Supply Chain Management

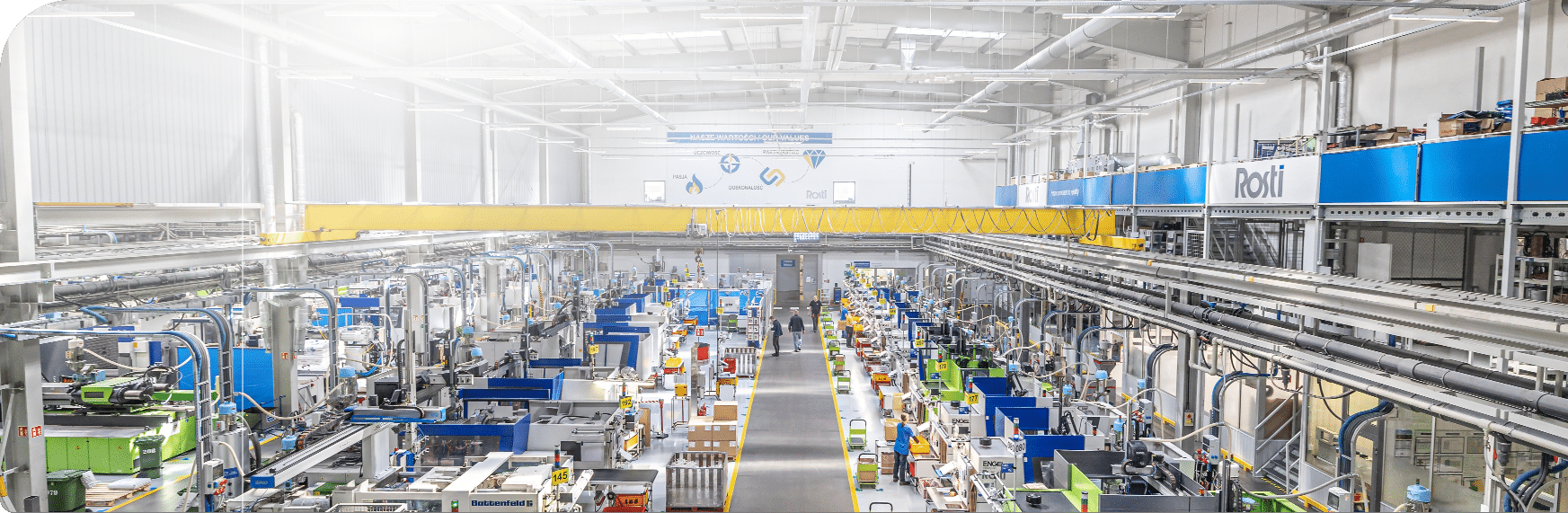

With a network of suppliers covering 27 countries and dedicated quality assurance teams, Rosti provides a streamlined, flexible supply chain that ultimately reduces your production costs and lead times. We partner with you through every aspect of the process.

What is Supply Chain

Management?

Supply chain management is the management of supply chain goods and financial transactions related to an individual product and service. At Rosti, supply chain management requires managing global supply chains, customer demand, supply chain partners, demand management and much more!

Global reach. Local focus.

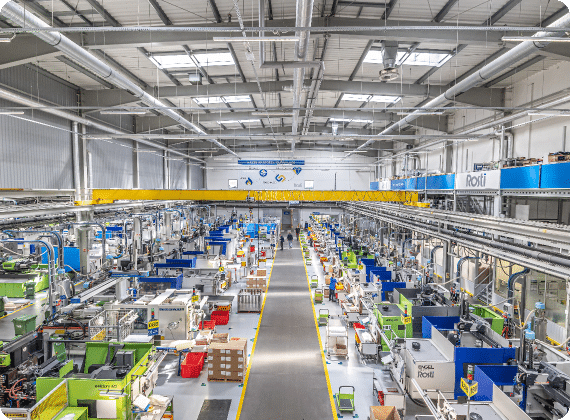

When producing individual components, pre-assembled parts, or ready-to-sell products, a reliable, flexible, and economical supply chain is essential. Rosti offers this through our global network of suppliers, cultivated over decades and consistently evaluated for quality and efficiency. This ensures a dependable and cost-effective supply chain for your manufacturing needs.

Our global presence enables us to reduce lead times while sourcing locally, providing a strategic advantage in procuring essential components such as resin, electronics, metal parts, and packaging. We offer comprehensive support in all aspects of supply chain management, including quotations, logistics, warehousing, and more. Our commitment lies in finding solutions that ensure value and dependability for the end customer.

Rosti’s global reach

27 Suppliers worldwide

76 Countries served

12 Manufacturing sites worldwide

Why is Supply Chain Management important?

Supply chain management is important for a variety of businesses because of the potential benefits. For instance, control of manufacturing processes helps increase product quality and reduces risks in recall. Control of ship procedures can play a key role in the service level of customers by preventing expensive inventory shortfalls and periods. Overall, supply chain management offers a multitude of options to businesses to boost their earnings margins, a major challenge, particularly to large and internationally-focused companies.

5 Parts of Supply Chain Management

Using a supply chain management approach to a project can be a critical part to achieving high quality results. Sourcing means working with vendors on the supplies needed for the entire production process. Supply planning is a crucial step in the supply chain management process. When sourcing goods within a supply chain, it is crucial to understand the timeline of each product to ensure the chain is not broken.

The supply chain management process ends by supporting products and customers return processes to the supplier. Returns management - sometimes called reverse logistics - is when companies have to ensure that they are capable of accepting returned goods and correctly assigning returns for returns. The company is required to correct the situation if the customer isn’t happy with the products they are purchasing from the manufacturer.

The company must have the product put in the hands of the customer after the production and finalisation. The distribution process is usually seen to help build up brand image, because customers haven't yet engaged in the products. With strong supply chain management procedures companies possess robust logistics capabilities and supply channels for quick, safe deliveries. Ideally, it is necessary that backup systems or diversified systems of transport are provided if a transport system temporarily becomes unusable. Ensuring a safe and timely way to deliver goods is an important step in the chain.

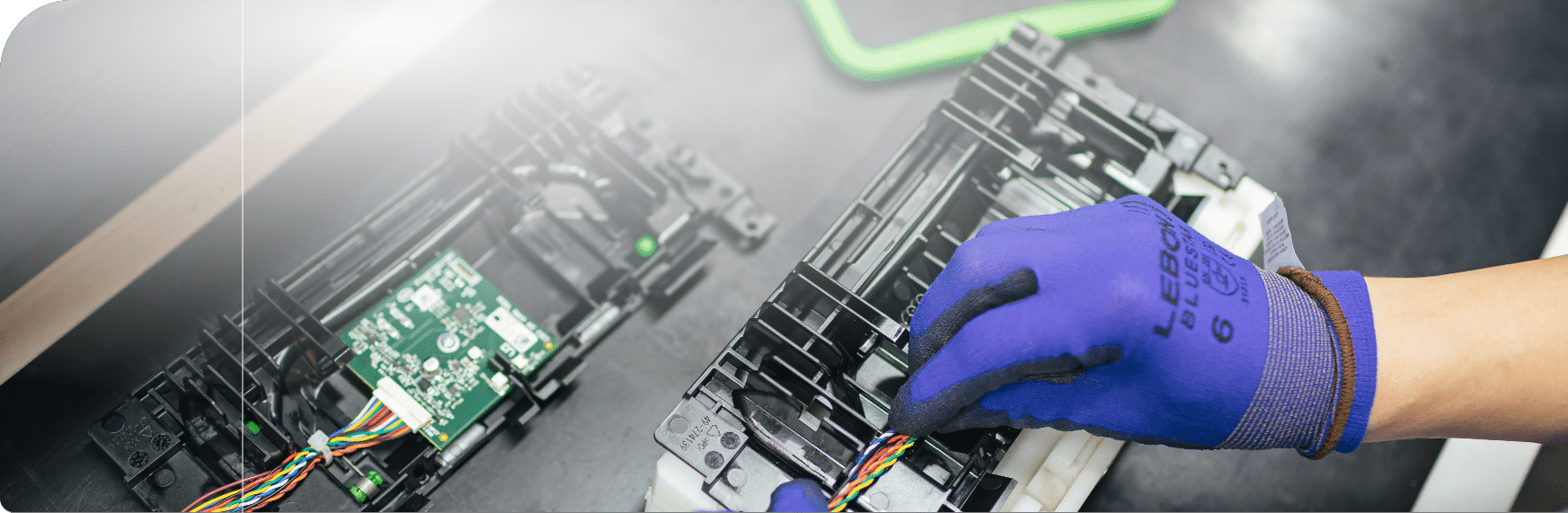

Effective manufacturing processes play an important role in supply chain management, however this is not the final step. Properly manufactured products are the final goal of the manufacturing process, but are not the last phase. After a product is manufactured, you must go through a series of tasks to ensure the product is working to meet customer expectations. Suppliers will go through a series of subtasks - assembly, testing, inspection and packaging for example.

Supply chain management usually starts with planning in order to meet customer demands. It is important to anticipate future demand and plan accordingly. These are the raw materials needed for each phase of production, capacity and limitations of equipment, as well as staff requirements throughout supply chain management processes. This advanced planning will help ensure an efficient supply chain.

Invaluable expertise in the injection

moulding industry

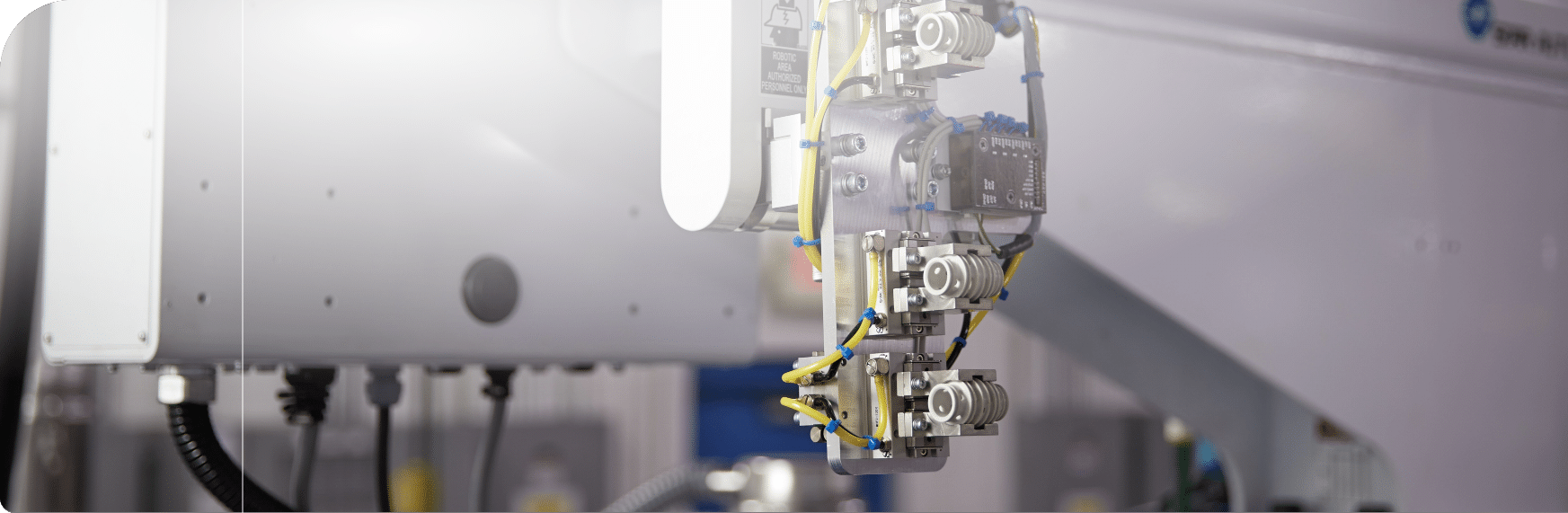

Any industry demands excellent project management across the entire supply chain. For injection moulding, strengths like strong oversight and managerial skills are vital. Expertise in tracking the project across the entire chain helps ensure high-quality production, efficiency, sustainability and ultimate success.

Successful supply chain management in the plastics moulding industry includes superior planning skills, efficient execution, and experience in global procurement, supplier sourcing, and delivery. The most critical features of the supply manager’s duties are further explained here:

Productive, strategic supply chain management requires robust attention to detail, along with an equally important overview of the entire supply chain process. This is a tricky balance to strike. On a day-to-day level, managers must control budgets and production costs, keep an eye on the logistics of the operations, and oversee processes required to stay on track. Tasks include scheduling and goal setting, inventory management and inventory planning, taking note of reducing costs where able and coordination across offices and suppliers.

While this attention to detail is essential, big-picture thinking encompasses an overview of the supply chain processes, supply chain performance and the strength of mind to predict and manage problems across the board. Keeping sight of the goal requires discipline and creativity.

Communication across the supply chain is also necessary. Effective supply chain management involves getting the right information to the right people, at the right time. Any issues that arise at any stage in your project’s process can be dealt with swiftly and efficiently when robust communication strategies are set in place. Strong communication provides the bridges between multiple sites and agencies, as well as minimizing errors that may create inefficiencies.

Communication is imperative between you, the client, and your supply chain manager, too. Our clients are kept informed at all stages of the process. From the beginning, where we assess your needs and expectations, and supply accurate and clear plans and proposals, to the bulk of the supply chain management tasks where we act as a bridge between you and your suppliers, production teams, engineers and designers.

Any third parties brought into the supply chain are thoroughly vetted and controlled. In successful supply chain management for the moulding industry, a high level of control is needed to maintain the precise standards and specifications of the project.

Allocation of tasks and resources to third-party suppliers is most successful when this ensures consistency across the product and the entire process, as well as essential design continuity. Supply chain managers standardise the procedures across the injection moulding cycle by choosing suppliers that are known, approved and regularly audited. Customer service must also come as standard in the plastics moulding supply chain, due to the many links.

Your project is important as a whole and not just as a series of tasks to manage and accomplish. Strong project management takes a view of the process from the initial order to production, shipping and evaluation. Effective management takes fluctuations and supplier/ consumer demand into consideration to form an overview of the workflow that may constantly change but will always be expertly controlled.

The logistics of the supply chain are important and often cause headaches for lesser-qualified project managers. Schedules in the plastic injection moulding industry are often very tight, with little room to manoeuvre. Deadlines must be met, otherwise the smallest hiccup can throw the project timeline out.

Professional supply chain management solutions handle all aspects of the project, including evaluation and assessment of the procedures and logistics. The supply chain manager should have a strong set of metrics with which to measure success against defined goals. This allows you, the client, to gain an overview of how the project is measuring up to your standards.

A value-adding partner throughout your entire production

It is essential to select an exceptional plastic injection moulding manufacturer with experience in supply chain management to supply this extensive skill set. Choose Rosti with our focus on performance standards, our expertise developed over many decades, and our attention to detail.

To truly unlock the benefits of our global supply network, it’s best to consult us as early in the production process as possible. By working alongside Rosti from the design stage, you get the benefit of an experienced partner capable of foreseeing the challenges and opportunities ahead. With project managers who can grasp the full scope of your enterprise, we can help plan and make sure the right parts and components are available when you need them.

Rosti provides an end-to-end service, supporting you every step of the way from concept to reality.

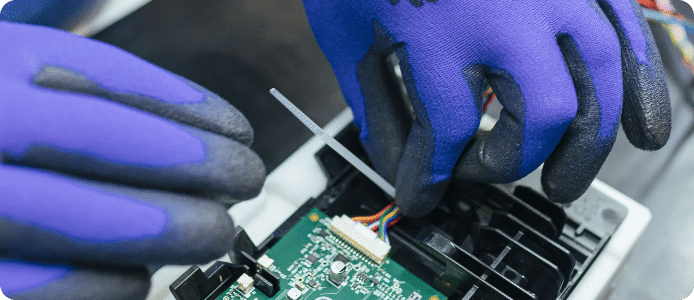

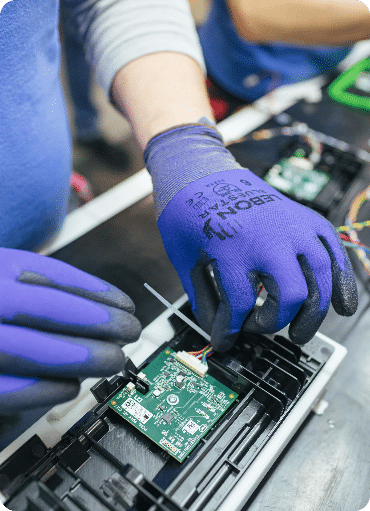

Quality assured materials and services

Rosti’s supplier quality assurance teams make certain that all materials, tools, electronics and services are appropriate for the needs of your product. We select and qualify every new supplier according to standardised procedures to make sure that every component and service is reliable and high quality. Regular measurement and testing ensure that suppliers continue to provide optimal materials and services. It is of top priority for us to manager supplier relationships.

By searching the world for the most reliable and highest quality suppliers, we make your manufacturing process smoother and more cost-effective.

Get in touch

We are only a message away.

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.