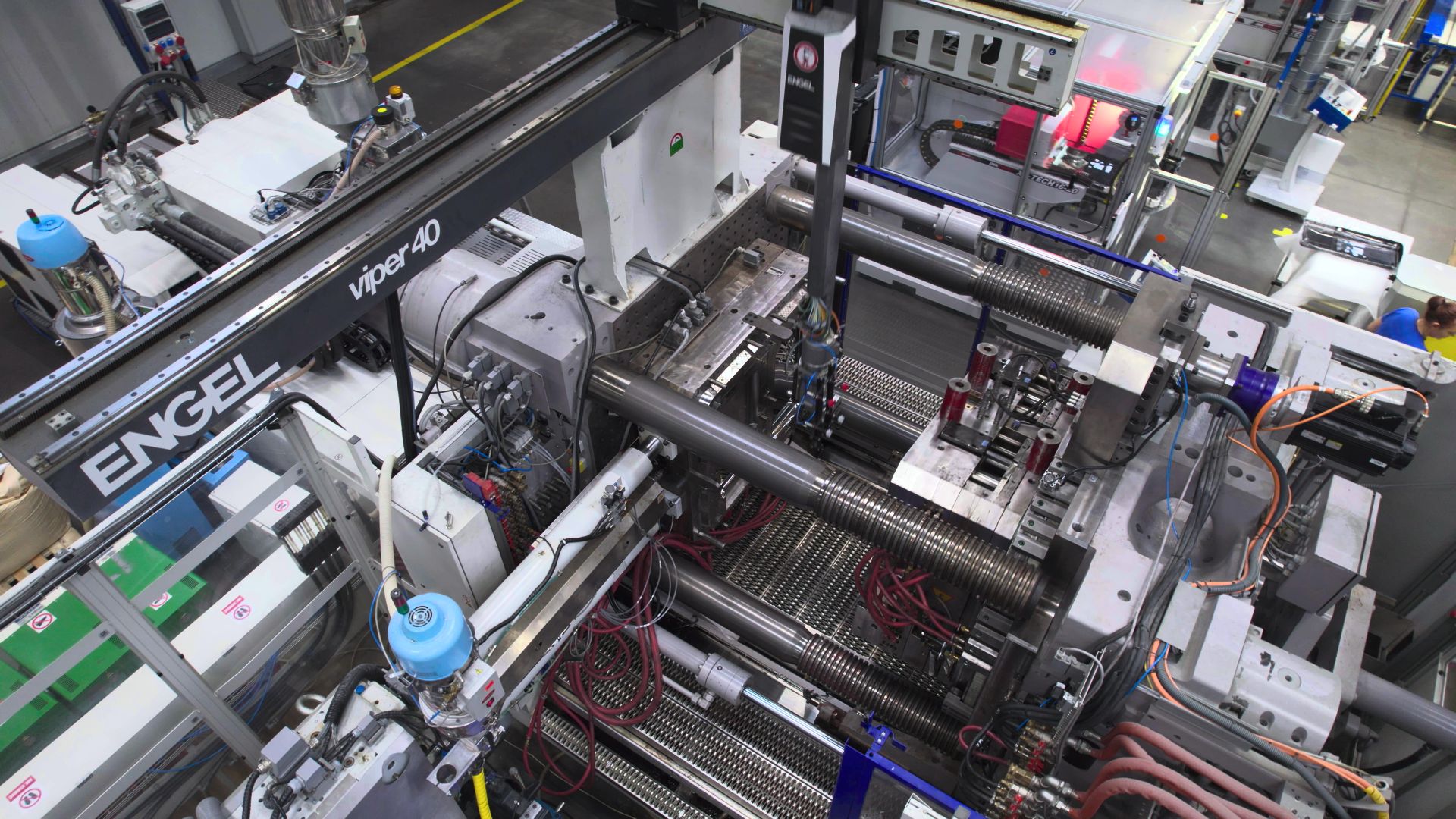

In a rapidly evolving world, where technology and materials science merge seamlessly, injection moulding of smart plastic components with embedded electronics is a game-changer. These innovative components combine the durability of plastic with advanced electronics, creating products that are lightweight, functional, and versatile.

Tag: Design Support

Introducing our latest Inside Rosti

As we wrap up another remarkable year, we’re excited to share the latest updates in our end-of-year newsletter.

Supporting the Medical Industry in Limiting Time-to-Market through Innovation Capabilities and 72-Hour Concept-to-Reality Process

In the fast-paced world of medical device manufacturing, time to market is a decisive factor for success. The ability to design, manufacture, and deliver new medical devices at speed is crucial from the perspective of having an impact on patients, meeting regulatory requirements and the commercial success of a device.

Rosti Group’s Partnership with Global Energy Storage Leader in E-Mobility Solutions for Large Vehicles

In 2017, Rosti Group embarked on a strategic partnership with a German energy storage company focused on advancing e-mobility solutions for large vehicles such as buses, coaches, and heavy goods vehicles (HGVs).

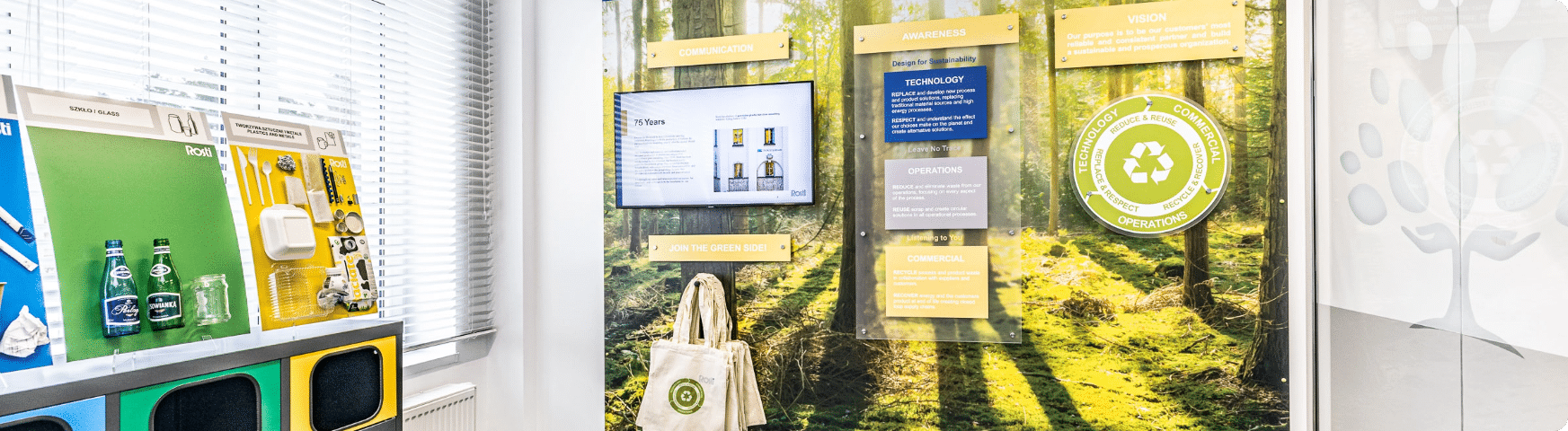

Rosti Group’s Collaboration with Position Green to Measure and Reduce Carbon Footprint

Earlier this year, Rosti Group took a significant step on our sustainability journey by partnering with Position Green, ESG experts, and carbon platform providers. Our initial work has been to accurately measure our carbon footprint, collecting essential data, forming a comprehensive baseline that will guide our Site Champions in minimising our environmental impact.

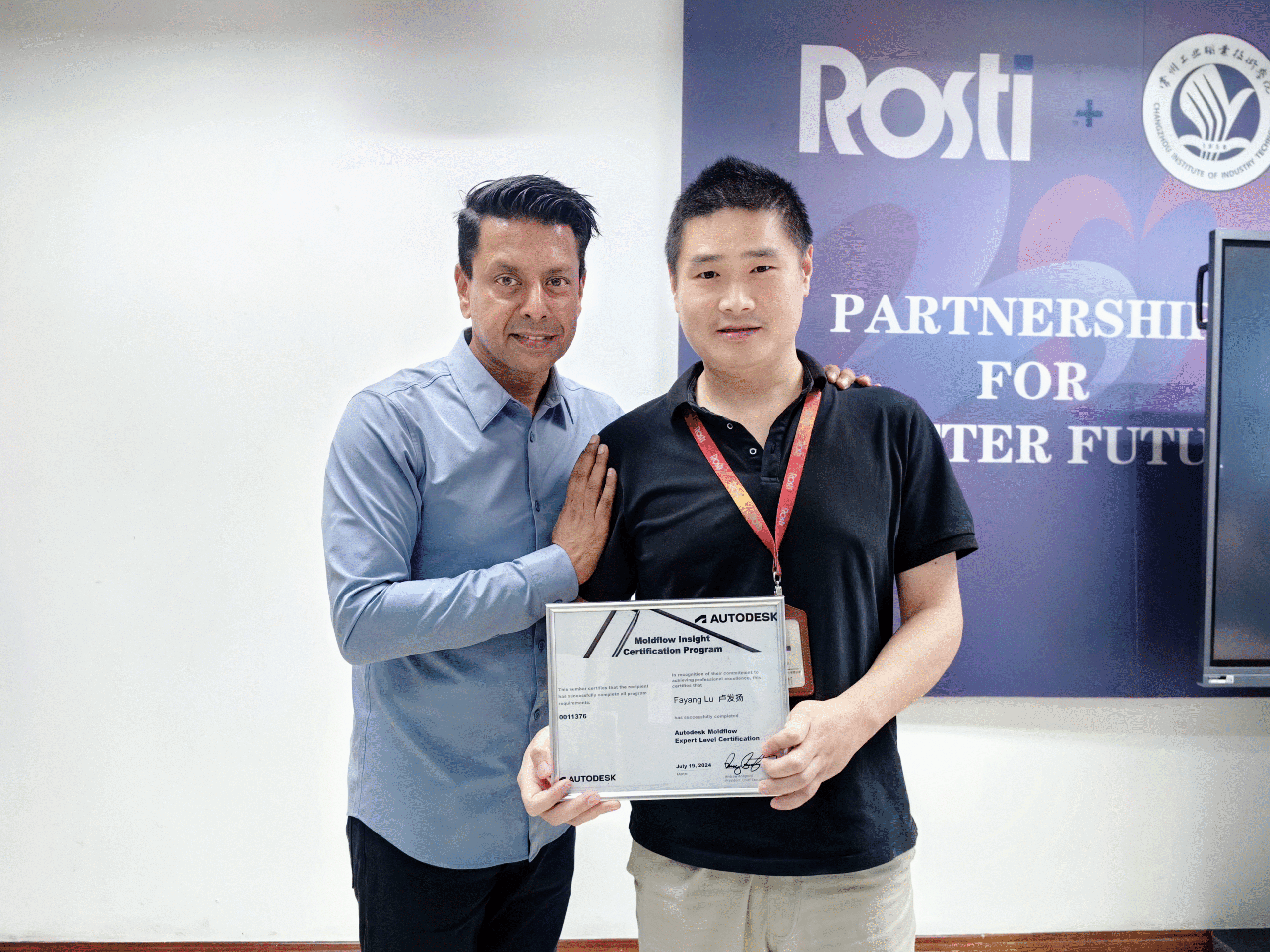

Devin Lu awarded Autodesk Moldflow Expert Certification

We are proud to announce that one of our employees Devin Lu, the Design Analysis Supervisor has successfully achieved the prestigious Moldflow Expert Level Certification, one of the 50 persons in China achieved this honor.

Rosti Group to Showcase Advanced Medical Solutions Manufacturing Capabilities at MedtecLIVE 2024

Rosti’s MedtecLIVE 2024 exhibit will showcase next-generation medical manufacturing featuring advanced prototyping, custom manufacturing solutions, industry-leading design collaborations, cutting-edge carbon technology, and more.

Rosti Showcases Breakthroughs in Medical Innovation at 2024 Innovative Plastics Materials Application & Processing Technology Congress

At a recent industry-leading event, Ke Rong, the esteemed Medical Solutions Operations & Quality Director of Rosti, unveiled the company’s strategic vision for revolutionizing medical product development. Emphasizing Rosti Group’s commitment to excellence in the medical sector, Ke Rong showcased our cutting-edge technologies and services, particularly highlighting our rapid prototyping capabilities.

Navigating Innovation: Role of the Rosti Technology Roadmap for Plastic Injection Moulding Capabilities

In the dynamic landscape of manufacturing, where innovation is the key to staying ahead, we understand the critical importance of investing in cutting-edge plastic injection moulding technologies.

3-D Printing Creates Efficiencies in Injection Molding

In the world of plastics manufacturing, there has been a definitive line between 3D printed parts and plastic injection molded parts. However, in recent years, that line has blurred as more injection molders not only see the value in 3D printing for prototyping parts or low-volume runs but also to help create efficiencies in their own manufacturing processes. While using 3D printing to improve injection molding outcomes is not always common practice, PCI’s forward-thinking engineers have identified areas where additive molding plays a significant role in enhancing machine functionality.