We sit down with Gustav Reingsdahl to explore the evolving global medical injection moulding market and the strategic role Rosti plays as a trusted contract manufacturing partner — from concept to reality.

Category: Blogs

Rosti Group: Advancing Our Transition to Renewable Energy

At Rosti Group, sustainability is at the heart of our operations, and one of the most effective ways we can reduce our environmental impact is by addressing emissions. Energy consumption represents a significant portion of emissions within our value chain, making it a key focus in our commitment to sustainability.

How are Rosti Group supporting customers with Renewable and Recycled Material Selection?

As companies worldwide commit to ambitious global reduction targets and science-based goals, there is a growing need to reduce emissions, adopt sustainable materials, and optimise design and energy use.

Navigating Economic Headwinds with an Injection Moulding Partner

At a time of global economic uncertainty, industries are grappling with challenges that threaten their ability to grow, manufacture, and trade effectively. Market volatility, shifting political landscapes, and supply chain disruptions are reshaping how sectors approach manufacturing and global expansion.

How Rosti is Driving the Zero Waste Element of Its Sustainability Strategy

Rosti Group is taking bold steps towards achieving Zero Waste, a core objective of our Sustainability Strategy.

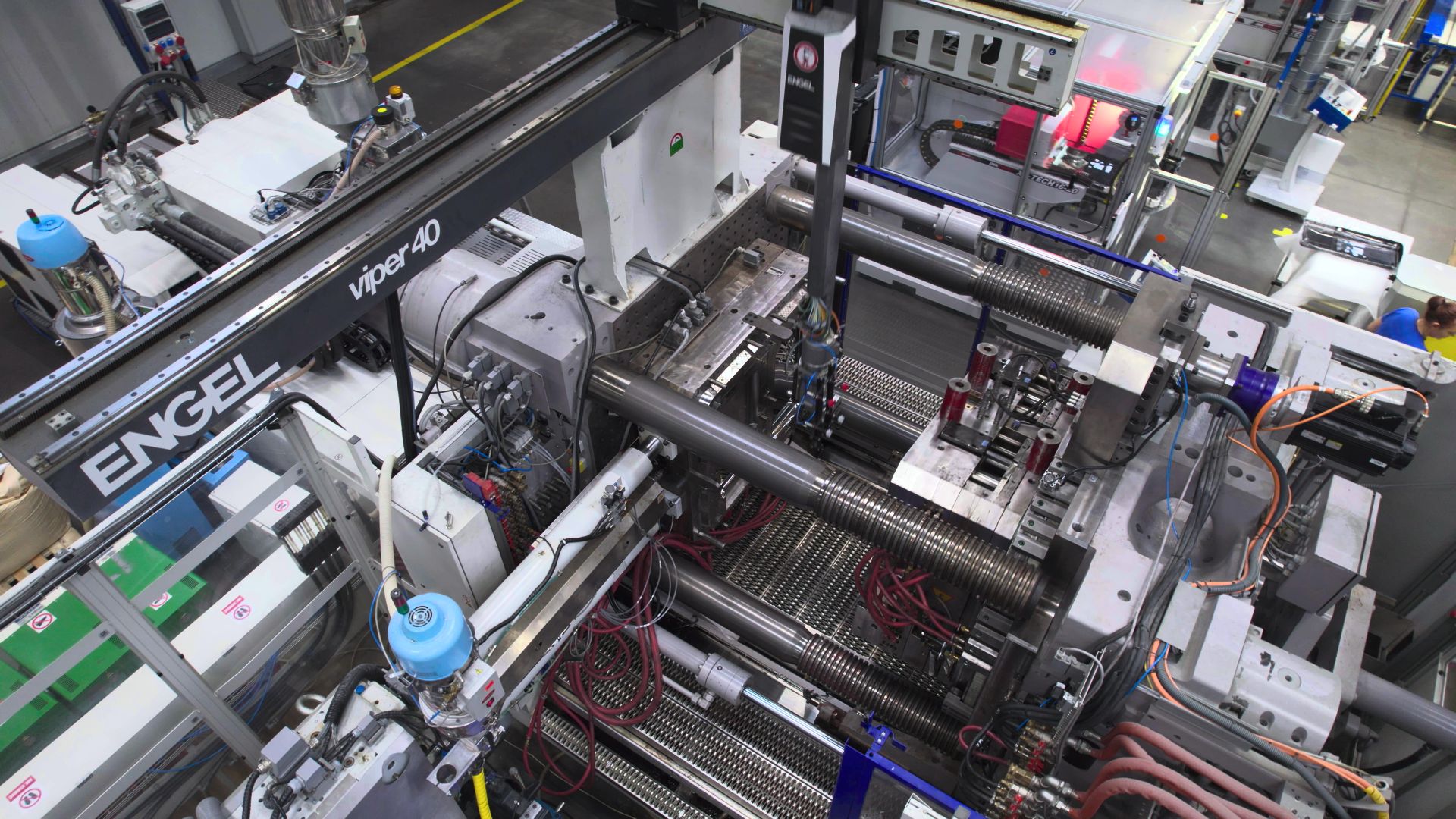

Smart Plastics and Embedded Electronics – Unlocking the Benefits of an Injection Moulding Partner

In a rapidly evolving world, where technology and materials science merge seamlessly, injection moulding of smart plastic components with embedded electronics is a game-changer. These innovative components combine the durability of plastic with advanced electronics, creating products that are lightweight, functional, and versatile.

Supporting the Medical Industry in Limiting Time-to-Market through Innovation Capabilities and 72-Hour Concept-to-Reality Process

In the fast-paced world of medical device manufacturing, time to market is a decisive factor for success. The ability to design, manufacture, and deliver new medical devices at speed is crucial from the perspective of having an impact on patients, meeting regulatory requirements and the commercial success of a device.

Pat Williams – Rosti Asia’s Strategic Expansion into India: Driving Growth in a Dynamic Market

Pat Williams, Senior Vice President Asia, shares his insight on Rosti Asia’s expansion into India, the growth strategy and what it means for our customers.

The Benefits of Choosing a Local Contract Manufacturer with a Global Footprint

Selecting a plastic injection moulding contract manufacturer located in your local market, while also utilising global expertise, offers substantial benefits. Rosti Group exemplifies this blend of strategically located production facilities whilst partnering with the wider group across the globe.

How do Rosti support customers with material selection?

Rosti has a deep knowledge and experience in using an array of materials that comply with stringent sector and international regulatory and compliance standards.