From the specific plastic you are using, your mold, temperature, material density, and the machine itself and its individual parts, there are a number of variables that can make or break the injection molding process.

One thing is certain: Processing too long or too short outside of the recommended plastic residence time can cause significant quality issues. Worse yet, not all resulting problems are immediately visible – inconsistency in melt quality, color variation, or weakened parts.

Taking the time to calculate the specific plastic residence time for the relevant manufacturing process will improve your material performance and the overall final product.

Plastic residence time is the time that plastic or resin is subjected to heat during fabrication.

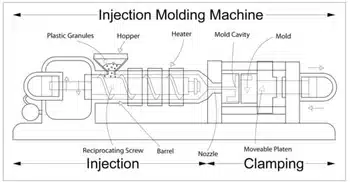

An injection system features a hopper, barrel, reciprocating screw, and injection nozzle. The shot size is the maximum amount of plastic injection mold that can be injected in one molding cycle. Pellets are fed through the hopper into the barrel and screw assembly. The barrel supports the reciprocating screw where the material is then melted through conduction from the electric resistance heater bands surrounding the barrel. The reciprocating screw compresses, melts, and meters the material.

The size of the shot and barrel impact the length of residence times, which can in turn, affect the quality of the product. Small shot sizes that use minimal barrel capacity can result in long residence times and polymer degradation. On the other hand, large shot sizes and more than 50% of barrel capacity can result in poor melt uniformity and long screw-recovery.

Material is quickly affected by the length of time and exposure temperature. Some polymers, according to the Injection Molding Handbook, are “hydrolytically degradable and may suffer undesirable depolymerization effects due to chemical reaction of moisture with the polymer prior to devolatilization.”

Understanding the residence time of material in the first stage of the screw can help you understand the optimal time and temperature for your manufacturing needs.

Plastic residence time affects part quality in several different ways:

- General weakness in parts produced

- Color variation

- Degradation not visible to the eye

- An overall compromised product

However, it can also impact machine performance, result in inconsistency in the melt quality and shot weight, as well as the melt temperature.

Before calculating residence time, it’s important to understand the different components involved.

The difference between residence time and shot size

Shot size is the amount of resin that needs to be injected into the mold. Residence time is based on the shot size, barrel size, and the screw inventories in the channels.

The screw serves multiple functions. It moves the material through the barrel, mixes the material, compresses it to its maximum density, and moves the material into the mold. The size and design of the screw impact the space available to the plastic inside the barrel. It’s not uncommon for manufacturers to have more than one screw and barrel option.

As you review different formulas and advice to find your own residence time calculation for a new machine or a mold that hasn’t yet been built, you may want to start with a mold analysis first.

Calculations

There are a few different approaches to calculating plastic residence time. Here are two different options to give you a better idea of the factors involved.

Calculation #1:

Barrel size = 3.14 x (Barrel radius)^2 x (Barrel length)

Screw size = 3.14 x (Average root radius of the screw)^2 x (Barrel length)

Volume of the shot = Barrel volume (minus) screw volume

Plastic residence time then equals the number of shots multiplied by your cycle time.

Calculation #2

Shot capacity (divided by) 1.05 x Material density at room temperature = Inventory

Plastic residence time = Inventory (divided by) shot size x cycle time / 60

Hot tips

- Keep in mind melt densities. You’ll want to run calculations of the material weight at a solid-state and its molten state.

- Start with a clean, uncontaminated barrel.

- The recommended barrel capacity is between 25% and 65% plus an additional 10% for safety.

- If you can, use volume and melt densities instead of weight.

Take the Time to Make the Calculations

No matter how many shared formulas or calculations, plastic residence time should be calculated by each individual manufacturer in order to determine the ratio that works for their particular product.

Using scientific molding practices, Rosti uses recorded data to assess quality control and make any needed tweaks to tooling, thus improving overall part quality and avoiding the negative effects of poorly calculated plastic residence time.

Rosti has the most advanced technology and equipment, along with the technical expertise and experience to successfully produce the highest quality plastic parts for your unique application. Learn how Rosti goes above and beyond to be a supplier you can trust.