With over 5,500 plastic injection-molding companies in the United States, product manufacturers are challenged with choosing the best partner to help mass produce a product or production element for a business. When you need thousands of parts produced on-time and under budget, having the peace of mind that your injection molder will truly be a partner, and keep your needs in mind, can make all the difference in the world when it comes to getting your product to market faster.

Tag: Plastic Injection Moulding

How RJG eDart Transformed PCI’s Injection Moulding Operation

Injection molding technology has evolved greatly since the Hyatt brothers patented the first injection molding machine in 1872. Their initial plunger design was improved upon in 1946 when James Hendry created the first auger injection molding machine. But it wasn’t until the computer age when advances to the injection molding process started to take shape. Today’s plastic injection molders must stay at the forefront with scientific molding principles and processes to meet the demands of quality, consistency, efficiency, production, and cost savings.

Plastic Components, Inc. Purchases Additional Facility -Video Sneak Peak!

As part of Plastic Components, Inc.’s fully automated production strategy, the company recently invested in the purchase of a new 15,000 square foot facility located on Bunsen Drive in Germantown, WI to support the company’s growth from its existing customer base and new market opportunities. The company investment included the purchase of a new building, remodeling and new equipment; which will allow PCI to remain efficient and globally competitive.

A New 400 Ton Press Has ArrivedI

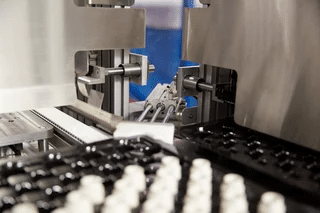

Plastic Components, Inc. is proud to announce the arrival and implementation of a new 400 Ton Toyo Injection Molding machine. This is the second 400 Ton press within the facility. A is the standard at Plastic Components, the press will be part of a fully automated manufacturing cell. This is the fundamental premise behind the manufacturing strategy at PCI. Using state of the art robotics and conveyors, we are able to sell components to our customers with no direct labor. This allows PCI to produce defect free parts at globally competitive pricing.

Plastic Components, Inc., of Germantown, WI Breaks Ground On 23,000 Square Foot Expansion For “Lights-Out” Manufacturing Facility

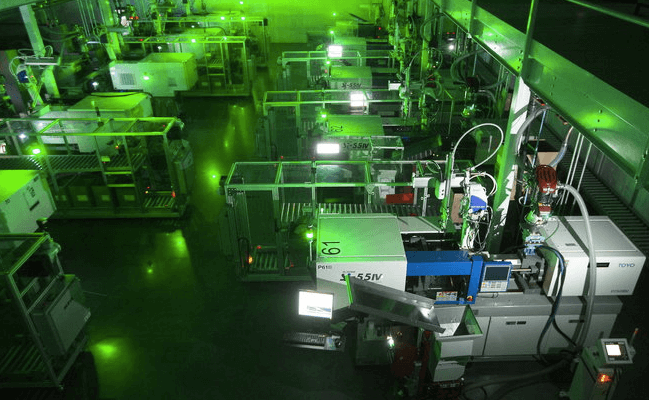

More than doubling the space for the company’s state-of-the-art injection molding systems, Plastic Components, Inc. will reinforce their position among international competitors with medium and high-quantity production of defect-free parts in their revolutionary “lights-out” facility.

Plastics News Feature: Parts Makers at this Custom Injection Molder Don’t Mind the Dark

There are no machine operators employed at Plastic Components Inc., a custom injection molder with two facilities in Germantown, Wis. Most of the time, the “parts makers” at the company’s roughly 38,000-square-foot facility on Bunsen Drive don’t require physical supervision and really don’t seem to mind whether the lights at the factory are turned on or off.

Plastics News Feature: Plastic Components Enters M&A Game with First Acquisition

Plastic Components, Inc.’s CEO, Derrill Rice, talked with Audrey LaForest of Plastics News about the company’s recent acquisition of Syracuse Plastics of North Carolina Inc. – a regional manufacturer of engineered and high precision injection molded components for applications in the industrial, water and pool products, telecommunications, power products, food processing, and other end markets.

PCI Recognized with 2019 MAPP Innovation Award

Future success for many injection molders is dependant on the company’s ability to find efficiencies and innovative ways to improve business processes. Even small improvements can add up to big increases in productivity. Each year, the Manufacturers Association for Plastics Processors (MAPP) celebrates the innovative practices of a select handful of companies that touch on all areas of plastics manufacturing.

PCI Supports Milwaukee River Keeper’s Adopt-a-River Program

Milwaukee Riverkeeper® is an organization dedicated to protecting, improving, and advocating for water quality, riparian wildlife habitat, and sound land management in the Milwaukee, Menomonee, and Kinnickinnic River Watersheds.

E-mobility Guide

Rosti works with some of the world’s leading producers to face up to the manufacturing challenges in e-mobility. This is a sector with rapid growth – driven by environmental pressures and government legislation – and we are helping to facilitate the leap from prototype manufacturing to mass production.