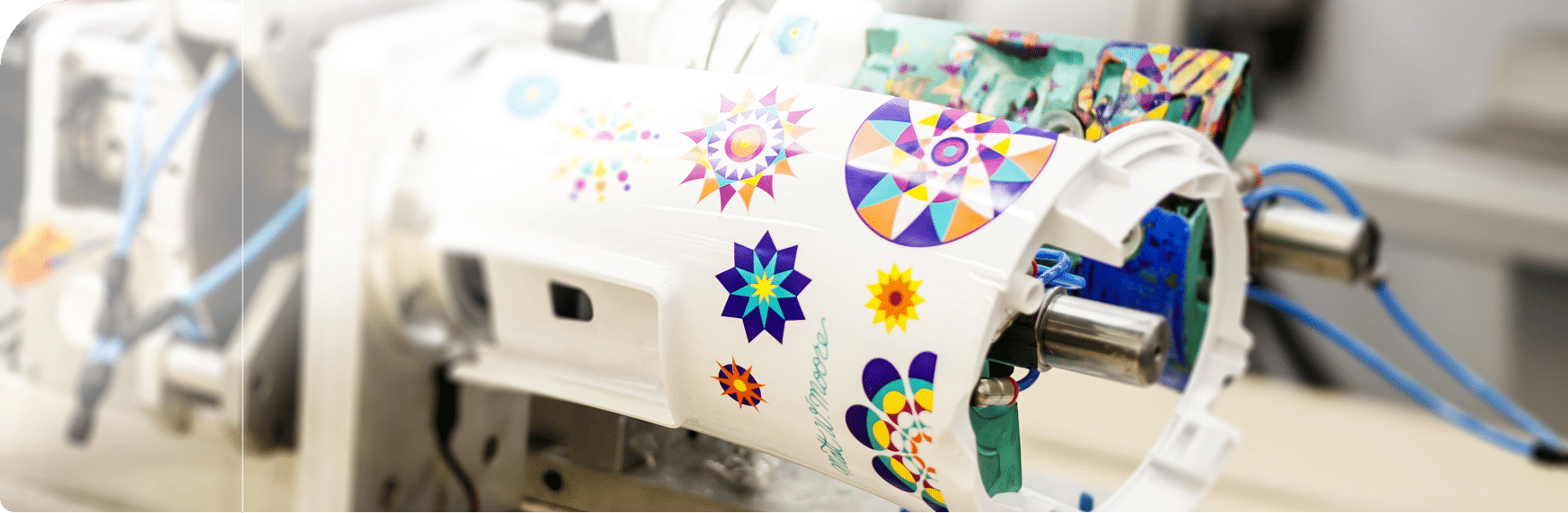

In-Mould Decoration

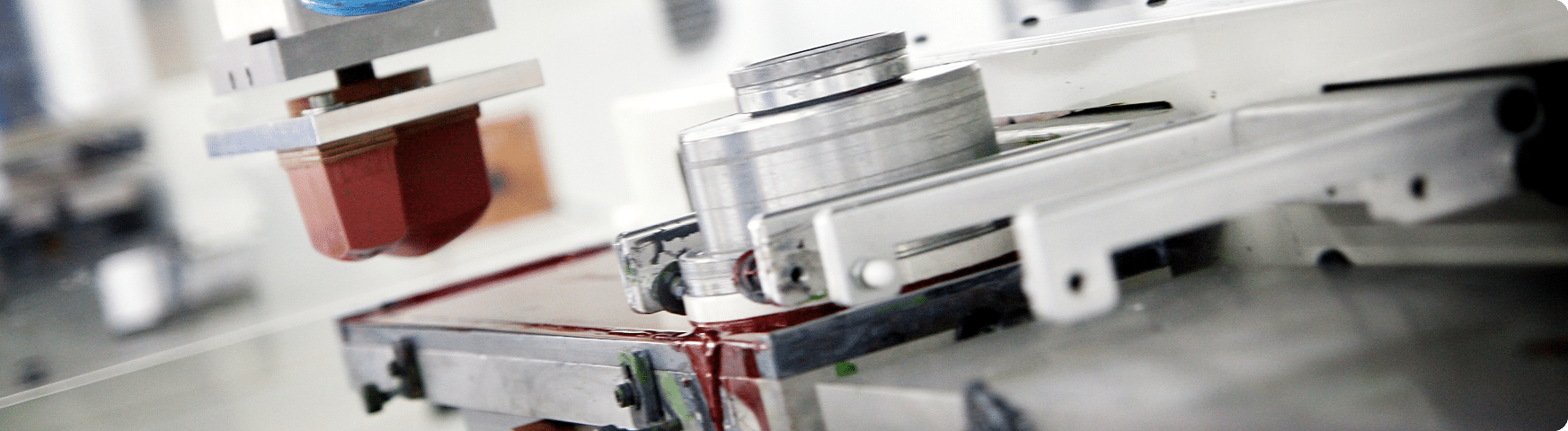

Rosti’s in-mould decoration (IMD) technology and processes gives you the freedom to incorporate intricate and colourful graphics into your products. Following years of research and development, we’ve fine-tuned a process that is efficient, reliable and cost-effective.

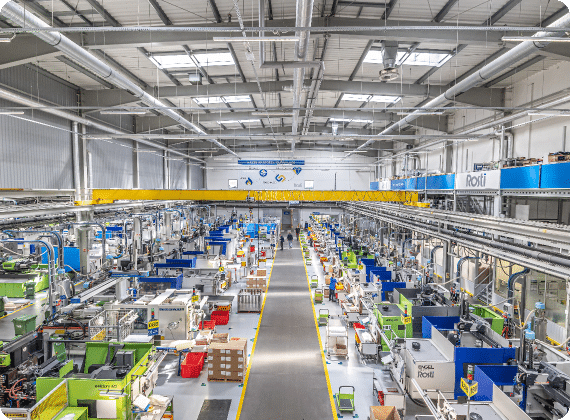

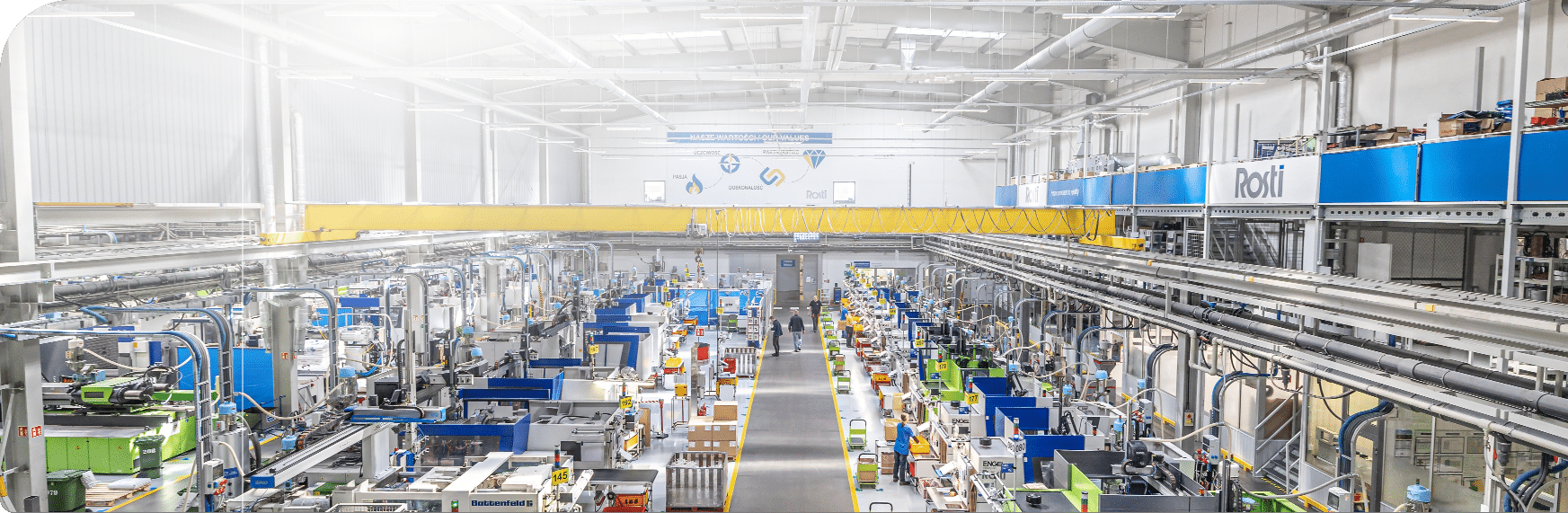

Through continual refinement of in-mould films and processes, we’ve achieved an IMD technique that offers high-precision and cost-effectiveness, available at various global sites. The Rosti method not only streamlines your production process but also decreases operational costs, all the while maintaining superior image quality.

Case Study

Engineering Innovation in IMD

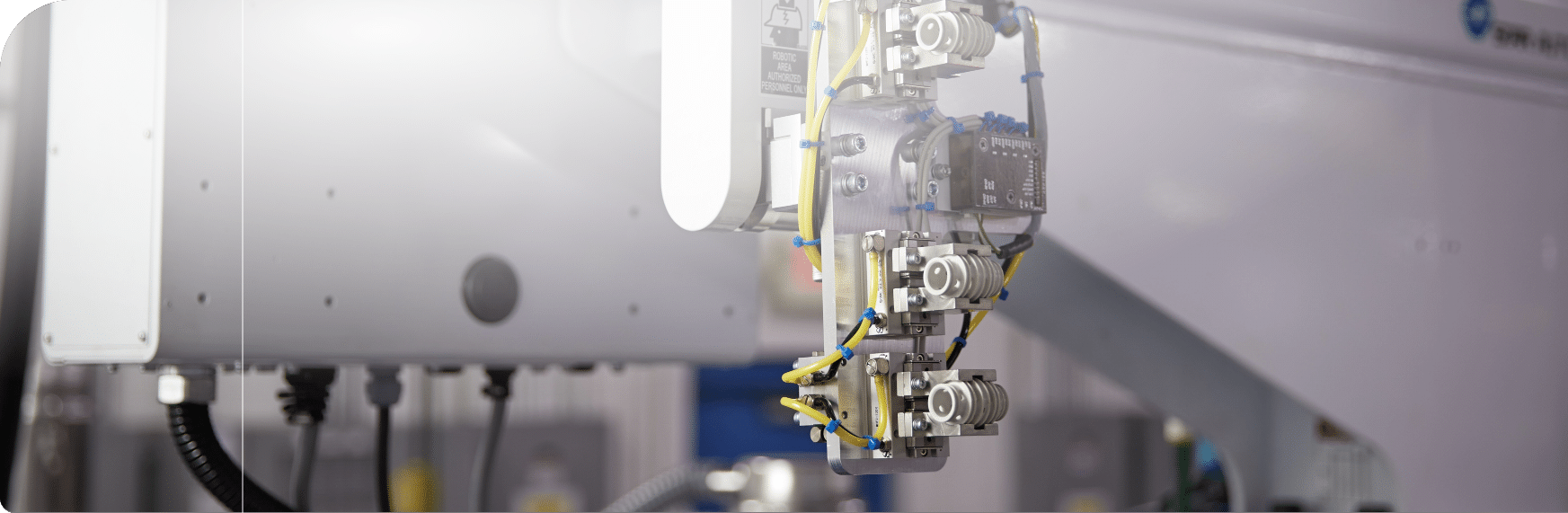

Our dedication to pushing the limits of IMD has led to groundbreaking collaborative efforts with customers and suppliers, delivering solutions previously considered impossible, including challenges involving geometric ratios.

Rosti China successfully implemented a new in-mould decoration (IMD) manufacturing cell for a long-standing customer, introducing an enhanced level of cosmetic design beyond what conventional painting or plating processes can offer. Traditionally suitable for flat geometries, IMD posed unique challenges for the complex 3D components in focus, with an impressive stretch ratio exceeding 45%.

Our approach involved rigorous risk assessment and potential failure mode analysis, treating the initiative as a distinct technical development project separate from the mainstream new product introduction programs. We navigated challenges related to stretch ratio, resin, and part flow length.

Critical factors included:

Stretch ratio complexities were addressed by analysing high and low stretch areas in our part’s three-dimensional curves. Resin, a high-temperature engineering polymer (Polybutylene terephthalate (PBT) + glass fibre content), was optimised through Rosti’s advanced injection mould flow simulation ability. The thin wall geometry and resin combination resulted in high injection temperatures and pressures, which were mitigated by Rosti’s digital analysis experience.

Following extensive digital development and scenario analysis, Rosti confidently transitioned to physical tooling and development. From launching steel tooling to having proof of concept and a production part process approved took less than three months. This remarkable timeline was possible due to a deep understanding of process difficulties, robust simulation models, and commitment to innovation, aptly illustrating Rosti’s ‘concept to reality’ philosophy.

For more information on this case study click here