When customers face plastic injection moulding production challenges or want to relocate manufacturing closer to their markets, Rosti’s dedicated Production Transfer team provides the experience and structure needed to make it happen.

Tag: Our Process

What is Contract Manufacturing?

Not every company or agency has the resources, budget, or time to handle everything internally – no matter how ideal that may seem – especially in the manufacturing sector. Purchasing equipment, machinery, and specialised expertise can be expensive. That’s why contract manufacturing has become a widely used solution.

The Importance of a Unified Global Quality System in Medical Manufacturing

For medical device manufacturers, quality and compliance are non-negotiable. Regulatory requirements are becoming more complex, while speed to market remains critical for commercial success.

How are Rosti Group embracing AI in Injection Moulding?

Scott Dickson, Technology & Innovation Director at Rosti Group, shares his perspective on how we are embracing AI to enhance our global plastic injection moulding capabilities. From driving efficiency and improving quality to accelerating innovation across our global facilities, Scott explores the practical ways AI is shaping the future of manufacturing.

How are Rosti Group supporting customers with Renewable and Recycled Material Selection?

As companies worldwide commit to ambitious global reduction targets and science-based goals, there is a growing need to reduce emissions, adopt sustainable materials, and optimise design and energy use.

Supporting the Medical Industry in Limiting Time-to-Market through Innovation Capabilities and 72-Hour Concept-to-Reality Process

In the fast-paced world of medical device manufacturing, time to market is a decisive factor for success. The ability to design, manufacture, and deliver new medical devices at speed is crucial from the perspective of having an impact on patients, meeting regulatory requirements and the commercial success of a device.

Rosti UK Secures Exciting New Project with Abingdon Health

Rosti UK are thrilled to announce the award of a prestigious new project with Abingdon Health, a leading provider of single-use testers for both human and animal diagnostics. This is an exciting milestone for both parties as we embark on a collaborative journey towards innovation and excellence in the medical device industry.

Rosti – Your Dependable Plastic Injection Moulding Partner and Contract Manufacturer

A business you can rely on to continuously deliver the highest-quality product, engineering and service, focusing long-term collaborative partnerships. Our conservative financial approach ensures we will always be a dependable partner to our customers and enables us to operate from a position of stability. This approach continues to this day, with our secure position being bolstered by our relationship with our owner Nordstjernan, a Swedish family-controlled investment company.

4 Reasons to Consider Metal to Plastic Conversion

Since the introduction of engineering-grade resins and plastic materials in the 1950s, many parts previously fabricated from metal have been replaced by injection molded parts. On average, companies report an overall cost savings of 25-50% by converting to plastic parts, yet some manufacturers have resisted making the change.

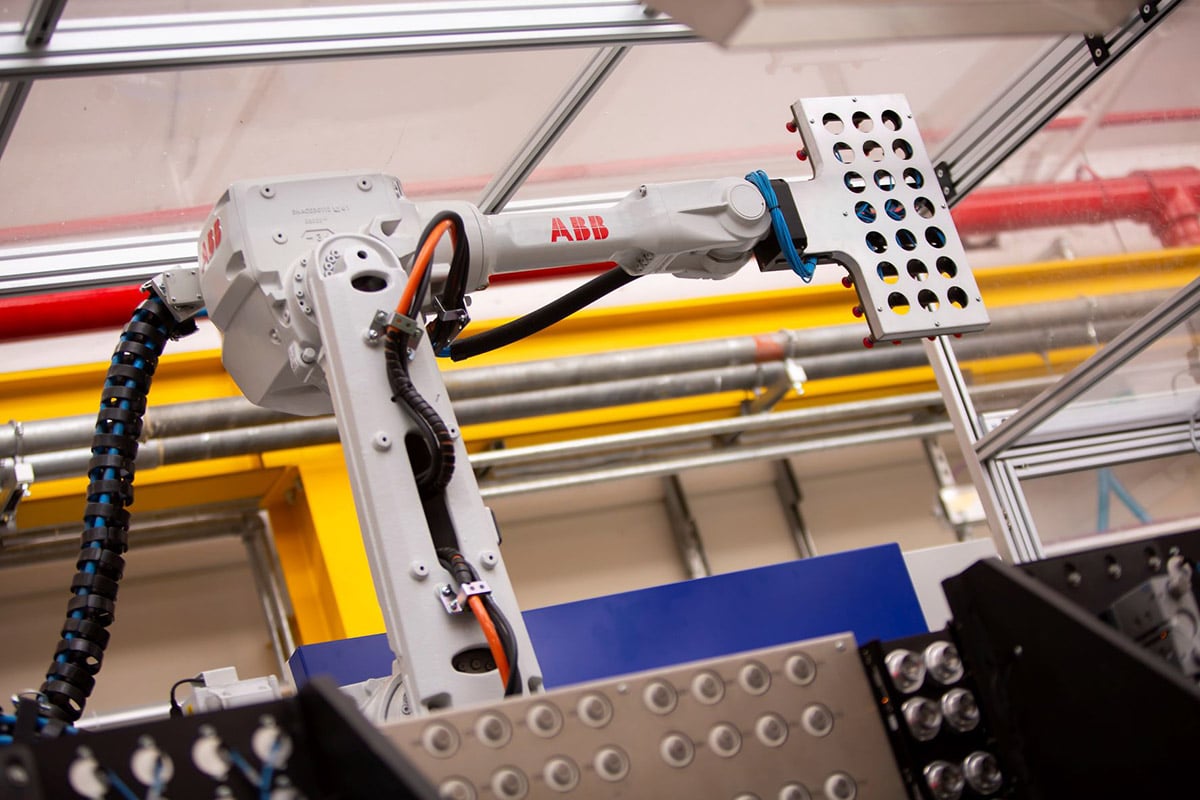

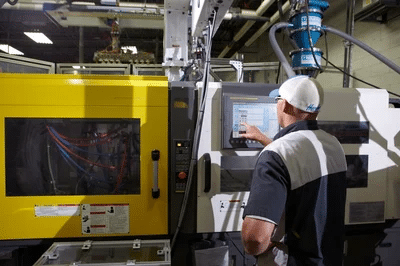

Advantages of Scientific Moulding Practices

Scientific molding practices are essential to achieving outcomes that deliver faster cycles, higher volumes, and a more efficient injection molding process. Implementing sound scientific principles can help with determining optimal molding conditions. Equipment and software that help monitor real-time production processes guide the scientific molding stages and provide a critical advantage. In addition, quality control issues can be avoided by having automated containment control and traceability for specific applications. From collecting data to machine maintenance, process development to resin characteristics, and much more – scientific molding helps identify efficiencies which result in greater value and better parts for customers.