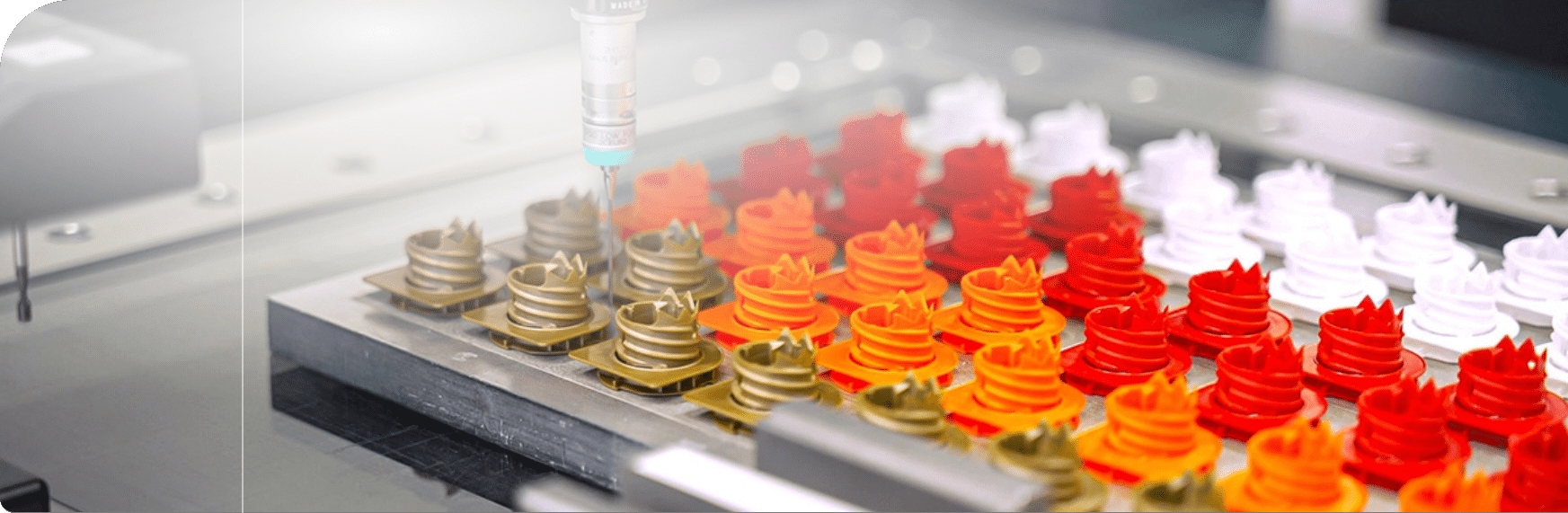

Material Selection for Plastic Injection Molding

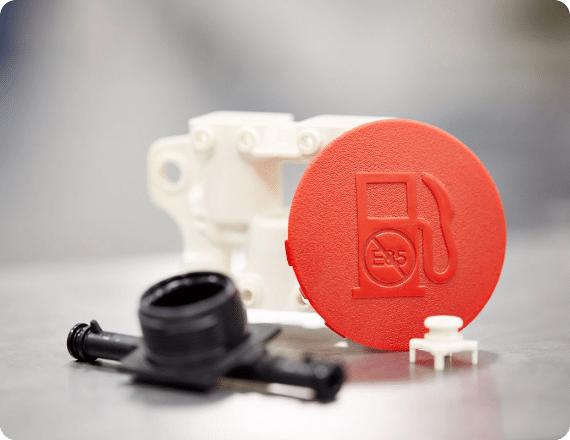

Material selection is a critical aspect of plastic injection molding. The right material can ensure that a part meets its design requirements, performs well in its intended application, and is cost-effective to manufacture.

In recent years, the need for careful material selection has become even more important. This is due to a number of factors, including:

- The increasing complexity of part designs. Many modern plastic parts are complex and require materials with specific properties, such as high-temperature plastics or exotic resins.

- The growing demand for sustainable materials. Many businesses are now looking for ways to reduce their environmental impact, and one way to do this is to use sustainable materials in their products.

- The global supply chain challenges. The COVID-19 pandemic and weather events have disrupted global supply chains, making it more difficult to obtain certain materials.

Rosti’s Expertise in Material Selection

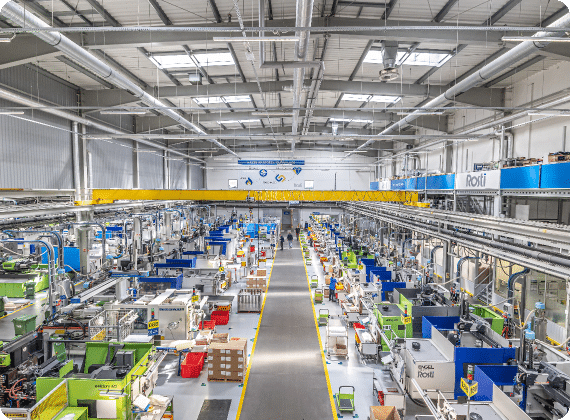

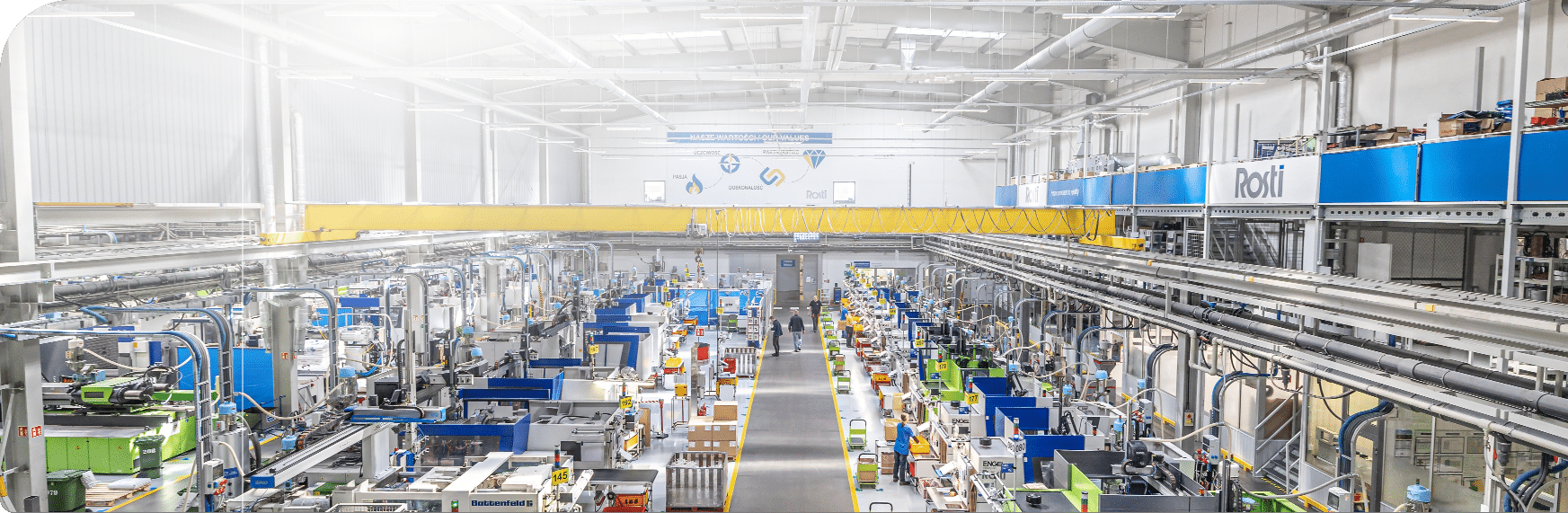

Rosti has extensive experience in material selection for plastic injection molding. We have a team of experts who can help you select the right material for your part, taking into account all of the factors mentioned above. Our global locations provide us with stable material supply chains with inter-company support, allowing us to offer a suite of moulded resin options that have been tested and validated to meet our customers demands.

For more information on material selection for plastic injection molding, please visit the following resources:

Get in touch

We are only a message away.

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.