You think the facial cleanser just needs its cleaning function? Nowadays, consumer electronics devices also connect to mobile apps through wireless networks, helping users record the frequency and level of daily cleaning, and even achieving social functions to share usage experiences. Of course, similar functions have been common in consumer appliances such as Sous-vide and intelligent rice cooker.

Tag: Plastic Injection Moulding

What are the advantages of Multi-K injection moulding?

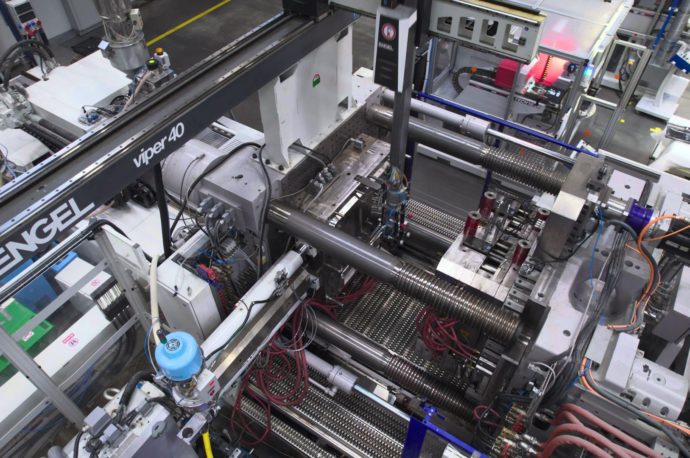

At Rosti Group, we have a wealth of knowledge and expertise in supporting our clients to realise the benefits of Multi-K injection moulding, across our global footprint of manufacturing facilities. We work closely with our customers to transition to Multi-K (multi-shot) injection moulding, including 2k, 3k and 4k moulds, combining multiple materials and finishes.

Rosti Group’s Sustainability Strategy – the right thing to do

Sustainability is no longer simply a topic that is only talked about in an aspirational way. Implementing measures that make a significant difference to the environment is now at the top of the global agenda. As a plastic injection moulding business, Rosti is responsible for ensuring our operations, behaviours and what we produce have little to no harmful impact on the environment.

3-D Printing Creates Efficiencies in Injection Molding

In the world of plastics manufacturing, there has been a definitive line between 3D printed parts and plastic injection molded parts. However, in recent years, that line has blurred as more injection molders not only see the value in 3D printing for prototyping parts or low-volume runs but also to help create efficiencies in their own manufacturing processes. While using 3D printing to improve injection molding outcomes is not always common practice, PCI’s forward-thinking engineers have identified areas where additive molding plays a significant role in enhancing machine functionality.

4 Reasons to Consider Metal to Plastic Conversion

Since the introduction of engineering-grade resins and plastic materials in the 1950s, many parts previously fabricated from metal have been replaced by injection molded parts. On average, companies report an overall cost savings of 25-50% by converting to plastic parts, yet some manufacturers have resisted making the change.

Design Is Top Consideration To Reduce Plastics Manufacturing Costs

Plastics manufacturing is a highly competitive, global industry in which businesses are presented with both time and cost challenges. Avoiding delays and reducing risks for costly design changes can mean that your product gets to market faster than your competitors. The sharp line that was once drawn between development and production is now, oftentimes, blurred with manufacturers leaning on industry design experts to become involved in the design for manufacturability process. In fact, manufacturers rank design as the top factor in reducing overall manufacturing costs.

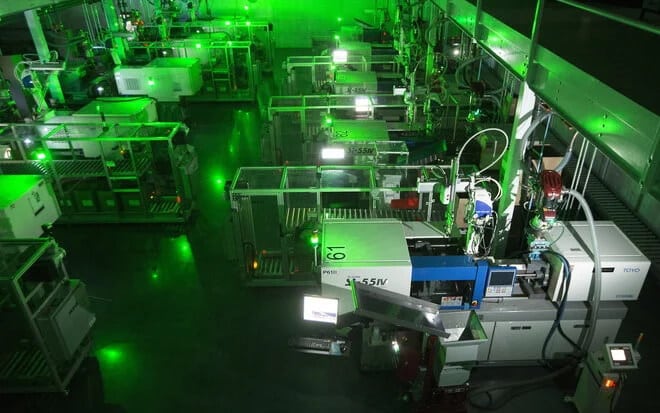

5 Ways Lights-Out Manufacturing Has Transformed Injection Moulding

The tendency for North American manufacturers of plastic parts to outsource tasks to South America or overseas is changing back toward reshoring – or that of keeping production processes in house and within the United States. After decades of offshoring for economic purposes, wages in emerging economies have started to rise substantially.

Key Qualities of High-Heat and Exotic Resins

Resin materials used in plastic injection molding have evolved significantly in recent years as advancements to combining plastics with fillers and reinforcement materials has become more common in many industrial applications to improve part performance and strength. In the past, plastics were not known to be highly heat resistant materials. It is becoming more known that there are now many high performance resins that can be put to use at temperatures up to 572 degrees Fahrenheit – depending on the part / product’s environmental factors and exposure to chemicals. High heat and exotic resins are particularly good metal replacement options because they provide incredible benefits in the areas of weight savings, chemical resistance, and sliding friction characteristics. Additionally, these great attributes can be maintained at high permanent operating temperatures.

Benefits of Dimensional Testing in Plastic Injection Moulding

A coordinate measuring machine (CMM) is a device that measures the physical geometrical characteristics of an object, and in our manufacturing application – plastic parts. The device is often used in manufacturing processes to qualify or test a part or against the design intent.

Preparing for Injection Moulding Resin Selection

Manufacturers use a wide variety of plastics to mold parts incorporated into products and have increasingly begun to replace other materials like bronze, stainless steel, aluminum, and ceramics. Some of the most popular reasons for using or switching to plastic include longer overall lifespan of the part, reduced wear on other components of a product, faster production line speeds, corrosion resistance and weight reduction. In addition, companies report an average 25-50 percent cost savings when parts are converted to plastic which oftentimes exhibit superior performance attributes.