The modern filter has become a vital element in ensuring optimum performance of appliances and devices across both air and fluid management industries.

There are several factors driving the rapid development in the filtration industry, not least environmental pressures on the quality of the air we breathe and water we drink. Together with the changes, we see in the environments we live in; filtration products are becoming part of our everyday life. As a result, the design of filtration products is getting more and more technically complicated as their performance and mass production volumes increase.

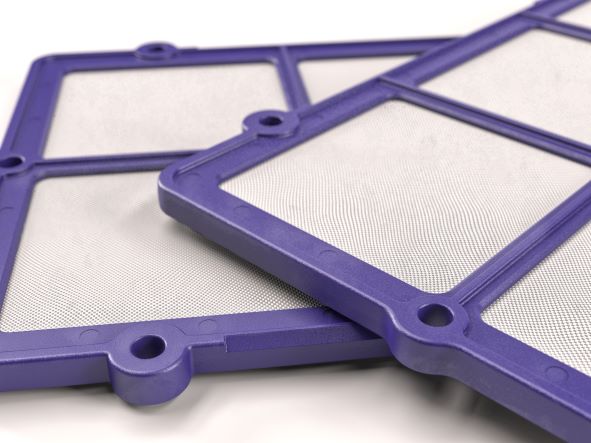

Injection moulding offers the perfect solution for creating a structure for filter media products of all shapes and sizes.

Rosti activity in the filtration market stretches back many years, working with some of the world’s leading OEMs Rosti use proven production techniques to meet current manufacturing challenges head on. One such challenge involves the mass production of various consumable HEPA air filters for one of the world’s largest domestic appliances manufactures using multi-shot moulding of various contrasting materials and over moulding permeable membranes using automated cell manufacturing.

Utilising Rosti’s 77 years’ experience in the injection moulding industry across all markets has enabled us to offer our customers engineering and design solutions that have maybe not have been considered before. This has resulted in a quality product being produced in large volumes via a fully automated process in a very cost-effective way, something our customers thought was not possible.

Injection Moulding Capabilities

Rosti has for years been challenged by customers– across multiple markets – to design complex moulds with numerous in-mould features, an expertise that would almost certainly be required for filtration product applications.

Utilising in-house, state-of-the-art mould-flow simulation and production software, Rosti is able to take ideas from concept to reality.