Rosti is committed to sustainability and reducing our environmental impact.

As a plastic moulding company and contract manufacturer, Rosti sits at the center of the supply chain and has a duty and an opportunity to make a positive environmental impact on the plastics industry.

Introducing

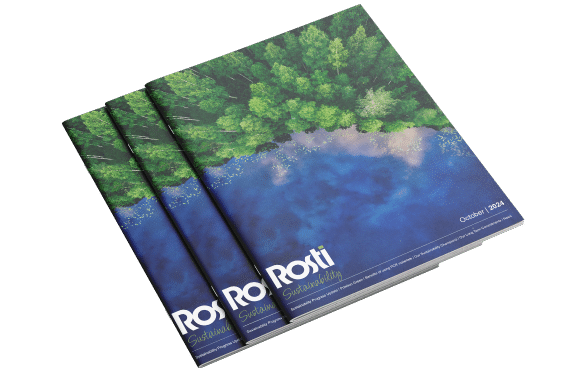

Inside Rosti Sustainability October | 2024

Jonas Persson, CEO

“Everyone in Rosti, at every point of the value chain, understands what we are doing and should be doing to reduce our and our customers' global impacts.”

Our design for manufacturing processes can directly affect product design, material selection and waste handling, and we have influence throughout the entire supply chain from raw materials to finished goods and beyond. This is why we put our commitment to creating sustainable initiatives at the heart of our overall business strategy, and it is why we give careful consideration to our choices at every step in the process.

Working closely with our customers and partners to help them understand the benefits of sustainable manufacturing processes, together, we can make a positive impact on the plastics industry and create a more sustainable future for all.

Our Sustainability

Strategy Ambitions

Read our Rosti Sustainability Framework Document or Rosti Sustainability Report 2024 to find out more.

1

Continuously working

Continuously working with our customers and suppliers to interact with our local and wider communities to understand their sustainability goals.

2

Design

To design for environmental sustainability, by considering the environmental impact of the choices we make.

3

Leave no trace

To strive to ‘leave no trace’ from our operations, by improving our input-output balance and by adding maximum value to every step in the process.

Recycling

All scrap recovered to re-grind and re-used where possible.

Design

R&D efforts to develop lighter products minimising resin inputs. Engagement in innovative products to replace single use packaging.

Production

Modern efficient machines ensuring energy efficient manufacturing and Operation Clean Sweep (zero pallet loss).

Distribution

Recycle packaging used throughout the factory.

Consumption

Re-usable packaging solutions and serviceable products/spare parts that maximise product life cycles.

Green Resin

Use of bio based resins within our packaging business.

Recycling

All scrap recovered to re-grind and re-used where possible.

Design

R&D efforts to develop lighter products minimising resin inputs. Engagement in innovative products to replace single use packaging.

Production

Modern efficient machines ensuring energy efficient manufacturing and Operation Clean Sweep (zero pallet loss).

Distribution

Recycle packaging used throughout the factory.

Consumption

Re-usable packaging solutions and serviceable products/spare parts that maximise product life cycles.

Green Resin

Use of bio based resins within our packaging business.

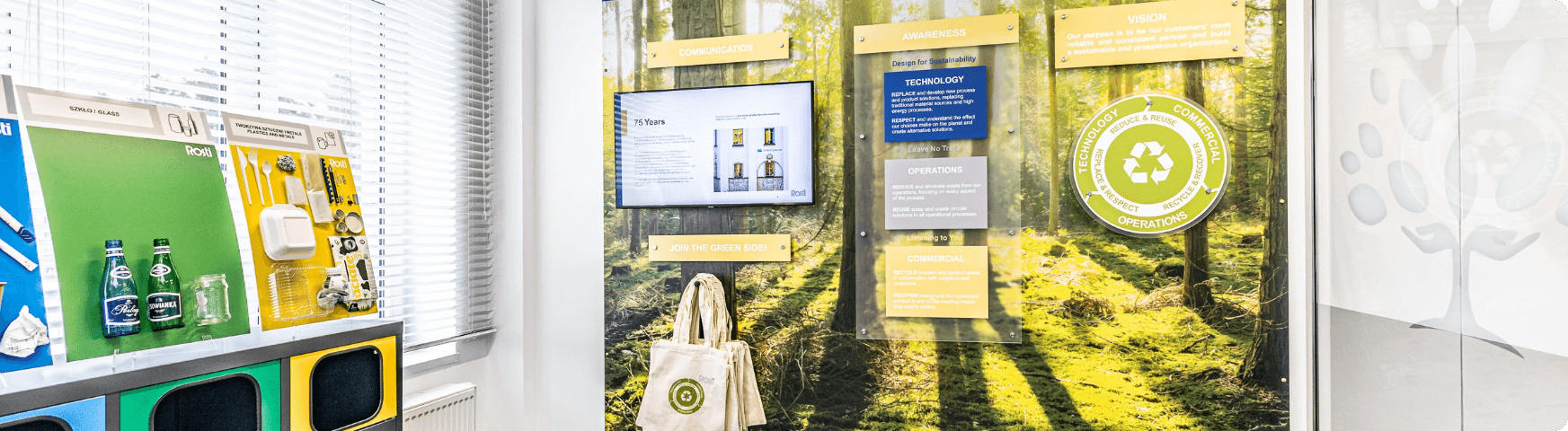

Rosti and the Circular Economy

Rosti are committed to supporting the need to improve the environment for future generations.

Throughout our industry, we are seeing a shift from a linear economy to a circular economy, with material selection and end-of-life product recycling becoming critical considerations in our sustainable business strategy. At Rosti, we make detailed analyses of new products at the concept design stage, so that they better fit the circular economy model. These analyses look at material selection, tooling management, production technology, and the products’ potential for repair or recycling.

We have a deep belief in the need to move towards a circular economy, and this drives us to work with advanced material developers, machine producers and our customers to support our community and our planet. These efforts are rooted in our values of partnership and integrity, and we take tangible actions to lessen our impact on the natural world.

These sustainability initiatives include:

- Reduce and Reuse

- Operating an internal energy management program

- Creating lightweight solutions

- Improving packaging

- Recycle and Recover

- Using recycled feedstock

- Reprocessing our internal scrap

- Designing repairable products with extended life cycles

- Replace and Respect

- Using bio-based feedstock materials

- Process elimination

- Metal-to-plastic conversion

Spotlight:

On-Site Strategy Examples

As well as our company-wide sustainability policy, all our sites take independent actions to address their environmental impact.

Here are a few of the ways that they incorporate sustainable business practices into their day-to-day operations.

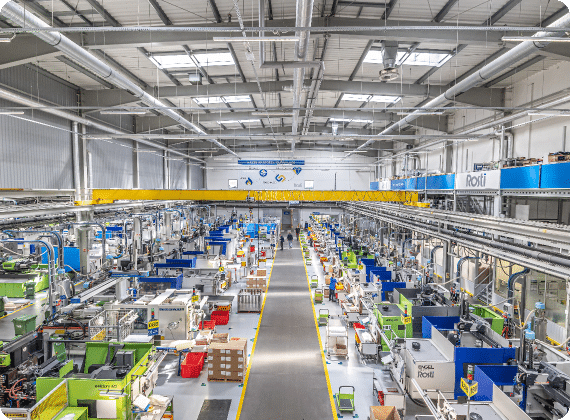

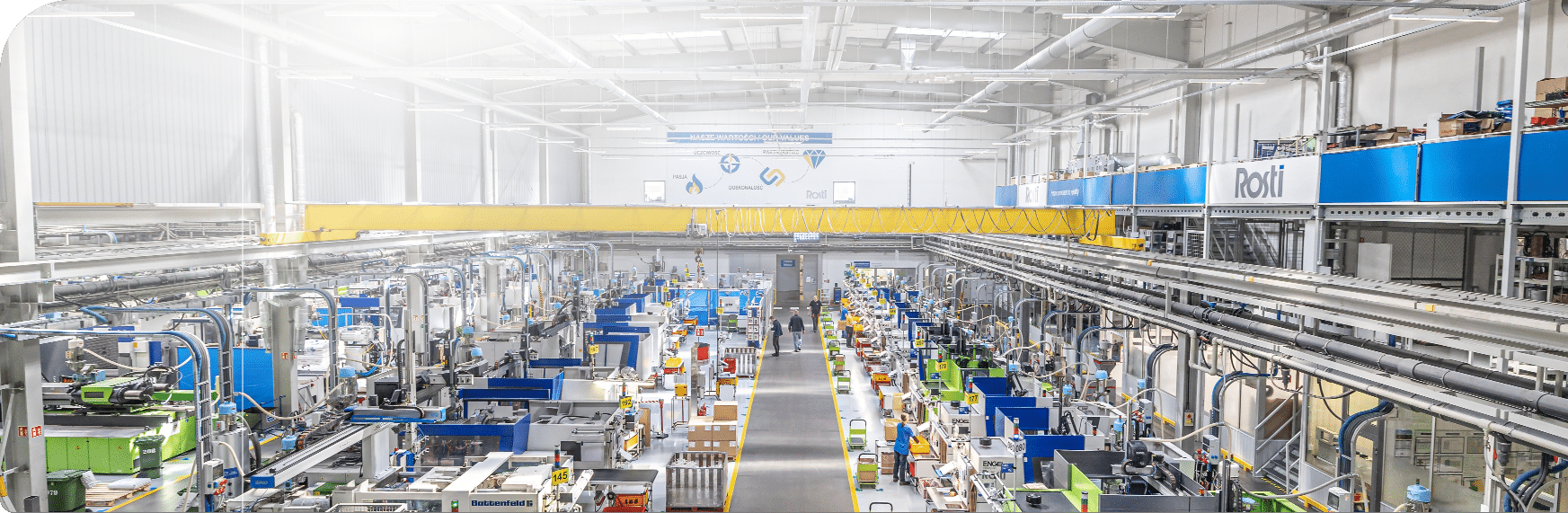

Rosti Europe

Our sites across Rosti Europe are dedicated to developing unique and innovative sustainability initiatives, and we’re committed to upholding high environmental standards.

Examples include:

- Supporting our customers in emission reduction – providing Product Carbon Footprint (PCF) calculation tools and guidance to help reduce emissions.

- Designing for recyclability – collaborating with customers to minimize plastic content and enhance the recyclability of products.

- Sustainable materials alternatives – We’ve helped customers from 10 sectors changed materials in their products to more green alternatives.

- Sustainable packaging – enable transition to reusable and returnable packaging solutions.

- Using renewable energy sources – we are progressively transitioning to 100% clean energy.

- Self-generated renewable power – investing in systems that enable on-site energy generation from renewable sources.

- Modernizing our machinery park – upgrading equipment to improve energy efficiency and minimize heat losses.

- Energy recovery – harnessing heat generated by machines as a secondary energy source.

- Reducing energy losses – optimizing production processes, compressed air systems, ventilation, and installation insulation.

- Smart energy management – implementing automated controls, sensors, and intelligent lighting systems to reduce unnecessary energy use.

- Recycling production waste – reusing materials and striving to minimize waste at every stage of production.

Rosti Asia

Our sites in China and Malaysia are taking significant steps to minimise our environmental impact by prioritising our own sustainability initiatives.

Examples include:

- Decreasing energy consumption by replacing fluorescent lamps with energy-efficient LED versions.

- Updating injection moulding machinery with more energy-efficient models, featuring servo motor control systems and hydraulic machines.

- In office areas, air conditioning systems operate on a timer. Plans are underway to extend the use of timers and movement sensors to lighting systems.

- In office areas, air conditioning systems operate on a timer. Plans are underway to extend the use of timers and movement sensors to lighting systems.

- Implementing waste reduction projects to decrease waste from the moulding process.

- Utilising preventative maintenance strategies to effectively reduce the production of mixed oil and waste.

Rosti North America

Recently acquired, Rosti US has joined the Rosti group and embarked on our sustainability journey, aligned with the Rosti agenda.

Examples include:

- Launched a company-wide initiative on ‘Earth Day’ to clear debris from the surrounding properties.

- Allocated capital expenditure to transition all plant lighting to energy-efficient LEDs.

- Arranged a visit from a global energy consultant in Q4.

Get in touch

We are only a message away.

Our expertise and global footprint, over sites strategically placed in the Europe, Asia and USA, make Rosti your local plastic injection moulding partner.

Contact us today and one of our team will respond to your enquiry.