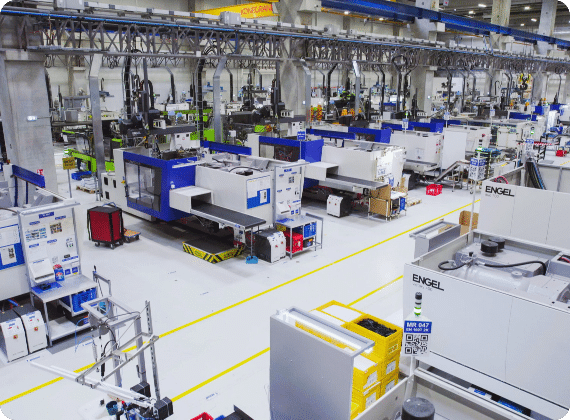

Looking for a plastic injection moulding partner in Turkey? At our 6,732m2 Istanbul facility, Rosti Turkey (formerly known as Rosti Tebplast) supplies top filled packaging and specialised in-mould labelling for some of the world’s leading brands in the cosmetic, dairy and frozen food markets. With a production capacity of 14,000 tons of raw materials, we are one of Turkey’s largest In-Mould Labelling (IML) manufacturers.

Rosti Turkey | Selimpaşa Merkez, Kavaklı Mahallesi, Kıble Sokak No:9 | Silivri/İstanbul | Türkiye

Rosti Turkey Legal Information (Rosti Türkiye Yasal Bilgiler)

Rosti Turkey

Download our catalogue

For more detail on our products and capabilities,

visit our catalogue here

Facts & Figures

6,732m² Facility

180 Employees

50 Plastic Injection moulding

machines

Certifications

Take a look at our industry specific certifications from approved bodies, to ensure we provide you with guaranteed service.

International Standard for Quality Management (2015 - latest version)

International Standard for Health & Safety Management (2018 - latest version)

International Standard for Environmental Management (2015 - latest version)

Brand Reputation Compliance Global Standard, a part of British Retail Consortium standards - Quality & safety standards in food manufacturing industry. Replaced BRC/IoP at version 6

International Standard for Food Safety Management (2018 - latest version)

Sharia Law food safety management system

Our Capabilities

Our plant has 50 machines, ranging from 150T-onwards, dedicated to total packaging solutions. With precision, performance, flexibility and care, Rosti Turkey provides injection moulding, assembly line production (form fill seal), In-Mould Decoration (IMD) and In-Mould Labelling (IML), all performed according to the BRC Global Standard for packaging materials and brand quality standards. These capabilities are well-suited for plastic packaging applications, most notably food packaging.

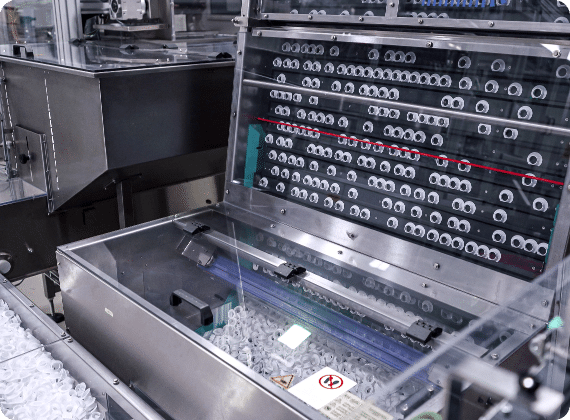

With a strong focus on precision and quality, Rosti utilises the latest in-mould labelling technology to produce superior products with a durable finish. Our Turkey location has state-of-the-art production equipment, cutting-edge technology, and a highly skilled workforce with extensive experience in IML. Rosti Turkey’s innovative In-mould labelling technologies are one of its differentiating factors and one of the reasons we export products to 36 countries and counting.

Our services

Rosti Turkey delivers a complete range of services dedicated to packaging; from R&D, design and project management, to tooling management and logistics.

Get in touch

Address

Rosti Turkey

Selimpaşa Merkez, Kavaklı Mahallesi, Kıble Sokak No:9,

Silivri/İstanbul

Türkiye