As industries demand smarter, smaller, and more efficient products, the integration of electronics directly into plastic components has become a game-changing innovation.

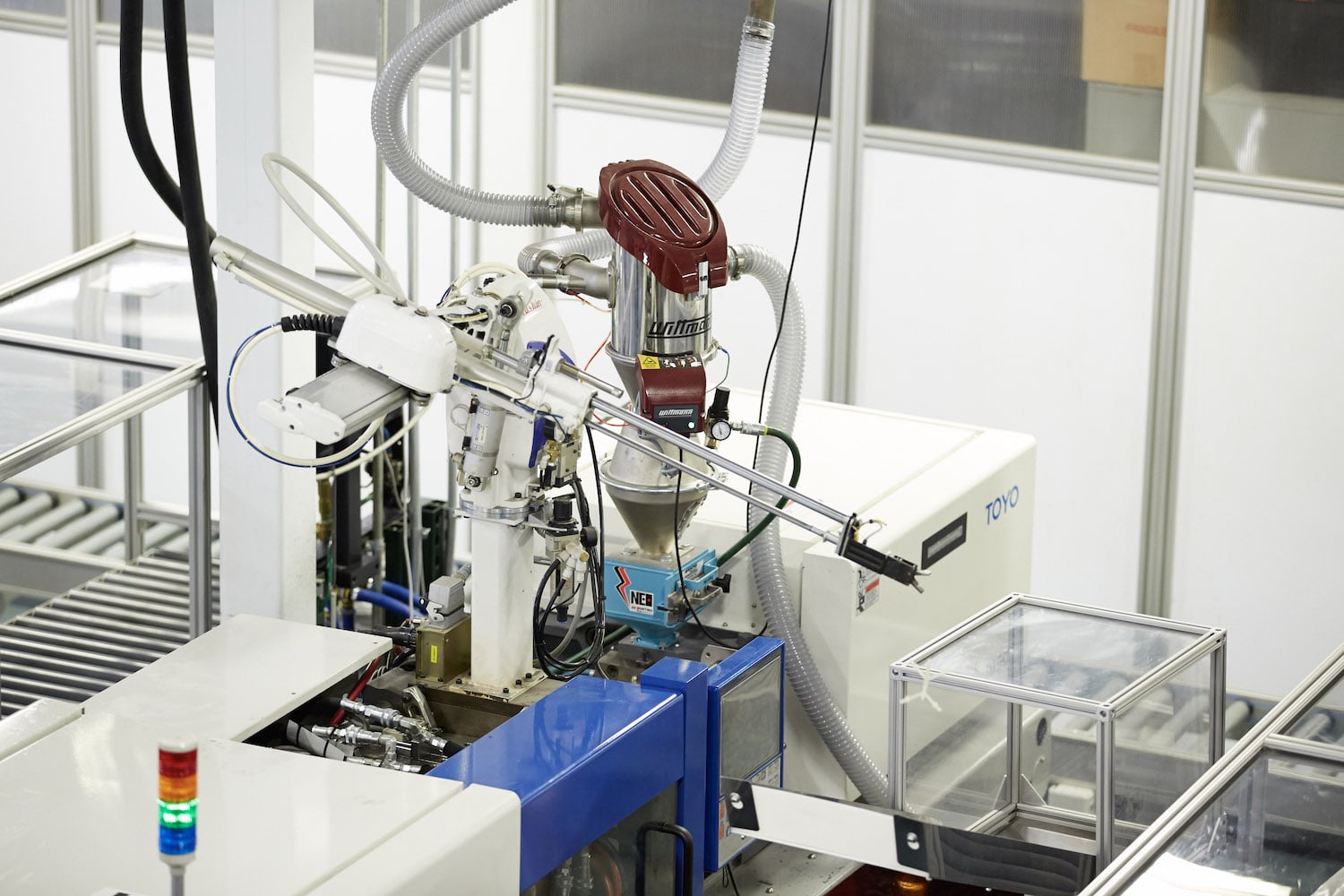

By embedding functionality during the plastic injection moulding process, you can create durable, compact, and multifunctional parts that meet the expectations of modern product design.

What are Smart Plastic components?

Smart plastic components integrate electronic functionalities such as sensing, communication, or control, directly into the structure of a moulded part or product. Unlike traditional assemblies that rely on printed circuit board assemblies (PCBAs), these solutions incorporate the electronics during the moulding process itself.

This approach enables greater design freedom, improved performance, and simplified production. Smart plastics are increasingly used across automotive, consumer electronics, industrial equipment, and medical devices, enabling new levels of efficiency and capability.

Benefits of Embedded Electronics

Reduced reliance on traditional PCBA

Traditional electronic assemblies rely heavily on printed circuit boards, connectors, wiring, and additional housings. These separate parts increase weight, cost, and complexity.

By embedding electronics directly into the moulded plastic, you can dramatically simplify the overall architecture of a product. This eliminates the need for standalone circuit boards, reduces assembly processes, and lowers production costs. With fewer components to manage and integrate, products become more robust, streamlined, and reliable.

Streamlined product designs

Miniaturisation continues to drive innovation across many sectors, and embedded electronics play a crucial role in enabling smaller and more space-efficient designs. Without the constraints of traditional PCBA layouts, designers are free to create thinner, lighter components that deliver the same or greater levels of performance.

In consumer electronics, this results in clean, modern devices that appeal to customers. In industrial or automotive settings, it enables more compact systems with smarter, more integrated controls. The overall effect is greater design freedom paired with manufacturing efficiency.

Integration of advanced functionality

Smart plastics make it possible to integrate touch sensors, antennas, lighting elements, control panels, and other advanced features directly into the component’s surface or structure. This creates intuitive, seamless interfaces without the need for additional buttons, modules, or external controls.

End users benefit from cleaner aesthetics and improved usability, while brands gain a valuable opportunity to differentiate products with innovative features that are often simpler and more cost-effective to produce than traditional electronic assemblies.

Lower bill of materials and cost savings

By eliminating removing the need to a number of individual parts, embedding electronics directly into the moulded part significantly reduces the bill of materials. This consolidation simplifies the supply chain and procurement process, ensuring that fewer components need to be sourced, stocked, and assembled.

The result is a more efficient, streamlined production workflow that speeds up time-to-market and reduces labour costs. This all helps to reduce the overall production costs of your product or component.

Improved durability and performance

Encapsulating electronics within moulded plastic offers enhanced protection against moisture, vibration, dust, and mechanical shock. This ensures that products maintain their performance even in challenging environments when used on a vehicle, a medical device or even used outdoor. Increased durability leads to longer product lifecycles, fewer returns or failures, and reduced need for replacements, which not only improve customer experience and reduced cost but also reduces the impact on the environment.

Shaping the future of product innovation

Smart plastic components with embedded electronics represent a major step forward in product design and manufacturing. By reducing reliance on traditional PCBA, enabling compact and streamlined designs, unlocking advanced functionality, and providing both cost and durability advantages, these solutions offer you a powerful route to innovation.

As demand grows for smaller, smarter, and more integrated solutions, embedded electronics are no longer a future possibility – they are becoming an essential part of modern product development.

Contact Rosti to explore how smart plastic components can transform your product design.