Tag: Engineering Support

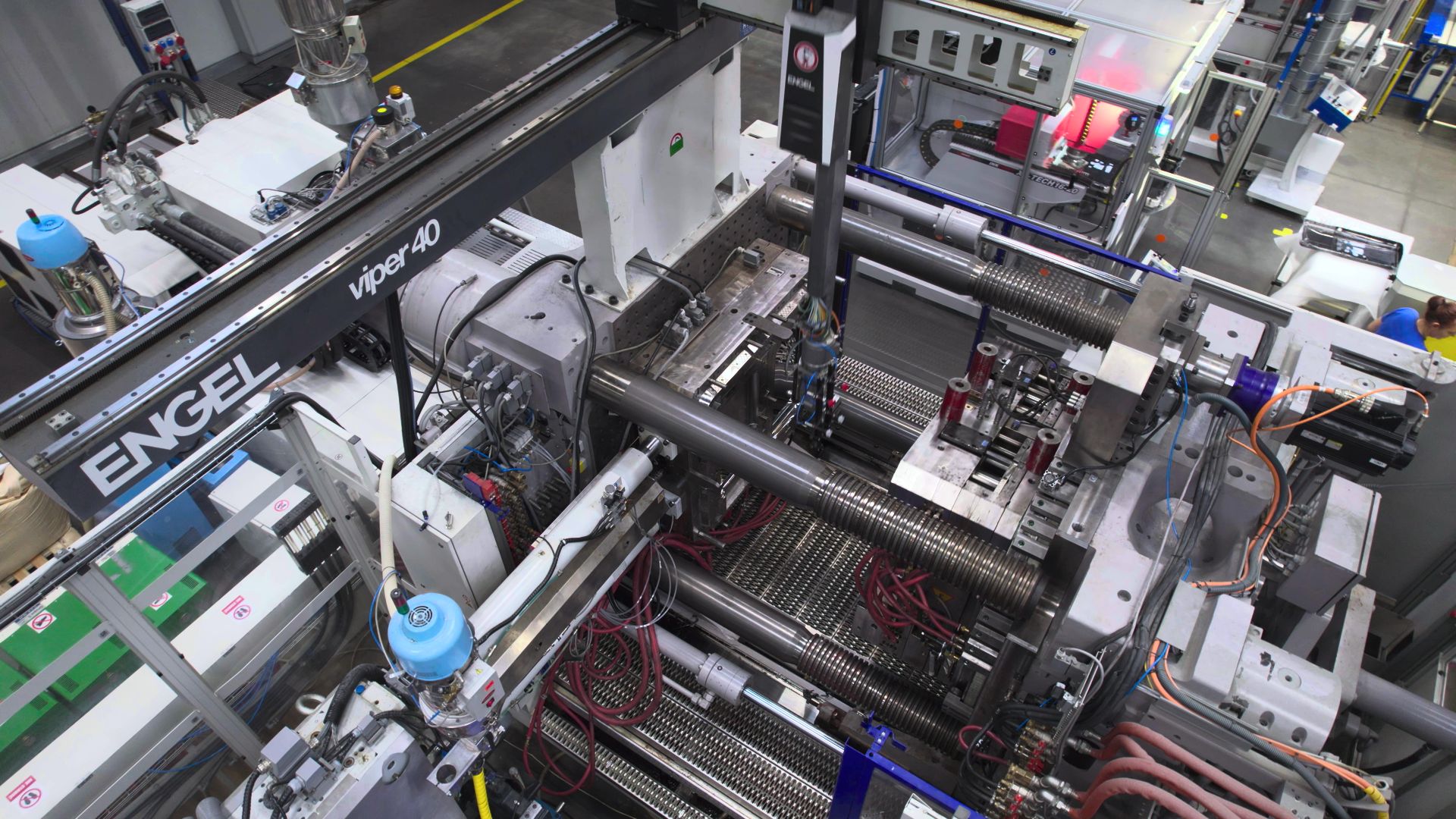

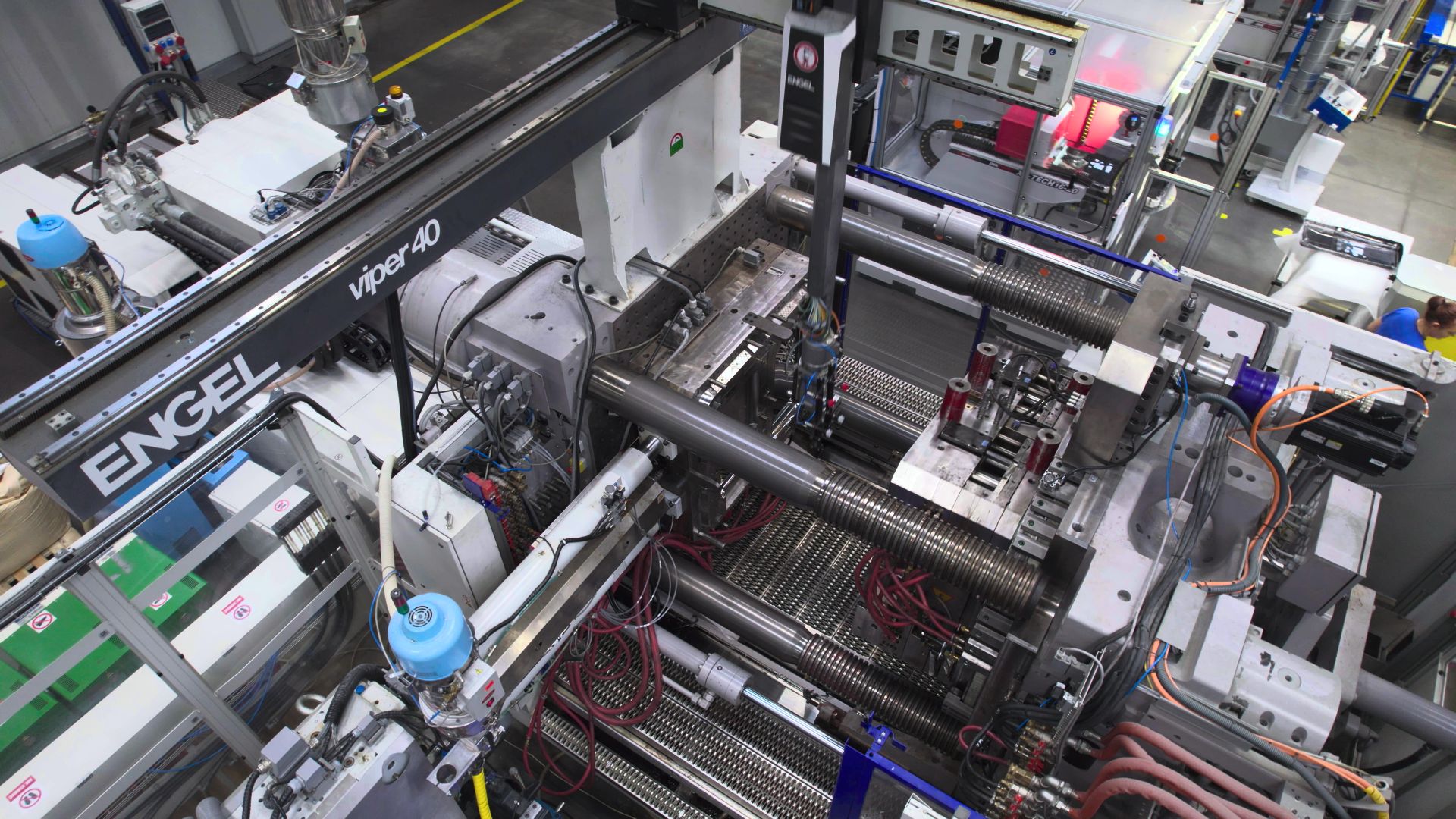

Plastic Injection Moulding 101

This guide will walk you through a comprehensive overview of the plastic injection moulding process from design through production – including essential elements of moulding.

How are Rosti Group embracing AI in Injection Moulding?

Scott Dickson, Technology & Innovation Director at Rosti Group, shares his perspective on how we are embracing AI to enhance our global plastic injection moulding capabilities. From driving efficiency and improving quality to accelerating innovation across our global facilities, Scott explores the practical ways AI is shaping the future of manufacturing.

Achieve Functional Design and Sustainability through Multi-Shot Injection Moulding

Multi-shot injection moulding is rapidly emerging as a key technology in the evolution of product design and sustainable manufacturing.

Design Support for the Future – Global Design Drives Innovation and Sustainability for Plastic Injection Moulding

In today’s fast-paced, environmentally conscious world, the pressure is on for businesses to deliver innovative products that are not only high-performing and cost-effective but also sustainable.

Smart Plastics and Embedded Electronics – Unlocking the Benefits of an Injection Moulding Partner

In a rapidly evolving world, where technology and materials science merge seamlessly, injection moulding of smart plastic components with embedded electronics is a game-changer. These innovative components combine the durability of plastic with advanced electronics, creating products that are lightweight, functional, and versatile.

Rosti Group’s Partnership with Global Energy Storage Leader in E-Mobility Solutions for Large Vehicles

In 2017, Rosti Group embarked on a strategic partnership with a German energy storage company focused on advancing e-mobility solutions for large vehicles such as buses, coaches, and heavy goods vehicles (HGVs).

Rosti Group to Showcase Advanced Medical Solutions Manufacturing Capabilities at MedtecLIVE 2024

Rosti’s MedtecLIVE 2024 exhibit will showcase next-generation medical manufacturing featuring advanced prototyping, custom manufacturing solutions, industry-leading design collaborations, cutting-edge carbon technology, and more.

Design Is Top Consideration To Reduce Plastics Manufacturing Costs

Plastics manufacturing is a highly competitive, global industry in which businesses are presented with both time and cost challenges. Avoiding delays and reducing risks for costly design changes can mean that your product gets to market faster than your competitors. The sharp line that was once drawn between development and production is now, oftentimes, blurred with manufacturers leaning on industry design experts to become involved in the design for manufacturability process. In fact, manufacturers rank design as the top factor in reducing overall manufacturing costs.

Plastic Residence Time: Calculation and Process

From the specific plastic you are using, your mold, temperature, material density, and the machine itself and its individual parts, there are a number of variables that can make or break the injection molding process. One thing is certain: Processing too long or too short outside of the recommended plastic residence time can cause significant quality issues. Worse yet, not all resulting problems are immediately visible – inconsistency in melt quality, color variation, or weakened parts.