Multi-Shot Injection Moulding or 2K Moulding

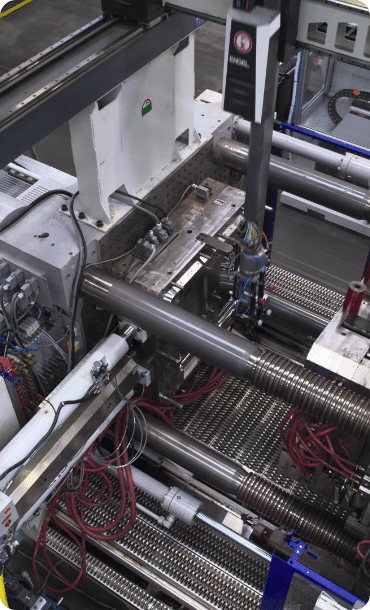

2k moulding or multi-shot injection moulding is a powerful technique that offers cost savings and efficiency gains to produce a quality product.

At Rosti, we take pride in our ability to deliver top-notch moulding solutions, including multi-shot and 2K, for your plastic manufacturing needs. With years of experience and a commitment to excellence, we believe we are the best choice for your project.

Expertise in Tooling Design

and Process Engineering

We believe the two key parameters to a successful product are expertise in tooling design and process engineering capabilities.

Tooling Design

Our hundreds of combined years of experience in tooling design and expertise in simulation include being rated in the top 10% in the world for mould-flow expertise. This level of expertise allows us to get your tooling design right the first time, at speed, utilizing the capabilities at our global innovation centre.

Process Engineering

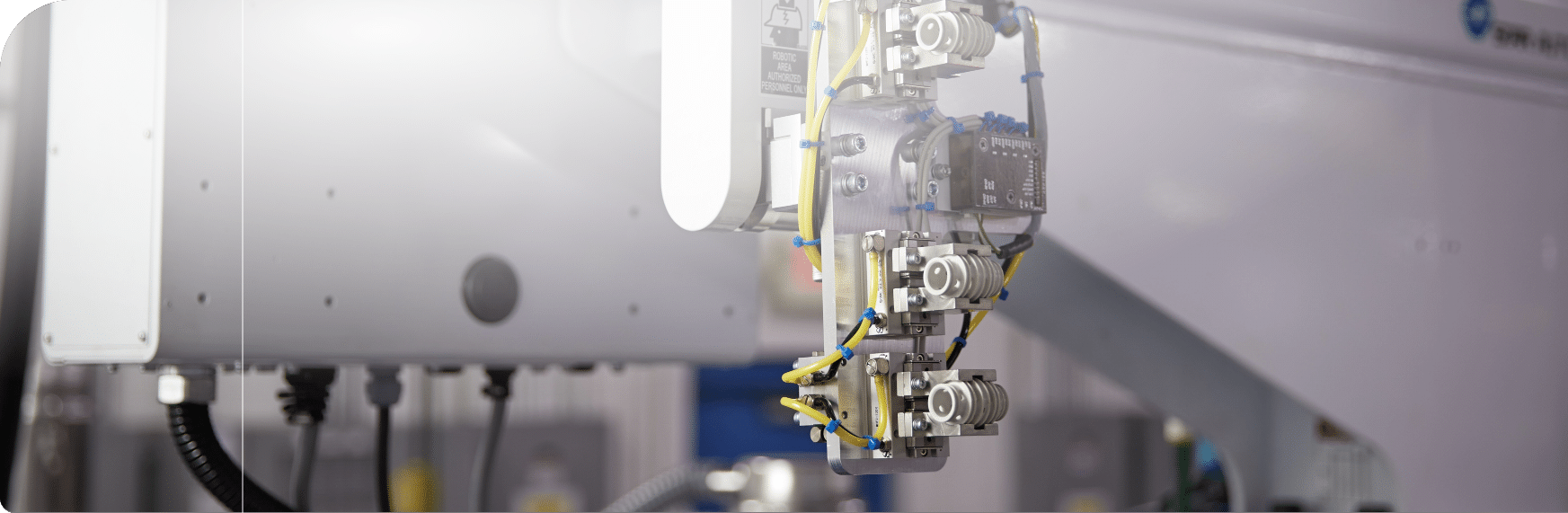

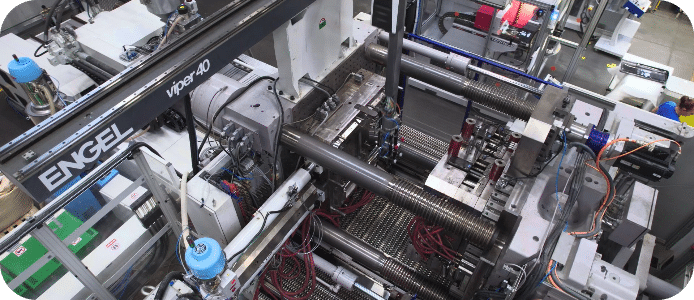

Multi-Shot Injection Moulding involves the simultaneous use of two different materials, two temperatures, and two different pressures. Such complexity demands a different level of process engineering capability. This is where Rosti shines.

With years of experience and continuous refinement, we understand the intricacies involved in controlling a complex system to achieve the highest quality results.

To maintain our high standards, we conduct an annual benchmark assessment. This assessment helps ensure that our engineers are up-to-date with the latest techniques and technologies, ensuring that your project benefits from the most advanced process engineering capabilities available.

Choose Rosti for your multi-shot or 2K

moulding needs

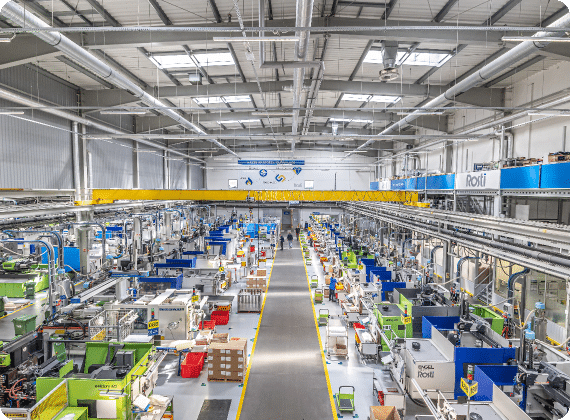

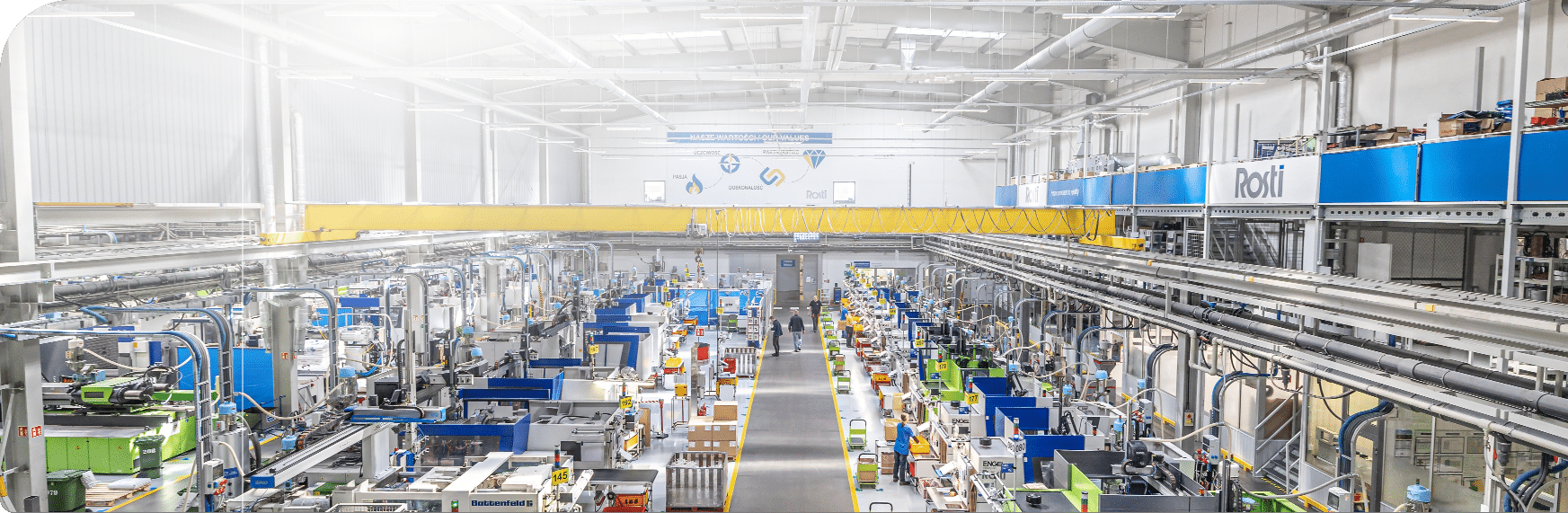

All of Rosti’s manufacturing sites have cutting-edge facilities capable of meeting the technical requirements of the most complex multi-material projects. With over 70 years of experience, our state-of-the-art simulation capabilities and global innovation centre, ensures that your tooling design is done right the first time, with speed and precision. Additionally, our advanced process engineering capability, honed through years of experience and supported by our technical academy, guarantees that we can handle the complexities of multi-material, multi-temperature, and multi-pressure scenarios.

At Rosti, we have the knowledge, skills, and resources to deliver the highest quality results for your project.

We understand the intricacies involved in controlling a complex system to achieve the highest quality results.

Get in touch

We are only a message away.

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.