Why Choose Rosti for Plastic Injection Moulding Services?

At Rosti, we combine over 80 years of experience as a plastic injection moulding company with the latest technology. This allows us to deliver precise solutions for industries such as medical, automotive, and consumer electronics. With ISO-certified facilities in Europe, North America, and Asia, we deliver high-quality, environmentally responsible production in line with the EU’s CSRD. From rapid prototyping to large-scale manufacturing, Rosti delivers flexible, sustainable, and reliable plastic injection moulding services designed to fit your needs.

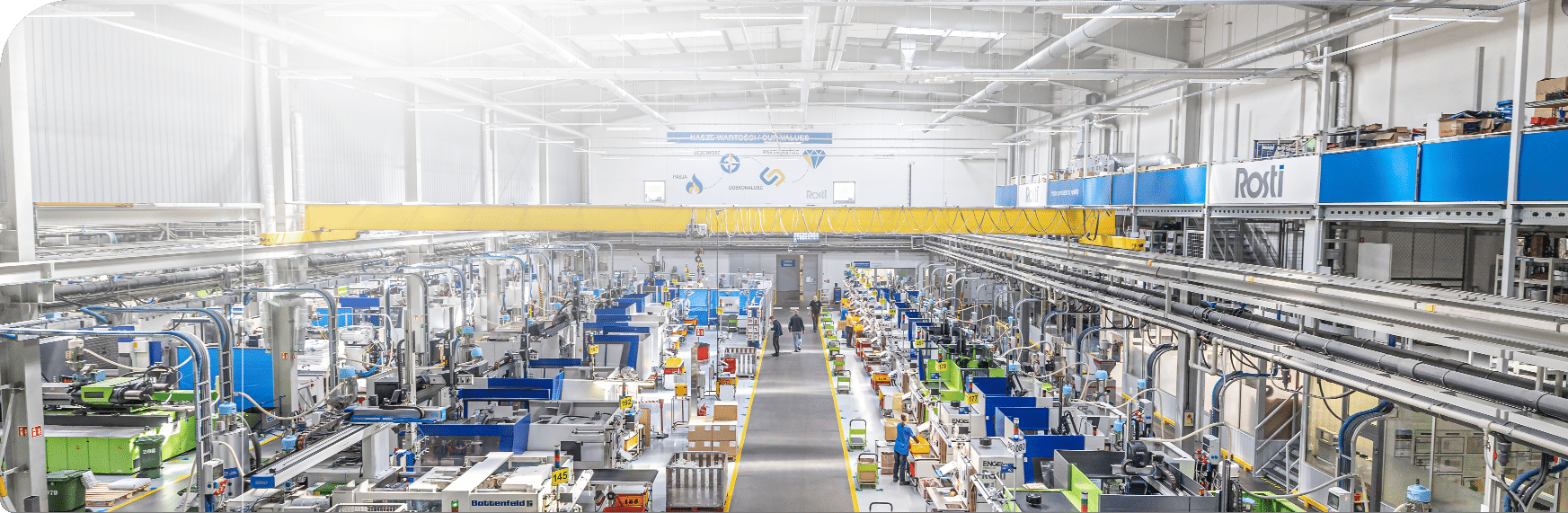

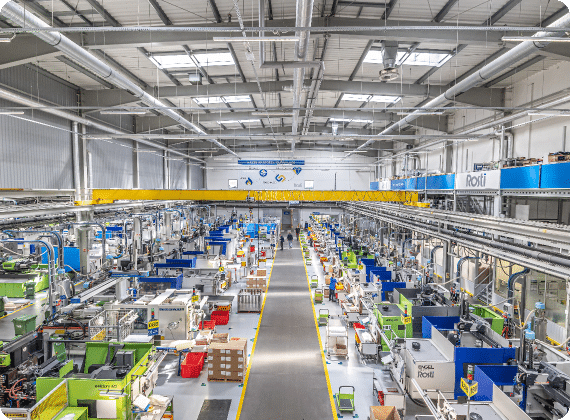

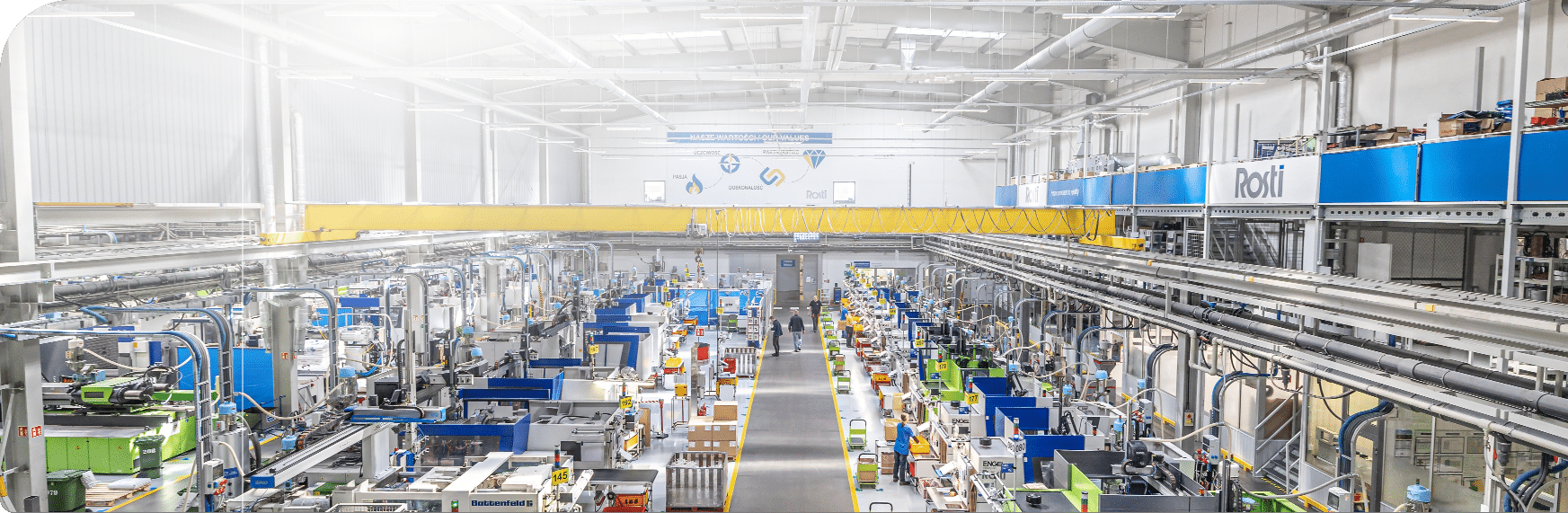

500 Plastic Injection Moulding Machines in Thirteen Sites

At Rosti, we operate over 500 advanced injection moulding presses across nine countries, giving us the flexibility to manage projects of all sizes efficiently and effectively. Every year, we produce millions of high-quality plastic parts – from small, simple components to large, complex assemblies – reflecting our commitment to excellence.

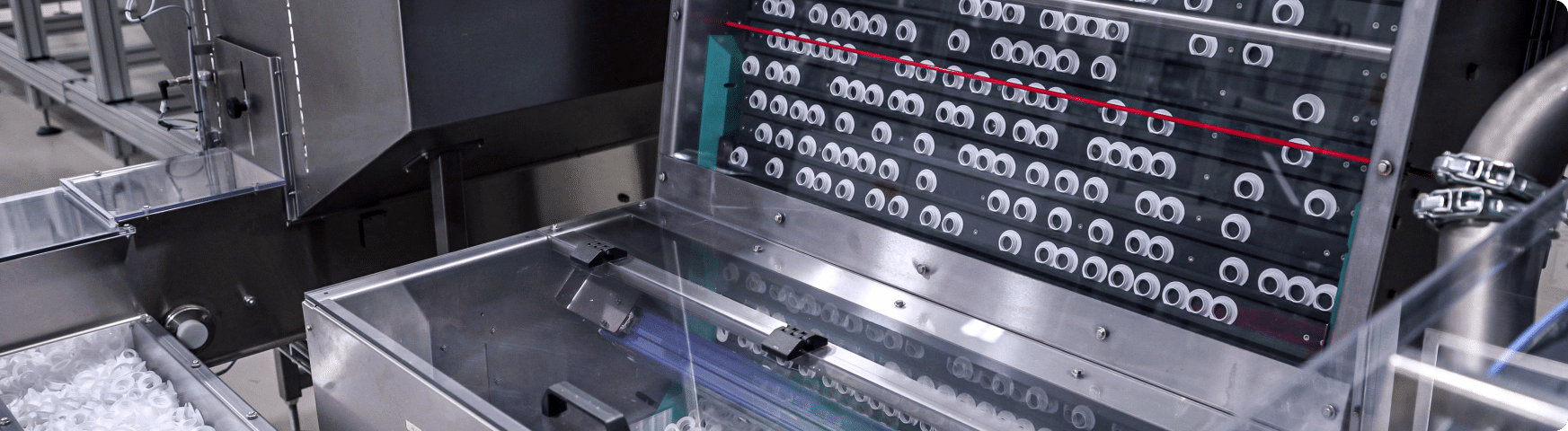

We also work with a network of over 50 experienced toolmakers across nine countries, ensuring the right tool for every project. Whether it’s a simple single-cavity mould or a complex 72-cavity tool, we deliver top-quality results with cost-effectiveness in mind.

What is a Plastic Injection Moulding Company?

A leading plastic injection moulding company specialises in transforming innovative designs into components at scale. Comprehensive, end-to-end capabilities extend beyond traditional moulding. The company works closely with customers from concept to completion, often offering:

- Product design and engineering – Optimising plastic part designs for efficiency, manufacturability, and cost-effectiveness.

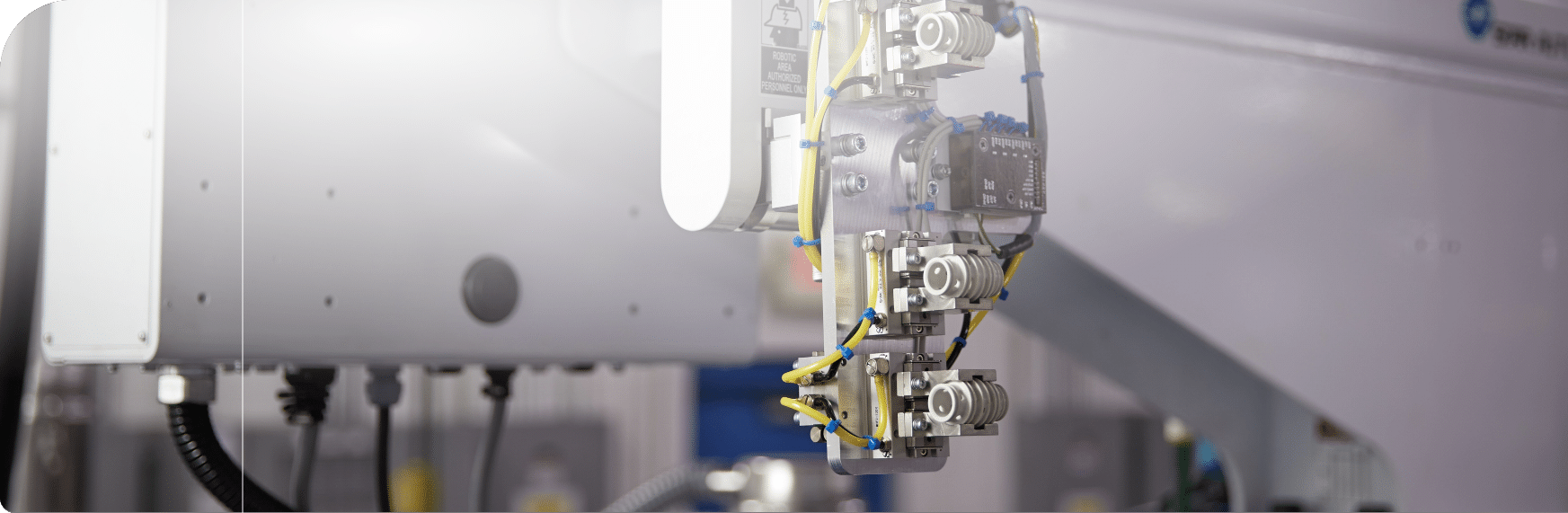

- Tool design and manufacture – Developing precision steel or aluminium moulds for plastic components using advanced engineering and automation.

- Material expertise – Selecting the right polymers to meet mechanical, aesthetic, and sustainability requirements.

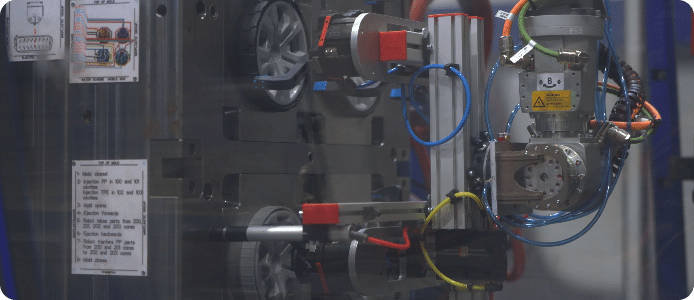

- Production and process optimisation – Operating state-of-the-art injection moulding machines for reliable, high-volume plastic production.

- Value-added services – Including assembly, decoration, surface finishing, and rigorous quality control for plastic parts.

The Plastic Injection Moulding Products

At Rosti, we specialise in delivering high-precision plastic injection moulding products tailored to meet the diverse needs of industries such as medical, automotive, consumer goods, and industrial applications. Our extensive capabilities encompass a wide range of manufacturing processes, ensuring that we can produce components that meet the highest standards of quality and performance.

Tony Austin, European Technical Director at Rosti:

“The Rosti Way exemplifies our core values; Passion, Integrity, Partnership and Excellence. These values guide us in everything we do.”

Except from traditional plastic injection moulding, we offer a variety of injection moulding techniques to accommodate different product requirements:

Solutions for Your Industry

Our plastic injection moulding solutions are trusted across a wide range of sectors that demand high-performance, reliable polymer components.

Automotive

Precision interior and exterior components, functional connectors, and lightweight structural elements designed to meet strict automotive standards.

Medical

Biocompatible parts, disposable instruments, and components suitable for cleanroom environments, supporting patient safety and regulatory compliance.

Packaging

Durable, lightweight packaging components, closures, and containers optimised for functionality, protection, and aesthetic appeal.

Domestic Appliances

High-quality housings, functional parts, and ergonomic components for appliances, combining durability, design, and user-friendly performance.

Industrial Applications

Robust housings, protective covers, and mechanically resilient parts engineered to withstand demanding operational environments.

Sustainability in Every Step Solutions

Sustainability is part of everything we do – from product design to manufacturing and the finished product. We recognise both our responsibility and opportunity to make a positive environmental impact across the plastics industry. We design products with sustainability in mind, select the right materials, optimise processes, and reduce waste, influencing the entire value chain from raw materials to end-of-life solutions. Across our global operations, we implement energy-efficient machinery, recycling programs, lightweight and repairable designs, and the use of bio-based or recycled materials. Working closely with our customers and partners, we support a circular economy and create a more sustainable future. Sustainability is not just a goal – it guides every step we take.

Unparalleled Manufacturing Support & Customer Satisfaction

Our commitment to excellence at Rosti extends beyond manufacturing, as we provide comprehensive manufacturing support to ensure success for our customers. We offer engineering and design support, a digital innovation lab, and educational initiatives to keep customers informed regarding the latest technologies. Our customer care centers prioritise customer satisfaction, while our use of digital simulation and material selection expertise helps optimise product performance. Our well-defined processes, production transfer capabilities, and unwavering commitment to quality make Rosti a reliable partner for businesses seeking manufacturing support.