Across industries as diverse as automotive, medical, consumer goods, food and beverage, and industrial processing, demand for advanced filtration systems is on the rise.

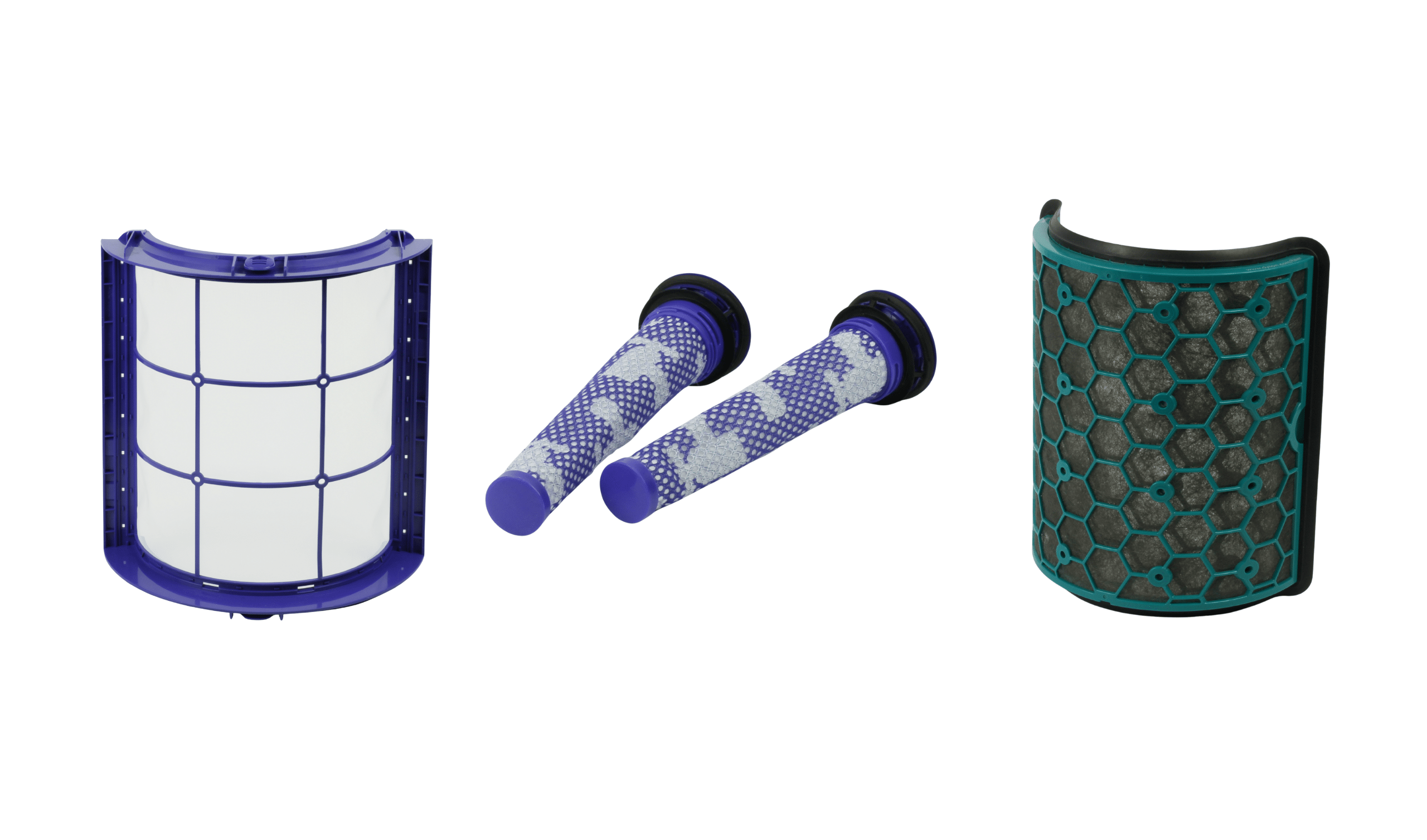

From particulate and mesh filters to complex housings and membrane holders, filtration components play a vital role in ensuring safety, performance, and compliance. Yet producing these components presents unique manufacturing challenges — particularly when working with fine mesh materials and porous membranes that must be handled with precision.

At Rosti Group, we bring a wealth of experience in plastic injection moulding to support customers in meeting these challenges. Our capabilities enable the manufacture of complex geometries and non-uniform components, offering high-volume repeatability, integration of multiple parts, and consistent quality.

Why Plastic Injection Moulding is the right fit for Filtration

Plastic injection moulding offers the ability to mould delicate components with tight tolerances, such as supports, housings, and media interfaces. The process allows multiple components to be consolidated into a single moulded unit, reducing assembly time and cost while improving performance and durability.

Handling filtration media, particularly thin membranes or mesh, requires specialist knowledge. These materials are porous, flexible, and sensitive to temperature, pressure, and alignment. We work closely with clients from the earliest design stages to ensure optimal integration into moulded parts.

Expertise in Filtration Injection Moulding

Rosti has a proven track record supporting global brands in the consumer goods and household appliance sectors, helping bring filtration products to life from concept through to full-scale production. Our approach includes:

- Collaborative design: Working with customers on product development to balance functional performance with manufacturability.

- Precision tooling: Creating multi-cavity tools with tight tolerances for repeatable performance.

- Automation: Including bespoke in-house robotics and conveyor towers for handling and assembly.

- Material selection: Recommending materials that balance performance, regulatory compliance (food-grade, medical, etc.), and sustainability.

- Prototyping and testing: Rapid iteration using tools like fluid dynamic simulations and mesh performance assessments.

We understand the importance of process control — particularly in applications with strict compliance requirements. From managing cooling cycles for thin-walled parts to maintaining alignment during welding or overmoulding, our systems ensure the uniformity and reliability of every unit.

A Strategic Manufacturing Partner

Our global footprint ensures we can deliver consistent, scalable production close to end markets, enhancing resilience of your supply chain and shortening lead times. Our commitment to quality is backed by international standards and sector-specific certifications.

For our customers, this translates to more than just product delivery. We help develop cost-effective manufacturing footprints, reduce energy consumption, optimise logistics, and explore recyclable or reusable materials where possible. Whether producing OEM parts, replacements, or consumables, our flexible setup supports ongoing innovation and sustainable growth.

Shaping the Future of Filtration Injection Moulding

As demand for filtration components grows and evolves, Rosti is ready to meet the sector’s technical and commercial requirements. Our full-service model, from initial concept to scalable production, ensures our customers gain a competitive edge, while delivering high-quality, high-performance components built for the future.

Would you like to learn more about how Rosti can help with your with Filtration manufacturing?