In a testament to mentorship and dedication, Rosti GP proudly announces the successful certification of two Green Belt projects within the Rosti Lean Sigma standard. Under the guidance of our Site Black Belt Champion, Murat Haxha, our talented team members, Ismir Adrovic and Ömer Karpuz, have achieved outstanding cost and efficiency savings.

Category: News

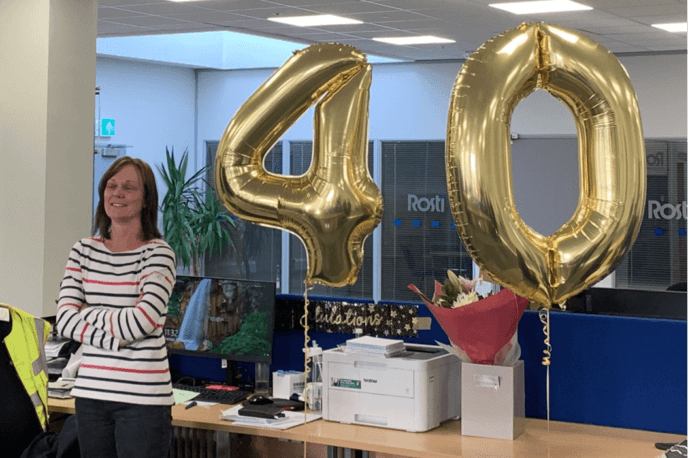

Alex Britland Celebrates 40 Years with Rosti UK

28th November saw Rosti UK celebrate 40 years of hard work and dedication from someone truly awesome here at Rosti UK, Alex Britland, Supply Chain Leader. As we reflect on four decades of commitment, hard work, and innovation, it’s clear that Alex has not just been a part of our organization; she has been an integral force shaping the very essence of who we are. In an era where loyalty to a single workplace is increasingly rare, Alex stands as a beacon of steadfastness, demonstrating that true dedication is a rare and invaluable trait.

Rosti: Bringing Excellent Services for Sustainable Growth of the Automotive Industry

Plastics play an important role in automotive manufacturing. With the gradual popularization of energy conservation and emission reduction in automobiles, the lightweighting trend of replacing metal with plastic in automotive parts has become one of the most effective measures to reduce automotive emissions and improve combustion efficiency. In this aspect, injection moulding technology can also realise the integrated manufacturing of automotive parts, thereby improving the production efficiency in the automotive sector.

Celebrating World Quality Day at Rosti Poland

On World Quality Day, Rosti Poland were proud to highlight our commitment to quality excellence in everything that we do. This year, our team have engaged in a number of activities that not only celebrate quality but also underline its central role in our daily work.

Rosti Utah Managing Director, Lukasz Sekula reflects on his move from Rosti Poland

Newly appointed Rosti Utah Managing Director, Lukasz Sekula shares his career journey since joining Rosti Poland as a Quality and Systems Manager in 2018, culminating with moving across to North America as part of our senior management team. Following the integration of Rosti North America into the wider Rosti Group, Lukasz spent a period of time at our Utah facility towards the end of 2022, supporting the team in implementing operational improvements across the production facility.

Rosti Germany GmbH celebrates 20th Anniversary

Rosti Germany GmbH is delighted to celebrate 20 years since it was founded under the name GP PLASTINDUSTRI in September 2003. Our production facility in Dresden has continuously grown throughout the two decades, producing up to 4 billion closures for the packaging industry with over 40 injection moulding machines and a team of 80 colleagues.

Rosti North America Opens Digital Innovation Lab to Support Global Injection Moulding Services

Rosti North America’s new Digital Innovation Lab in North America is helping to revolutionise rapid prototyping with its accelerated concept-to-reality process in just 72 hours. Rosti North America announced today the grand opening of its state-of-the-art Digital Innovation Lab in North America, located in the company’s Germantown, WI manufacturing facility on Bunsen Drive.

Rosti – Your Dependable Plastic Injection Moulding Partner and Contract Manufacturer

A business you can rely on to continuously deliver the highest-quality product, engineering and service, focusing long-term collaborative partnerships. Our conservative financial approach ensures we will always be a dependable partner to our customers and enables us to operate from a position of stability. This approach continues to this day, with our secure position being bolstered by our relationship with our owner Nordstjernan, a Swedish family-controlled investment company.

Rosti’s Tony Austin to Address Reshoring and Contract Manufacturing at Interplas 2023

Reshoring and contract manufacturing roundtable session will include a thought-leader debate on what lies ahead for the industry. European Business Development Technical Director Tony Austin will take the stage during Interplas 2023 on September 26 from 14.00 – 14.45pm at the NEC in Birmingham, United Kindom.

How can Rosti contribute to accelerating time to market in the consumer electronics market?

You think the facial cleanser just needs its cleaning function? Nowadays, consumer electronics devices also connect to mobile apps through wireless networks, helping users record the frequency and level of daily cleaning, and even achieving social functions to share usage experiences. Of course, similar functions have been common in consumer appliances such as Sous-vide and intelligent rice cooker.