As a leading precision plastic injection moulding business, Rosti knows that quality is non-negotiable — for us and for our customers. But our commitment goes far beyond delivering high-performance plastic components. It’s about delivering them with accountability, transparency, and industry-verified compliance.

Tag: Certifications

Rosti UK Achieves ISO 50001 Certification

Rosti UK is proud to announce its successful completion of the Stage 2 audit for ISO 50001 certification, a testament to our commitment to sustainable energy management.

Introducing Inside Rosti Medical Solutions

Discover our vision for advancing medical manufacturing through innovative solutions and precision engineering. We highlight our commitment to sustainability with Carbon Additive Manufacturing, showcasing eco-friendly practices and cutting-edge technology. Meet our dedicated medical team, whose expertise and passion drive our success. Join us as we embark on a journey to revolutionize medical moulding and contribute to a healthier, more sustainable future.

Rosti Poland Achieves ISO 50001 Certification

We are proud to announce that Rosti Poland has been awarded the ISO 50001 certification, confirming our commitment to sustainable energy management across our plastic injection moulding operations.

How do Rosti support customers with material selection?

Rosti has a deep knowledge and experience in using an array of materials that comply with stringent sector and international regulatory and compliance standards.

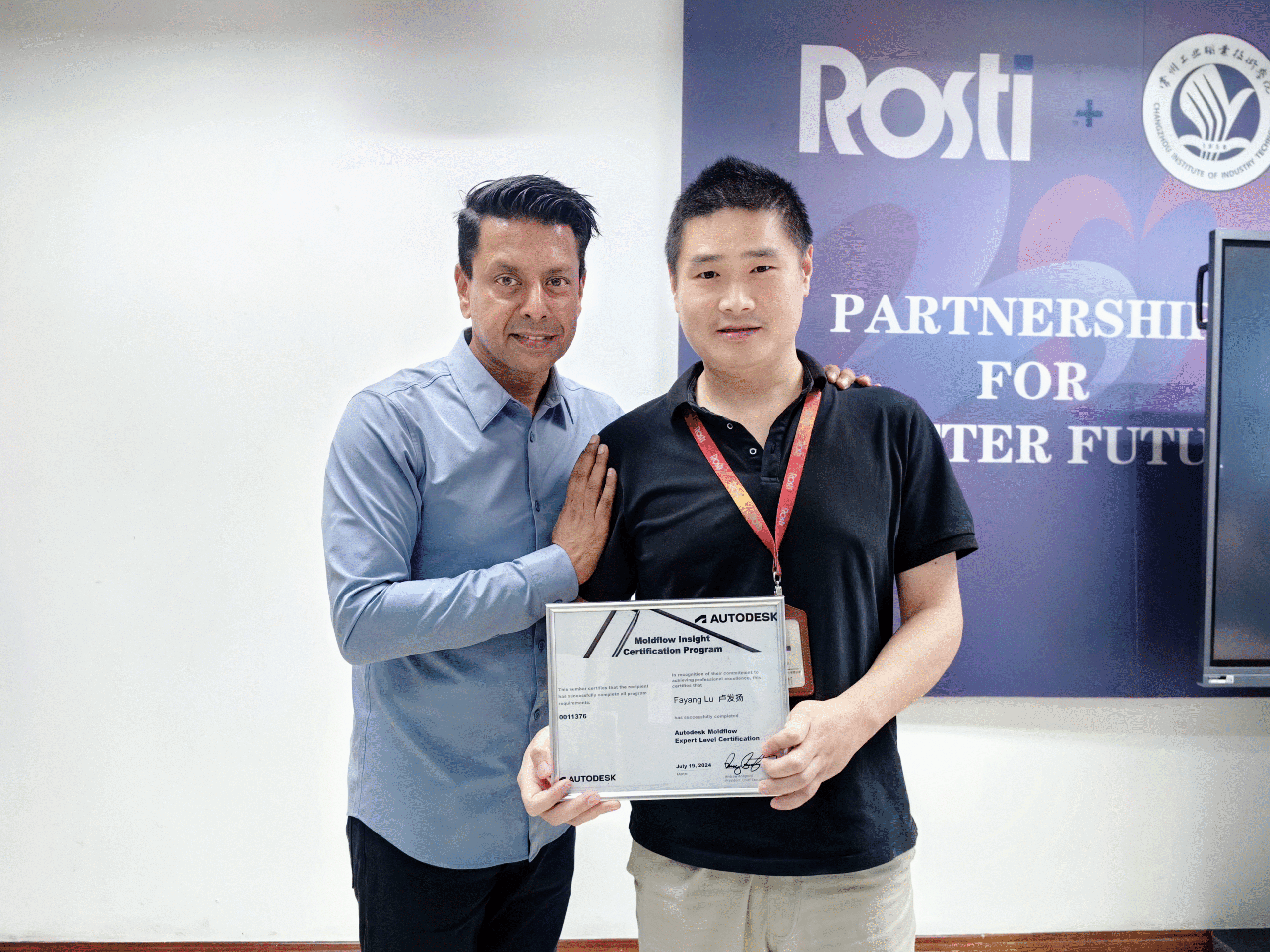

Devin Lu awarded Autodesk Moldflow Expert Certification

We are proud to announce that one of our employees Devin Lu, the Design Analysis Supervisor has successfully achieved the prestigious Moldflow Expert Level Certification, one of the 50 persons in China achieved this honor.

Realise the Benefits of Carbon Digital Light Synthesis technology for Medical Contract Manufacturing

In the dynamic landscape of medical and pharmaceutical contract manufacturing, continuous investment in innovation is essential for delivering cutting-edge solutions that enhance patient care.

A global vision for medical moulding – Medical Device Developments

Karl Stillman, Vice President, Strategic Sales, Rosti Group, explains to Medical Device Developments how technological capability and manufacturing knowhow must go hand in hand with management capability and years of experience to fully satisfy the industry’s requirements.

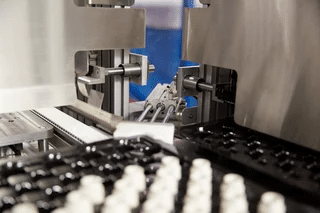

High-precision injection moulding is essential to the manufacture of many medical devices, but technology alone cannot meet the stringent quality levels demanded by today’s life sciences sector.

Rosti Group to Showcase Medical Expertise at MedtecLive 2024 – Stand 1-238

Rosti Group’s Medical Solutions, a manufacturing business with ISO 13485 accredited facilities around the globe, are set to exhibit our cutting-edge capabilities at MedtecLIVE 2024, taking place from June 18 to 20 in Stuttgart.

6 Considerations When Choosing A Plastic Injection Moulder

With over 5,500 plastic injection-molding companies in the United States, product manufacturers are challenged with choosing the best partner to help mass produce a product or production element for a business. When you need thousands of parts produced on-time and under budget, having the peace of mind that your injection molder will truly be a partner, and keep your needs in mind, can make all the difference in the world when it comes to getting your product to market faster.