As the CEO of Rosti Group, reflecting on the journey we’ve embarked on over the years fills me with pride. Since my arrival on the board in 2016, and especially since being appointed CEO in 2020, I’ve witnessed the evolution of our company into a truly global leader in plastic injection moulding. Our transformation has been multifaceted, and I am thrilled to share some insights into this remarkable journey as we mark our 80th anniversary.

Tag: Contract Manufacturing

Hair Product Brand reduce packaging weight by 5% with Rosti Turkey

Rosti Turkey is delighted to support our customer in reducing the tare weight of their packaging by 5%.

Rosti Turkey reduce Cosmetic Packaging weight by 36% using recyclable materials

Rosti Turkey successfully supported a global cosmetic brand to achieve their sustainability objectives by converting the packaging material to Polypropylene, as well as realising the benefits of In-Mould Labelling (IML).

Rosti Group – Your full turn-key Plastic Injection Moulding Partner

At Rosti, we pride ourselves on being large enough to cope with complex injection moulding projects, yet small enough to care, supporting you from concept to reality.

Jonas Persson, CEO, Rosti Group, reflecting on 2023 and Anticipating 2024

Navigating the intricate landscape of global economic shifts and industry trends has been both challenging and enlightening. Looking back at the events that unfolded in 2023 and considering our strategic focus for 2024, I would like to share my insights on our journey, experiences, and our opportunities for the year ahead.

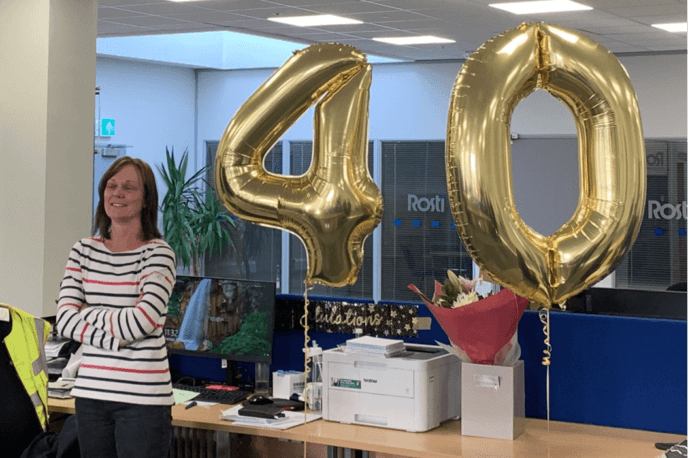

Alex Britland Celebrates 40 Years with Rosti UK

28th November saw Rosti UK celebrate 40 years of hard work and dedication from someone truly awesome here at Rosti UK, Alex Britland, Supply Chain Leader. As we reflect on four decades of commitment, hard work, and innovation, it’s clear that Alex has not just been a part of our organization; she has been an integral force shaping the very essence of who we are. In an era where loyalty to a single workplace is increasingly rare, Alex stands as a beacon of steadfastness, demonstrating that true dedication is a rare and invaluable trait.

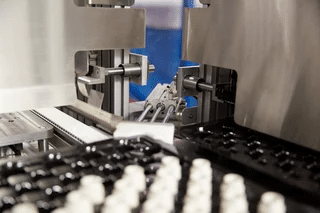

Rosti Germany GmbH celebrates 20th Anniversary

Rosti Germany GmbH is delighted to celebrate 20 years since it was founded under the name GP PLASTINDUSTRI in September 2003. Our production facility in Dresden has continuously grown throughout the two decades, producing up to 4 billion closures for the packaging industry with over 40 injection moulding machines and a team of 80 colleagues.

Rosti’s Tony Austin to Address Reshoring and Contract Manufacturing at Interplas 2023

Reshoring and contract manufacturing roundtable session will include a thought-leader debate on what lies ahead for the industry. European Business Development Technical Director Tony Austin will take the stage during Interplas 2023 on September 26 from 14.00 – 14.45pm at the NEC in Birmingham, United Kindom.

6 Considerations When Choosing A Plastic Injection Moulder

With over 5,500 plastic injection-molding companies in the United States, product manufacturers are challenged with choosing the best partner to help mass produce a product or production element for a business. When you need thousands of parts produced on-time and under budget, having the peace of mind that your injection molder will truly be a partner, and keep your needs in mind, can make all the difference in the world when it comes to getting your product to market faster.

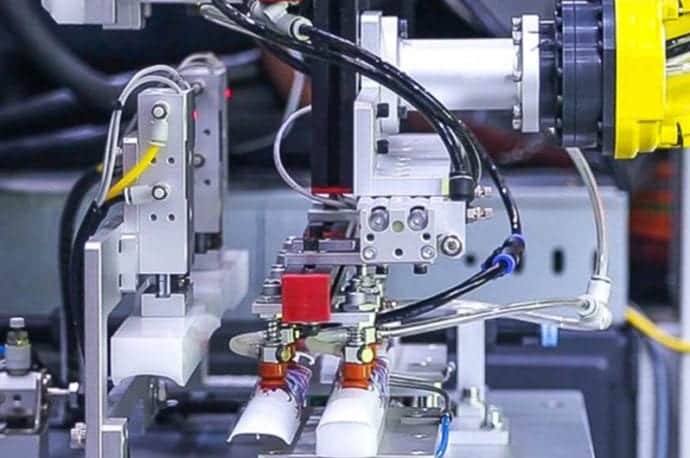

How RJG eDart Transformed PCI’s Injection Moulding Operation

Injection molding technology has evolved greatly since the Hyatt brothers patented the first injection molding machine in 1872. Their initial plunger design was improved upon in 1946 when James Hendry created the first auger injection molding machine. But it wasn’t until the computer age when advances to the injection molding process started to take shape. Today’s plastic injection molders must stay at the forefront with scientific molding principles and processes to meet the demands of quality, consistency, efficiency, production, and cost savings.