The tendency for North American manufacturers of plastic parts to outsource tasks to South America or overseas is changing back toward reshoring – or that of keeping production processes in house and within the United States. After decades of offshoring for economic purposes, wages in emerging economies have started to rise substantially.

Category: Blogs

Key Qualities of High-Heat and Exotic Resins

Resin materials used in plastic injection molding have evolved significantly in recent years as advancements to combining plastics with fillers and reinforcement materials has become more common in many industrial applications to improve part performance and strength. In the past, plastics were not known to be highly heat resistant materials. It is becoming more known that there are now many high performance resins that can be put to use at temperatures up to 572 degrees Fahrenheit – depending on the part / product’s environmental factors and exposure to chemicals. High heat and exotic resins are particularly good metal replacement options because they provide incredible benefits in the areas of weight savings, chemical resistance, and sliding friction characteristics. Additionally, these great attributes can be maintained at high permanent operating temperatures.

Benefits of Dimensional Testing in Plastic Injection Moulding

A coordinate measuring machine (CMM) is a device that measures the physical geometrical characteristics of an object, and in our manufacturing application – plastic parts. The device is often used in manufacturing processes to qualify or test a part or against the design intent.

Preparing for Injection Moulding Resin Selection

Manufacturers use a wide variety of plastics to mold parts incorporated into products and have increasingly begun to replace other materials like bronze, stainless steel, aluminum, and ceramics. Some of the most popular reasons for using or switching to plastic include longer overall lifespan of the part, reduced wear on other components of a product, faster production line speeds, corrosion resistance and weight reduction. In addition, companies report an average 25-50 percent cost savings when parts are converted to plastic which oftentimes exhibit superior performance attributes.

6 Considerations When Choosing A Plastic Injection Moulder

With over 5,500 plastic injection-molding companies in the United States, product manufacturers are challenged with choosing the best partner to help mass produce a product or production element for a business. When you need thousands of parts produced on-time and under budget, having the peace of mind that your injection molder will truly be a partner, and keep your needs in mind, can make all the difference in the world when it comes to getting your product to market faster.

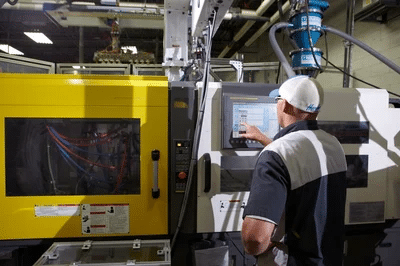

How RJG eDart Transformed PCI’s Injection Moulding Operation

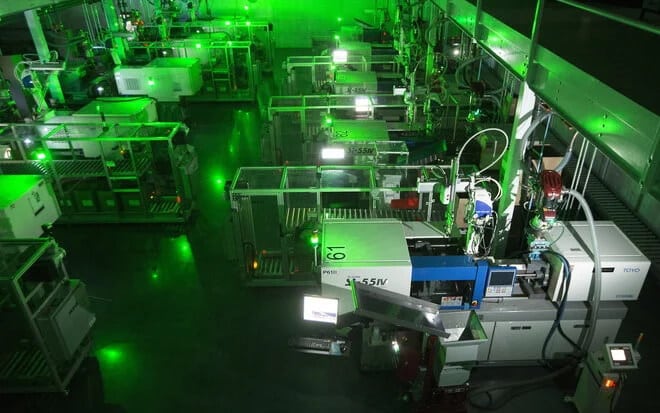

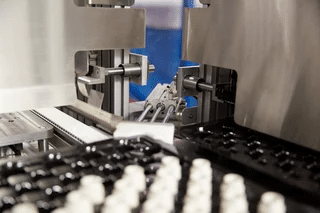

Injection molding technology has evolved greatly since the Hyatt brothers patented the first injection molding machine in 1872. Their initial plunger design was improved upon in 1946 when James Hendry created the first auger injection molding machine. But it wasn’t until the computer age when advances to the injection molding process started to take shape. Today’s plastic injection molders must stay at the forefront with scientific molding principles and processes to meet the demands of quality, consistency, efficiency, production, and cost savings.

Advantages of Scientific Moulding Practices

Scientific molding practices are essential to achieving outcomes that deliver faster cycles, higher volumes, and a more efficient injection molding process. Implementing sound scientific principles can help with determining optimal molding conditions. Equipment and software that help monitor real-time production processes guide the scientific molding stages and provide a critical advantage. In addition, quality control issues can be avoided by having automated containment control and traceability for specific applications. From collecting data to machine maintenance, process development to resin characteristics, and much more – scientific molding helps identify efficiencies which result in greater value and better parts for customers.

How to Implement an Efficient Injection Moulding Tool Transfer

Injection mould tool transfers require organized and upfront planning, communications, and investment to ensure all project goals and expectations are achieved.

Design Tips for Injection Molding with High-Heat or Exotic Resins

Throughout the injection molding process, there are several factors that affect efficiencies and viability of a plastic part. Before production begins, there are important design elements to consider – particularly when a part requires the use of a high heat or exotic resins.

Plastic Residence Time: Calculation and Process

From the specific plastic you are using, your mold, temperature, material density, and the machine itself and its individual parts, there are a number of variables that can make or break the injection molding process. One thing is certain: Processing too long or too short outside of the recommended plastic residence time can cause significant quality issues. Worse yet, not all resulting problems are immediately visible – inconsistency in melt quality, color variation, or weakened parts.