At Rosti, sustainability is more than a policy—it is the foundation of how we design, manufacture, and deliver solutions. As a global injection molder with over 80 years of expertise, we help customers bring sustainable products from concept to reality.

Category: Whitepapers

Plastic Injection Moulding 101

This guide will walk you through a comprehensive overview of the plastic injection moulding process from design through production – including essential elements of moulding.

Advancements in Producing Production Quality Plastic Prototypes

Advancements in production quality prototypes have evolved significantly in recent years.

E-mobility Guide

Rosti works with some of the world’s leading producers to face up to the manufacturing challenges in e-mobility. This is a sector with rapid growth – driven by environmental pressures and government legislation – and we are helping to facilitate the leap from prototype manufacturing to mass production.

Scientific Molding

It’s not hard to understand how computing and innovation have positively impacted industries of all types over the past 35 plus years. The injection molding industry is no exception. Plastic injection molding nowadays is largely based on a scientific approach.

Metal to Plastic Conversion Guide

This guide will help you understand the metal to plastic conversion process, its benefits, and how to partner with your injection molder to collaborate on all design for manufacturability elements.

Design for Manufacturing

This guide will help you understand the importance of DFM, and how to partner with your injection molder during the design validation process prior to tooling kick-off.

Plastic Injection Moulding Tool Transfer Guide

Injection mould tool transfers require organized and upfront planning, communications, and investment to ensure all project goals and expectations are achieved.

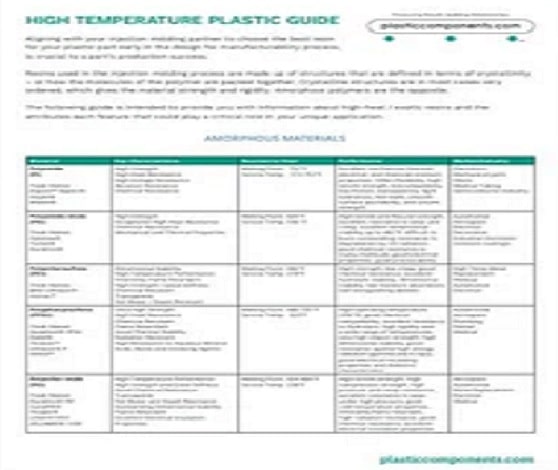

High Temperature Plastic

Are you looking for the best material for the development of a complex plastic part? An important first step in selecting high heat or exotic resins is to understand the key characteristics of materials you are considering for your unique application.

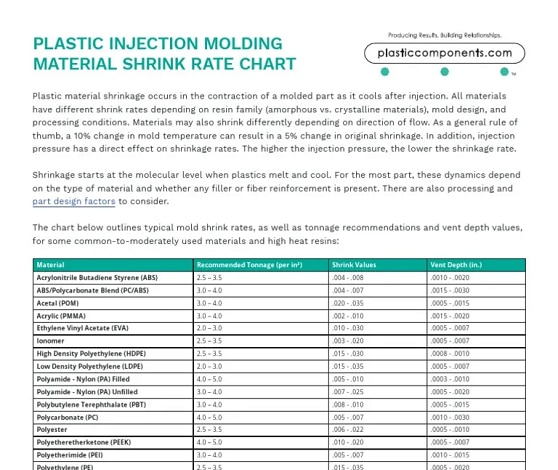

Shrinkage Rate Guide

Plastic material shrinkage occurs in the contraction of a moulded part as it cools after injection. All materials have different shrink rates depending on resin family (amorphous vs. crystalline materials), mould design, and processing conditions.