Rosti Wisconsin has a prominent and progressive 34-year history in business, serving OEMs in the U.S. and beyond. Over the years, the Wisconsin locations have grown to include two state-of-the-art manufacturing facilities and a distribution centre, all located in Germantown, Wisconsin, totalling over 78,000 square feet.

Rosti Wisconsin | N116 W18271 Morse Drive | Germantown, Wi 53022

Rosti US Terms and Conditions

Facts & Figures

78,000ft² Facility

85+ Employees

Established 1989

Certifications

Take a look at our industry specific certifications from approved bodies, to ensure we provide you with guaranteed service.

International Standard for Quality Management (2015 - latest version)

International Standard for Medical devices (2016 - Latest version)

Our Capabilities

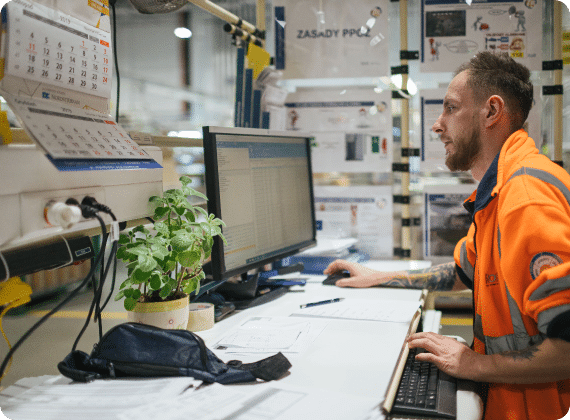

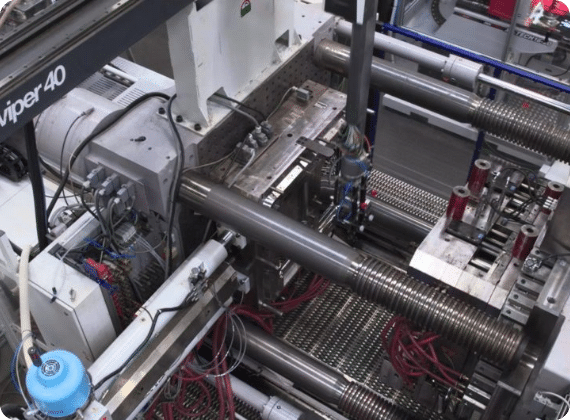

Rosti Wisconsin boasts state-of-the-art manufacturing facilities that lead the industry with their innovative technologies and efficient processes. With a monthly shipment of over 10 million parts to customers across the globe, the facilities are renowned for their cutting-edge automation techniques in insert molding, over molding and tray packing of highly sophisticated components.

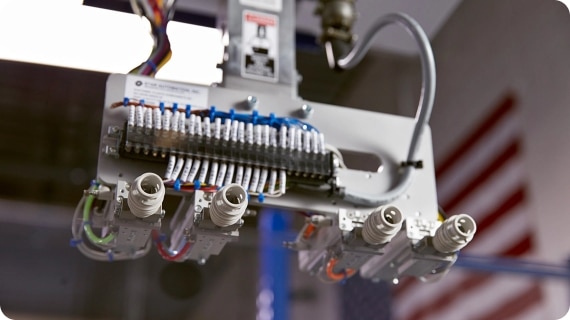

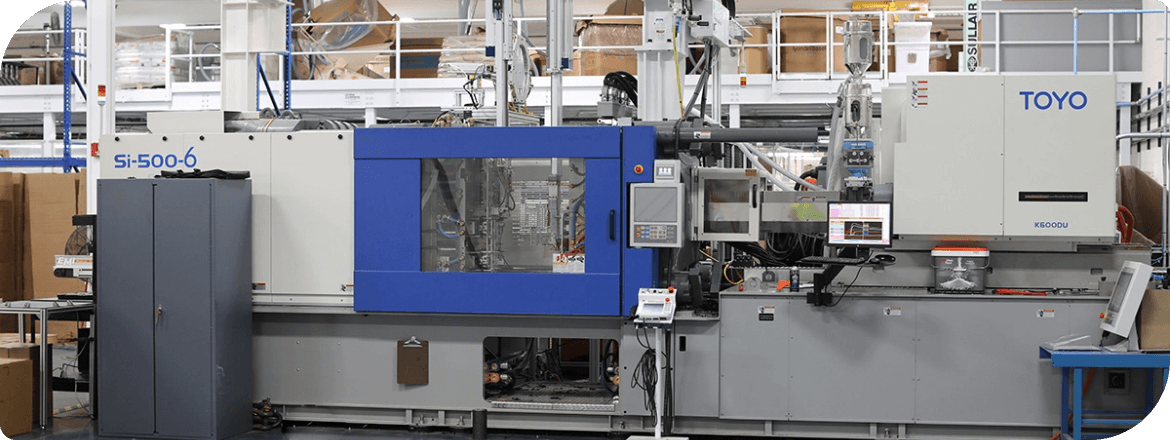

The facilities are equipped with advanced injection molding presses and a central material handling system that eliminates the need for direct labor. Its 81 fully-automated molding cells, ranging from 35 to 500 tons, are operated by a team of skilled engineers and technicians, utilizing patented lights-out manufacturing processes for maximum efficiency and productivity.

This, coupled with five and six-ton cranes and the ability for two-shot molding within a captive cell, makes Rosti Wisconsin a leading provider of highly engineered and top-quality components.

Our services

As a premier provider of design for manufacturing (DFM) services in North America, Rosti Wisconsin sets the standard for excellence in plastic part design, prototyping, injection mold design, and mold simulation validation. With the latest tools and technology at their disposal, the Wisconsin engineering team uses SOLIDWORKS Plastics Premium predictive II simulation software and RJG eDart process control systems to provide predictive insights into component design, streamlining the development process and reducing the time it takes to bring products to market.

As a full-service plastic injection molding provider, Rosti Wisconsin takes a data-driven, scientific approach to every aspect of their work, from material selection to part design optimization, tool design optimization, metal to plastic conversion, and much more. By using a systematic method and relying on proven data, they ensure the highest level of quality and efficiency in every project.

Our facilities

Rosti Wisconsin – Bunsen Drive

The Bunsen Drive facility has operated on a fully-automated, “lights-out” basis since its opening in 2011. After nearly four years in operation and peaked production capabilities, 2015 marked a notable year with a 23,000 foot addition. The Bunsen Drive facility now houses 35 manufacturing cells.

The fundamental premise of the manufacturing strategy at Bunsen Drive is to run the facility “lights out,” with no direct labor used to produce components. State-of-the-art material handling systems, part conveyance systems, and robotics allow parts to be produced without the need for human involvement. This is the growth strategy for Rosti and this is how the company remains globally competitive.

Bunsen Drive is the future of manufacturing and is in fact, one of its kind. The United States Government issued Rosti a patent to validate the processes that take place within the facility. Every detail from the lighting to the part conveyance system, has been meticulously planned. This attention to the little nuances of a manufacturing plant is what separates this facility from others in the world. Infrastructure expansions will set the stage for the additional production presses.

The acquisition of a five-ton crane now allows the facility to be outfitted with larger machines. This will provide Rosti and our customers the ability to spread the highly efficient manufacturing process across a wide array of press sizes, depending on demand. Rosti looks forward to Bunsen Drive being a key area of growth.

Rosti Wisconsin – Morse Drive

Since the company’s inception, Rosti’s Morse Drive facility has expanded from an original size of 10,000 square feet to its current size of 40,000 square feet. The facility houses 46 fully-automated manufacturing cells (35 – 400 ton) and is home to our entire administrative, business development and engineering team. Morse Drive is also home to “Automation Lane”. This encompasses new technologies in automated insert molding as well as automated tray packing of highly engineered components.

Get in touch

Address

Rosti Midwest | N116 W18271 Morse Drive | Germantown, Wi 53022