Services, Processes, and Advantages

Not every company or agency has the resources, budget, or time to handle everything internally – no matter how ideal that may seem – especially in the manufacturing sector. Purchasing equipment, machinery, and specialised expertise can be expensive. That’s why contract manufacturing has become a widely used solution.

So, what exactly is contract manufacturing, and how does it work? Let’s break down the meaning behind the word.

What You Will Learn in This Article:

- What contract manufacturing is and how it works

- The different types of contract manufacturing services

- Step-by-step overview of the contract manufacturing process

- Key benefits of contract manufacturing for businesses

- Potential risks and challenges to be aware of

- How to choose the right contract manufacturer for your needs

What is Contract Manufacturing?

Contract manufacturing happens when one company partners with a specialised manufacturer to produce specific components or products for a set period of time. Think of it as outsourcing production to experts who can deliver exactly what you need, when you need it.

In a typical arrangement, a contract manufacturer produces parts, components, or even complete products according to the client’s specifications. These items are then used by the client in their own manufacturing process or incorporated into their final products. Many contract manufacturers operate as third-party specialists, either focusing solely on subcontracting or supplying products to multiple companies.

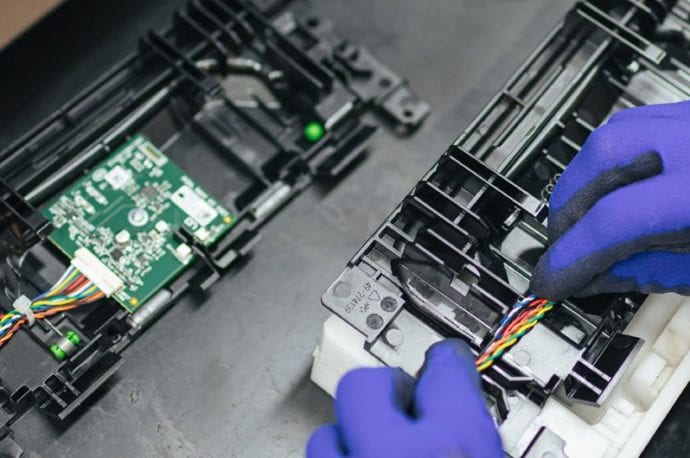

For example, a global supplier in the consumer electronics industry turned to a leading plastic injection moulding manufacturer to produce precision-moulded components for its assembly lines on a contract basis. The moulding partner met the client’s “Just in Time” demands by combining speed, engineering expertise, and advanced automation to deliver consistent, high-quality parts at scale.

What is the Definition of Contract Manufacturing Services?

Contract manufacturing services go beyond simply producing parts. They encompass the full range of support a company receives when partnering with a specialised manufacturer – from design and engineering to fabrication, assembly, and testing – all tailored to meet exact specifications.

By leveraging these services, companies can access advanced technology, skilled labor, and flexible production capacity without the overhead of building in-house capabilities. This partnership ensures faster lead times, reduced costs, and reliable quality control — helping businesses stay competitive while focusing on their core strengths.

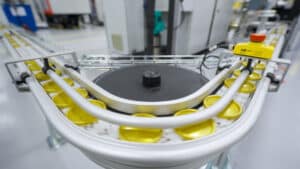

Providers, such as Rosti, demonstrate how these services work in practice. With expertise spanning tooling, plastic injection moulding, assembly, and logistics, and global facilities that emphasise flexibility, quality, and sustainability, Rosti enables companies to bring products to market faster and respond effectively to evolving customer needs.

Read more: How Rosti works with contract manufacturing in plastic injection moulding.

Contract Manufacturing Process – How does it work?

As you know by now, contract manufacturing can take many forms, depending on what a company needs. Some businesses only need help with product design or assembly, while others rely on a partner for the entire production process from start to finish.

In general, contract manufacturing services fall into 4 different types:

- Product Design

- Manufacturing

- Assembly

- End-to-End Production

Your specific process will depend on which of these services you choose. Some manufacturers let you combine services – like design plus manufacturing – while others offer full, end-to-end solutions that handle everything for you.

Even though the details may vary from company to company, most contract manufacturers follow a similar process. Here’s a closer look at what that typically involves:

1. Product Design

If you’re starting with an idea or concept, this is where your contract manufacturer helps bring it to life.

Step 1: You’ll first sign a contract or service-level agreement (SLA) that includes important details such as intellectual property (IP) rights.

Step 2: You’ll then meet with engineers to refine and finalise your product design for manufacturability.

Step 3: The engineers will build and test prototypes – often multiple times – until the final version meets your expectations.

Step 4: Once finalised, they’ll store a detailed digital model using a design system.

Step 5: Finally, you’ll start discussing production goals, quantities, and expectations.

2. Manufacturing

Once your design is ready, production can begin.

Step 1: You’ll sign a manufacturing SLA (if it wasn’t included earlier) that outlines volume, cost, and timelines.

Step 2: The manufacturer creates custom moulds, tools, or dies needed for production.

Step 3: A short test run is performed to ensure everything meets quality standards.

Step 4: After testing, the manufacturer moves into full production, performing quality control checks after every batch to ensure consistency and precision.

3. Assembly

This stage focuses on putting everything together and preparing the product for shipment.

Step 1: The manufacturer assembles all components and tests the finished product to confirm it works properly.

Step 2: Once approved, the product is packaged and labelled based on your shipping instructions – whether it’s going directly to customers or to a warehouse.

Step 3: The finished products are shipped, and each shipment’s progress is tracked for full transparency.

Step 4: After production, the manufacturer transfers all relevant documentation – CAD files, prototypes, and unused moulds – to you.

Step 5: In some cases, the manufacturer will securely store moulds or digital files, making it easy to reorder or reproduce the same products in the future.

4. End-to-End Contract Manufacturing

Complete product manufacturing – also called turnkey production or end-to-end contract manufacturer – is when a manufacturer handles the entire process from start to finish. The big advantage of this model is flexibility: they can start or stop at any point in the process, depending on what you need.

For example, if you already have a solid design, they can jump straight into prototyping and production. Or, if you prefer to handle packaging and distribution yourself, they’ll simply manufacture the components or products and hand them off to you.

No matter where you are in your product development journey, an end-to-end manufacturer can step in and help you move forward efficiently and cost-effectively.

Whether you’re launching a new business, scaling production, relocating operations, or seeking a manufacturing partner, Rosti offers flexibility, reliability, and expertise. Watch this video to see how we work.

Contract Manufacturing Example

Contract manufacturing plays a vital role across many industries, allowing companies to focus on their core strengths while trusted partners handle specialised production tasks.

In the medical sector, companies can leverage Rosti’s contract manufacturing services to meet the growing demand for personalised and high-precision plastic components. Here is an example:

Imagine a medical device company that wants to develop a new wearable health monitor or a custom diagnostic kit. These devices require small, precise, and biocompatible plastic components, which can be difficult and costly to produce in-house.

Instead of doing everything internally, the company partners with Rosti for contract manufacturing. Here’s how the process works:

- Design and Tooling: Rosti helps create the designs and tools needed to produce the plastic parts with exact specifications.

- Injection Moulding Production: Using advanced plastic injection moulding, Rosti manufactures the components in small batches, ensuring precision and quality.

- Assembly and Quality Control: Components are assembled into sub-systems or complete devices, with rigorous quality checks and compliance with medical sterilisation standards.

- Advanced Techniques: For complex or custom parts, Rosti may integrate 3D-printed inserts or other hybrid manufacturing methods. Automation and IoT-enabled monitoring ensure consistent quality and efficiency throughout production.

By using Rosti’s services, the medical company can:

- Quickly prototype and test new designs

- Scale production as needed

- Maintain high standards for safety and biocompatibility

- Reduce costs and optimise material use

Read more: 4 Key Trends for Medical Plastic Injection Moulding.

Benefits of Contract Manufacturing

Partnering with a contract manufacturer offers businesses a wide range of advantages – from saving money and time to improving product quality and market reach. Here are some of the biggest benefits:

1. Cost Reduction

One of the biggest advantages of contract manufacturing is lower operating costs.

By outsourcing production, companies can avoid the huge expenses of buying, maintaining, and upgrading manufacturing equipment. They also eliminate the need to hire and manage large in-house production teams – complete with salaries, benefits, and training costs.

Contract manufacturers already have the facilities, skilled staff, and specialised tools in place. That means your company only pays the agreed-upon contract amount (plus any applicable service fees), without carrying the ongoing financial burden of production overhead.

2. Better Use of Resources

Outsourcing production also helps companies redirect their resources where they matter most.

The money saved from not having to run a full-scale production operation can instead go toward marketing, research and development, sales initiatives, or expanding into new markets.

When manufacturing is handled externally, your internal teams can focus on what they do best – strengthening the company’s core values, strategy, and customer relationships.

3. Faster Production and Delivery

Contract manufacturers often specialise in speed and efficiency. By outsourcing certain parts or components, companies can shorten their overall production timelines and bring products to market faster.

This boost in turnaround time not only improves customer satisfaction but also enhances competitiveness – especially in industries where timing can make or break success.

4. Easier Market Entry

Working with a contract manufacturer can also make it easier to enter new markets or scale existing operations.

By maintaining consistent, high-quality production standards, companies can build brand trust and recognition more quickly. Reliable manufacturing partners help ensure that products meet regulatory standards and customer expectations – both of which are key to long-term success.

Consistent quality also helps strengthen relationships with distributors, partners, and potential investors – opening the door to future opportunities and collaborations.

Risks of Contract Manufacturing

While contract manufacturing offers many advantages, it also comes with potential challenges. Understanding these risks can help companies make smarter outsourcing decisions.

-

Limited Control

When production is outsourced, the client sets the product requirements, and the manufacturer manages the manufacturing process. While day-to-day oversight may be limited, companies can maintain alignment by providing clear specifications, regular check-ins, and open communication. Contract manufacturers can also offer recommendations to enhance design or efficiency, which can improve the final product if implemented collaboratively.

-

Quality Management

Outsourcing requires careful selection of a manufacturing partner. Differences in standards or miscommunication can impact product quality. These risks can be minimised by choosing experienced manufacturers, defining clear quality criteria, and establishing effective communication channels. With the right approach, companies can achieve consistent, high-quality production while benefiting from specialised expertise.

-

Workforce Considerations

Shifting production externally can affect in-house teams, requiring reassignment or retraining for employees previously involved in manufacturing. By planning transitions thoughtfully, companies can manage workforce impacts responsibly while freeing internal resources to focus on core business activities.

What Is the Biggest Risk in Global Contract Manufacturing?

Entering a global contract manufacturing agreement requires careful planning. While all manufacturing involves some risk, expanding production internationally introduces additional factors to consider. Understanding these challenges can help companies make smarter decisions and maximise the benefits of global partnerships.

-

Quality Control

Lower production costs are a key reason companies look overseas, but distance can make quality oversight more complex. By establishing clear specifications, robust quality protocols, and regular communication with the manufacturer, companies can maintain high-quality standards and ensure products meet customer expectations.

-

Supply Chain and Logistics

Global supply chains can face disruptions, from shipping delays to unforeseen events like factory shutdowns. Proactively managing logistics, building in contingencies, and maintaining transparent communication with suppliers can help minimise delays and maintain smooth operations.

-

Intellectual Property (IP) Protection

Outsourcing internationally requires careful attention to IP security. Using contracts, legal safeguards, and trusted manufacturing partners can protect designs, formulas, and proprietary processes while enabling companies to benefit from global production capabilities.

-

Choosing the Right Partner

Finding a dependable overseas manufacturer takes time and effort, but thorough vetting, site visits, and reference checks can identify partners who meet quality and production standards. Once established, these relationships provide access to specialised expertise, scalable capacity, and international market advantages.

How to Choose the Right Contract Manufacturer

Selecting the right contract manufacturer is one of the most important decisions a company can make. The right partner can help streamline production, reduce costs, and protect your brand reputation, while the wrong one can introduce risks. Here are the key characteristics to look for when evaluating a contract manufacturer:

1. Quality Facilities

A visit to a manufacturer’s facility can tell you a lot about their operations. Look for a clean, well-organised, and efficiently run facility. Machines and equipment should be well-maintained, and staff should be experienced, knowledgeable, and professional. A structured production process indicates reliability and the ability to deliver consistent results.

2. ISO Certification

Quality standards and certifications matter. Choose contract manufacturers that are ISO-certified, particularly ISO 9001:2015, which ensures their quality management systems meet global standards. Certified manufacturers are more likely to produce high-quality parts, components, and products consistently, giving you confidence in the final output.

3. Clear Communication

Open and responsive communication is essential for a successful partnership. Reputable manufacturers keep clients informed throughout the design and production process, quickly addressing questions or production adjustments. A partner who communicates well minimises misunderstandings, reduces delays, and helps your project stay on track.

4. Market Awareness

Top contract manufacturers do continuous improvements and stay tuned into industry trends and market conditions. They adapt to changing demands, regulatory updates, and evolving customer expectations. A manufacturer with a strong presence and reputation in their industry signals reliability and professionalism, giving you confidence in their ability to support your business long-term.

The Rosti Way exemplifies our core values; Passion, Integrity, Partnership and Excellence. These values guide us in everything we do. Read more about how we work – The Rosti Way.

Choose Rosti as Your Contract Manufacturing Partner for Plastic Injection Moulding

With decades of experience and a track record of innovation, Rosti delivers cutting-edge technology for plastic injection moulding services around the globe — and far beyond. Our managed and contract manufacturing services cover the full spectrum, from initial product concept and design to production, assembly, logistics, and delivery. With this breadth of capabilities, we can support you at every stage of the manufacturing process.

Over the past 20 years, we have carefully managed our growth to maintain the flexibility and accessibility that define our approach to contract manufacturing. This balance allows us to deliver successful projects for small businesses as well as some of the world’s largest companies.

Contact us to discover how we can help with your contract manufacturing needs.

Frequently Asked Questions

What is a Contract Manufacturing Organisation?

A Contract Manufacturing Organisation (CMO) is a company that provides manufacturing services to other businesses on a contractual basis. Instead of producing products in-house, a company can partner with a CMO to design, produce, assemble, or package its products. CMOs are widely used in industries where specialised expertise, equipment, or capacity is needed, such as pharmaceuticals, medical devices, consumer electronics, and plastics.

How does Rosti Ensure Quality and Compliance?

At Rosti Group, quality and compliance are at the heart of everything we do. All 12 of our facilities hold internationally recognised certifications, including ISO 9001, ISO 13485, ISO 14001, and ISO 50001, ensuring high standards for quality, sustainability, and energy management.

Our teams follow robust quality assurance processes, including product validation, in-line inspections, and traceability systems, while meeting strict industry and regulatory requirements for sectors such as medical devices, automotive, and consumer goods. Through continuous improvement, data-driven monitoring, and close customer collaboration, we consistently deliver safe, reliable, and high-quality products.

How does Rosti Support Sustainability Goals?

Sustainability is a core focus throughout Rosti’s contract manufacturing process, starting from the design and innovation phase. We work to identify opportunities to reduce environmental impact, offering sustainable and recyclable materials, energy-efficient machines, and automated “lights-out” production that minimises waste and improves material utilisation.

Even in logistics and delivery, sustainability remains a priority. Our team supports customers in selecting lightweight, returnable, or recyclable packaging, helping to lower emissions while ensuring products arrive safely and maintain the highest quality standards.