Comprising 8000m2 production and warehousing space, the Rosti UK site is based in Stamford Bridge, York. Providing plastic injection moulding solutions for the consumer goods, filtration, electrical, brewing and packaging markets, the site has a strong team of experts and a commitment to precision and performance.

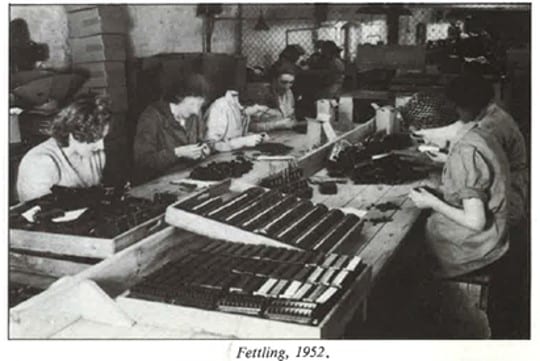

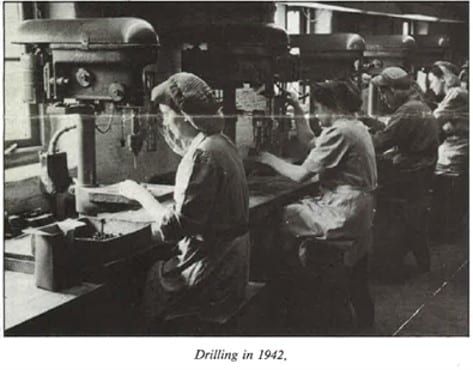

With a manufacturing heritage dating back to 1934, the company originally began as Derwent Plastics and the company began by producing components for radios and aircraft during World War 2.

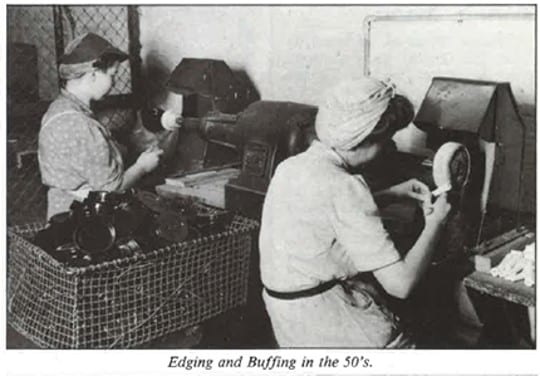

The first Thermoplastic injection moulding machine was installed in 1957 and the company went on to make various acquisitions throughout the 1970’s which resulted in several factory expansions.

Most recently, in 2017, Rosti UK split from Rosti Automotive, allowing us to better focus on the demands of the industry.

With a highly experienced team, our commitment to looking after our employees speaks for itself; with the average length of service standing at thirteen years, with six employees who have been with the company for over 30 years!

This varied experience means that the team have a great deal of knowledge that can be used to ensure our customer receives the best possible experience.

Producing more than 550 million beer can widgets annually, we have the ability to deliver high volume, automated production across our multiple production lines.

Our capabilities include injection and multi-shot moulding, laser etching, printing, welding and assembly, all carried out with the highest level of expertise.

The Rosti UK team take away all of the hassle with our end-to-end focus; managing the entire process including, NPI, tooling, production, material sourcing, storage and supply chain.

You are not just purchasing a moulded part or product from us, we collaborate with you and your team to ensure your exact requirements are met leading to long-term business partnerships.

It is Stamford Bridge’s mission to be the UK’s leading “technical” plastics and contract manufacturing business, creating a sustainable business that sits at the heart of this ambition.

In our effort to create an environmentally friendly site, 100% of our plastic is recycled and reused alongside our commitment towards Operation Clean Sweep. We have also invested in energy-efficient machinery and tooling, over 80% of our IMMs are high-efficiency electric machines.

We also have vast experience in the transfer of production back to the UK from overseas.

Offering cost-savings, efficiency and hassle-free completion of work, our experienced team can work with you to relocate your production with minimal disruption.

As part of a global group, the Rosti UK site is supported by a dedicated Production Transfer team. With over 100 years’ experience in the plastics industry, we have specific specialist knowledge in key areas and we can support you, the customer, throughout all aspects of the production transfer process.

From assisting in the physical transfer process, from the packaging of tools to the full transit and customs process, to investigating and securing local sourcing for materials.

Visit Our UK Site

If you would like to find out more about the Rosti UK site, we would be happy to arrange a tour – this could be in person or virtual.

Please contact [email protected] to find out more.