At a time when the global economy is facing a plethora of challenges, Jonas Persson wanted to share an insight into how Rosti Group are supporting our customers to navigate choppy waters. Also, it is important to highlight the measures and changes we have implemented internally, primarily utilising our technical, engineering, production, and sourcing expertise to be a true Global Partner to our current and prospective customers.

Category: Blogs

Spotlight on Rosti Uk

Comprising 8000m2 production and warehousing space, the Rosti UK site is based in Stamford Bridge, York. Providing plastic injection moulding solutions for the consumer goods, filtration, electrical, brewing and packaging markets, the site has a strong team of experts and a commitment to precision and performance.

What are the benefits of reshoring injection moulding production to the UK?

In recent months, we have seen an increase in the appetite for global companies to reshore production of injection moulded products and parts to the UK. This is also a trend we are seeing with global customers who want to localise their production and assembly near to their customer base.

Jonas Persson shares insight into Sustainability & future of Injection Moulding

Jonas Persson, Rosti CEO, shared his thoughts and observations on the future of injection moulding and how sustainability is now a fundamental element of their business strategy.

A positive outlook on the global Plastic Injection Moulding market – Jonas Persson, Rosti Group CEO

Despite the challenging economic conditions around the world, from high energy costs, a possible recession and rising inflation, I am proud that our solid foundation, combined with cutting-edge technologies and plastic injection moulding capabilities, provide a safe and reliable pair of hands for everyone.

Rosti’s 6 R’s of Sustainability

Our Sustainability Framework sets out the role and responsibility of each individual within the business, using the Rosti 6R’s to make “greener” choices from Concept to Reality.

Plastics And Positive Impact On Environmental Sustainability? Yes.

The plastics industry has played a key role in making modern life sustainable through affordable and accessible healthcare, food for all, and other conveniences. It now needs to act decisively to invest in innovation and technology aimed at increasing the lifecycle of its products for a sustainable tomorrow.

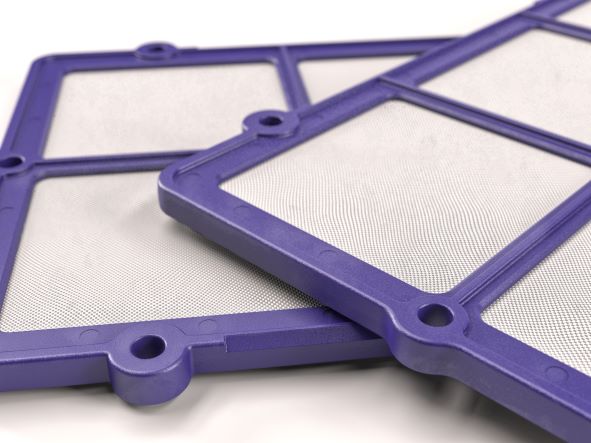

Why choose injection moulding for your Air and Water filtration products?

The modern filter has become a vital element in ensuring optimum performance of appliances and devices across both air and fluid management industries.

Producing Smart Devices for Cosmetics Industry

The call for personalised products and smart devices is getting louder – also in the cosmetics industry. This is not only about the cosmetic formulations that are applied to the skin, but about devices to help analyse, compose, and formulate individualised products. Patrick Williams knows the market and what the devices need to be able to do, he share his thoughts with COSSMA.

Rosti and Demag team up for innovation

Some business relationships are both longer and stronger than others. One such enduring partnership is between plastic injection moulder Rosti China and machine manufacturer Demag Sumitomo Plastics Machinery. Demag has been a partner with Rosti for over 35 years and during the last 17 years has delivered more than 100 machines to Rosti China.