Metal to Plastic Conversion Services

The world of plastic injection moulding is constantly evolving, with material innovation serving as a key driver of product development and manufacturing processes. One noteworthy trend that’s reshaping the industry is the transition from traditional metal parts to advanced, lightweight plastic components. This shift is bringing a host of benefits across industries, ranging from increased design flexibility and weight reduction to improved sustainability and eco-friendliness.

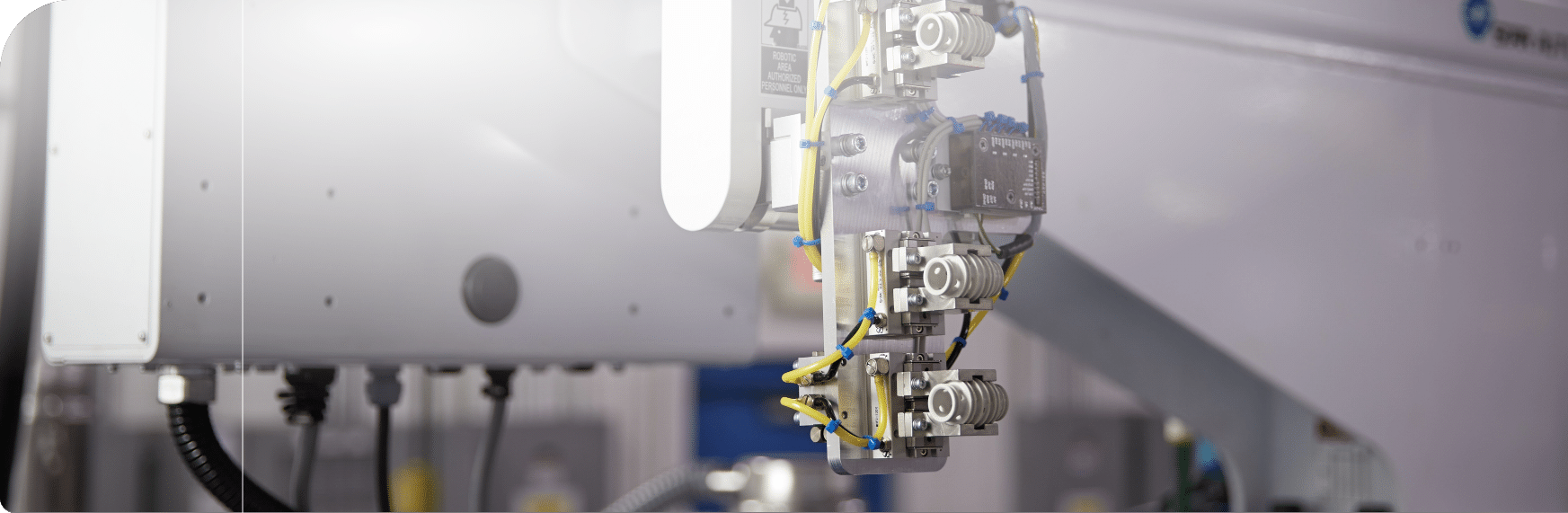

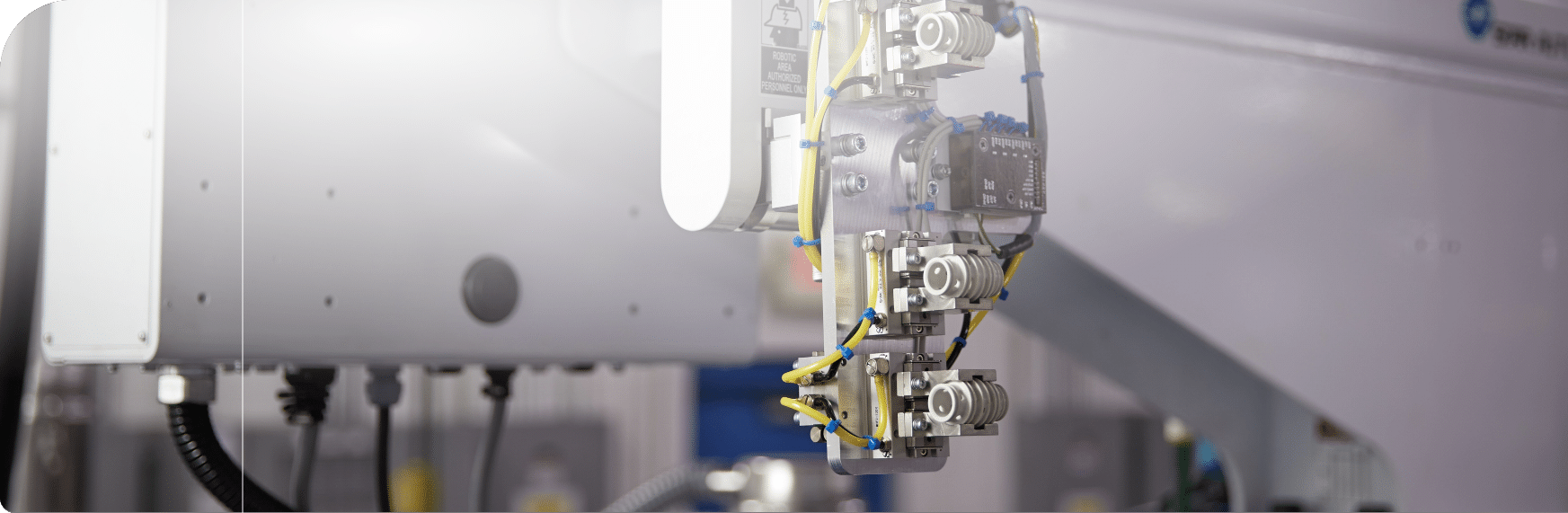

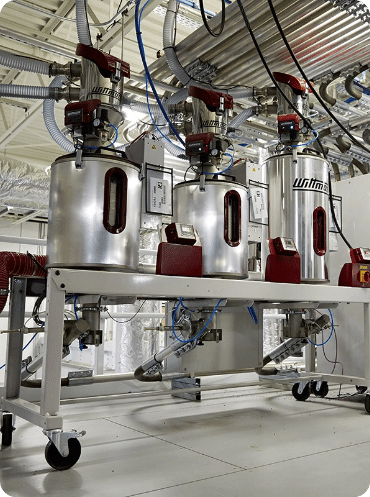

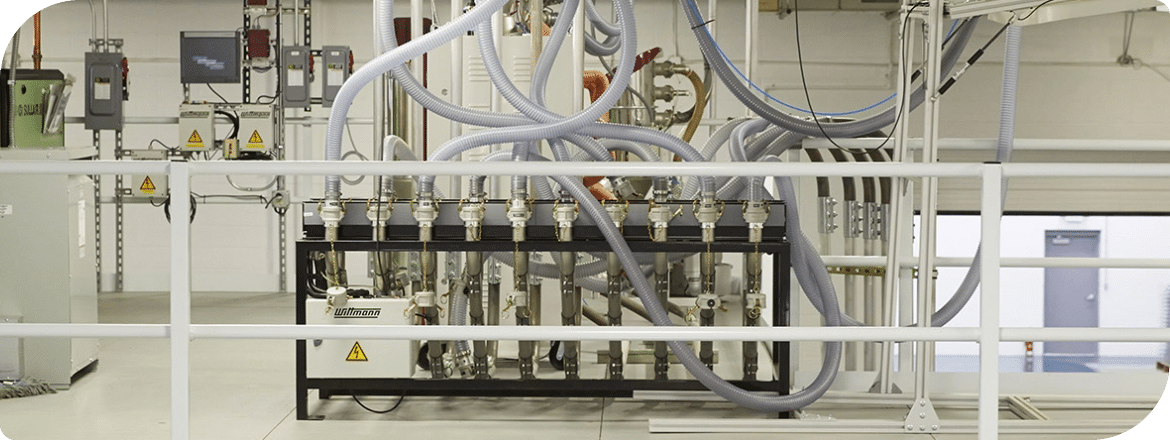

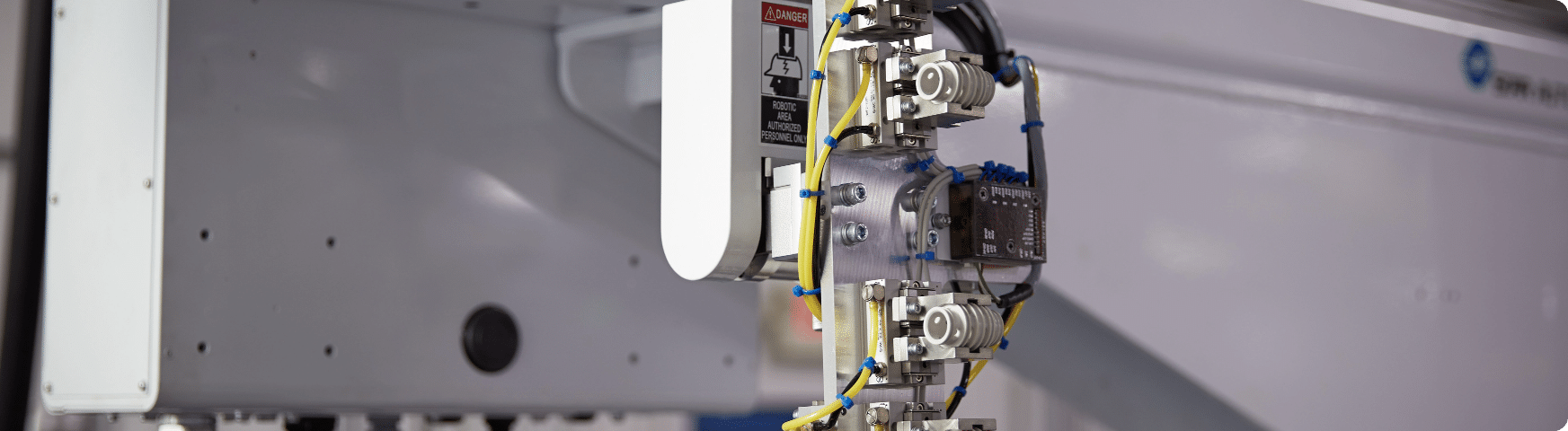

At Rosti, we’re proud to offer expert metal to plastic conversion services that can help you unlock significant cost savings and performance benefits. With our cutting-edge technology and rigorous quality control standards, we’re able to deliver top-quality plastic components that match or exceed the performance of their metal counterparts, all while being more cost-effective and durable.

Material Selection for Product Integrity

Transitioning from metal to plastic does not mean compromising on product integrity. In fact, with our expert guidance, this conversion can even enhance the quality of your product. We carefully assess your product design and evaluate its compatibility with injection molding, ensuring that the transition is smooth and the final product is up to standard.

Metal to Plastic Conversion Cost Advantages

Opting for a metal to plastic conversion can lead to substantial cost savings. Not only does plastic tend to be a more cost-effective material, but its lighter weight also helps reduce shipping costs. Moreover, complex shapes that would be challenging to create with metal can easily be molded with plastic, providing additional product design options and reducing manufacturing costs.

Plastic components often outlast their metal counterparts, resulting in further savings over the product lifecycle. Whether it’s automotive parts, aviation components, or even everyday items, converting to plastic can lead to a notable increase in cost-effectiveness.

If you’re considering a metal to plastic conversion for your product, our experienced engineers at Rosti are available to discuss your options and guide you through the entire process – from concept, design, material selection, optimisation and tooling. We have numerous examples of successful conversions across a wide range of industries, which we’re happy to share and demonstrate the cost, weight, and performance benefits of switching to plastic components.

To learn more, explore our comprehensive – Metal to Plastic Conversion Guide

Expert metal to plastic conversion services that can help you unlock significant cost savings and performance benefits.

Get in touch

We are only a message away.

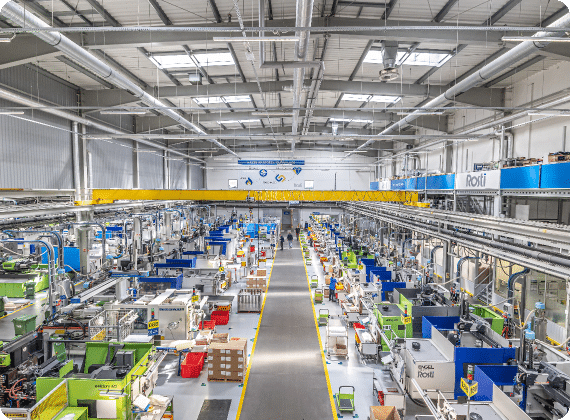

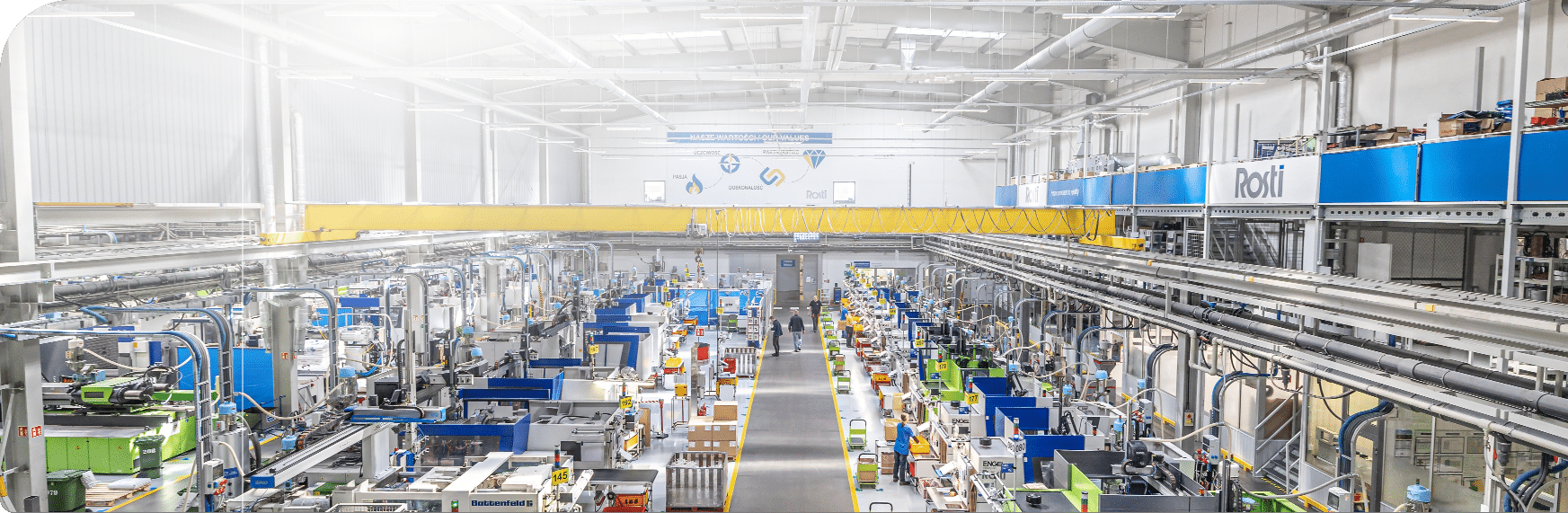

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.