The home appliance and building management sectors are undergoing a fundamental shift. Products that were once mains powered, mechanically simple, and manufactured close to a single end market are now evolving into intelligent, connected, and increasingly cordless battery-powered devices designed for the global market.

From smart home devices and sensors to portable, cordless appliances and monitoring systems, this transition is redefining how products are designed and manufactured. For OEMs and global brands, the choice of manufacturing partner has never been more critical.

The need for an injection moulding partner with deep, proven expertise in high-volume, complex plastic injection moulding is essential. Secondly, collaborating with a partner who can tailor support around your contract manufacturing requirements across a global footprint of plastic injection moulding facilities can provide a competitive advantage.

Proven Experience in Manufacturing Cordless Products

Home appliances and building management products sit at the intersection of performance, aesthetics, and reliability. Components must meet standards for strength, temperature resistance, hygiene, and performance often while remaining aesthetically pleasing for the consumer market.

At Rosti, we have decades of experience in delivering high-volume programmes for this sector, building a reputation moulding parts to high specifications. It requires a contract manufacturing partner capable of managing complexity end-to-end.

This includes:

- Product design and innovation for cordless solutions – ensuring manufacturability, cost efficiency and sustainability are built in from the earliest stages

- Precision plastic injection moulding – including complex geometries, tight tolerances, and high-cavity tooling

- Multi-K and decorative technologies – supporting premium aesthetics, overmoulding, and integrated functional surfaces

- Automated production and assembly – enabling consistent quality at scale

- Integrated logistics and supply chain support – aligned to customer production and market demand

For global OEMs, this level of capability must be available consistently across regions. A fragmented supply chain where design, tooling, moulding, and assembly are split across multiple suppliers and geographies potentially increases supply chain risk and cost. A single, coordinated manufacturing partner enables far greater control, speed, and resilience.

Cut the Cord – the shift to Cordless Battery Technology

One of the most significant changes across both home appliances and building management is the move away from mains-powered products. Cordless, Battery-powered and low-energy devices are becoming the norm, driven by flexibility of installation, energy efficiency, and the growth of smart, connected infrastructure.

This shift has wide-ranging implications for product design and manufacture:

- Enclosures must accommodate battery technology safely and efficiently

- Materials must support thermal management, strength, and long-term stability

- Components must integrate seamlessly with electronics, sensors, and communication modules

- Manufacturing processes must ensure repeatability, reliability, and compliance at scale

Battery-powered products also tend to be smaller, more compact, and more design-led. This places additional emphasis on precision moulding, tight tolerances, and the intelligent use of multi-material solutions.

Embedded Electronics as a Core Capability

Embedded electronics are now central to how cordless modern appliances and building systems operate. Whether enabling communication, monitoring environmental conditions, collecting data, or powering intelligent control systems, electronics are no longer an add-on -they are integral to the product architecture.

Supporting this evolution requires close collaboration between design, engineering, and manufacturing teams. Plastic components are no longer only housings; they play an active role in protecting electronics, managing heat, enabling signal transmission, and supporting assembly efficiency.

Key areas where this expertise adds value include:

- Multi-K injection moulding – combining structural, aesthetic, and functional materials in a single component

- Compliance and standards – including anti-bacterial requirements, food contact standards, and temperature resistance

- Scalable production – from early-stage validation through to high-volume global programmes

By embedding electronics expertise within the manufacturing partnership, OEMs can accelerate development timelines, reduce re-engineering, and bring more robust cordless products to market.

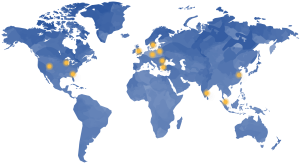

Manufacturing Close to the End Market

As products become more complex and markets more dynamic, localisation of manufacturing is increasingly important. Customers want the ability to manufacture close to their end markets – reducing lead times, managing risk, and responding quickly to demand.

Rosti’s global manufacturing footprint of 13 sites, unified by consistent processes, quality systems, and engineering standards, enables exactly that. Tooling, knowledge, and production can be transferred or replicated across Europe, Asia and North America, allowing customers to scale efficiently while maintaining identical outputs worldwide.

This flexibility is particularly valuable in sectors experiencing rapid technological change, where speed to market and adaptability are competitive differentiators.

Rosti – your strategic injection moulding partner for cordless products

For OEMs, working with a precision injection moulding partner that combines contract manufacturing capabilities with advanced design and electronics expertise is no longer optional. It is a strategic necessity for delivering the next generation of intelligent, reliable, and market-ready cordless products.