Rosti has a deep knowledge and experience in using an array of materials that comply with stringent sector and international regulatory and compliance standards.

Tag: Quality Systems & Assurance

Advancements in Producing Production Quality Plastic Prototypes

Advancements in production quality prototypes have evolved significantly in recent years.

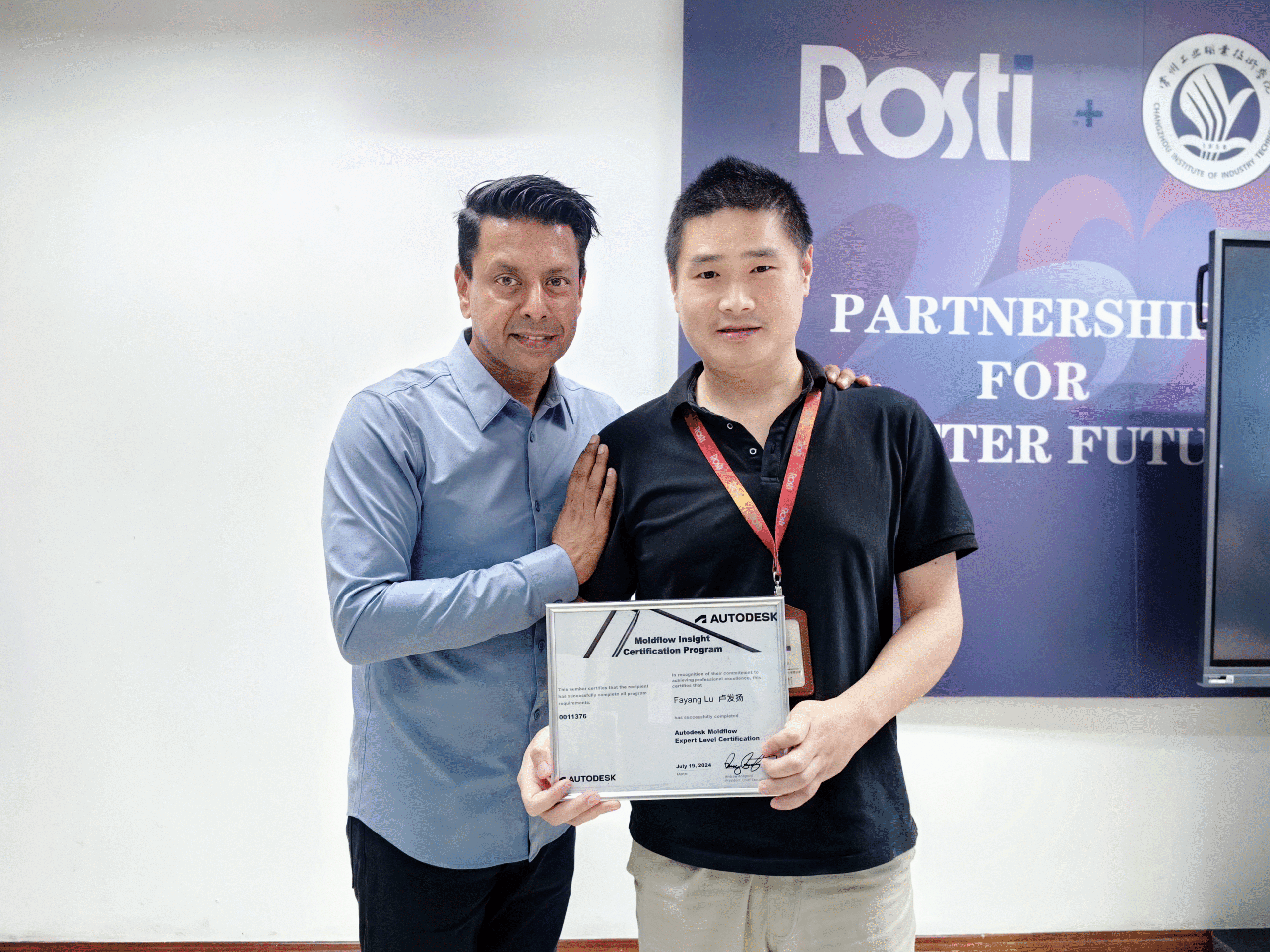

Devin Lu awarded Autodesk Moldflow Expert Certification

We are proud to announce that one of our employees Devin Lu, the Design Analysis Supervisor has successfully achieved the prestigious Moldflow Expert Level Certification, one of the 50 persons in China achieved this honor.

Celebrating World Quality Day at Rosti Poland

On World Quality Day, Rosti Poland were proud to highlight our commitment to quality excellence in everything that we do. This year, our team have engaged in a number of activities that not only celebrate quality but also underline its central role in our daily work.

Benefits of Dimensional Testing in Plastic Injection Moulding

A coordinate measuring machine (CMM) is a device that measures the physical geometrical characteristics of an object, and in our manufacturing application – plastic parts. The device is often used in manufacturing processes to qualify or test a part or against the design intent.

Preparing for Injection Moulding Resin Selection

Manufacturers use a wide variety of plastics to mold parts incorporated into products and have increasingly begun to replace other materials like bronze, stainless steel, aluminum, and ceramics. Some of the most popular reasons for using or switching to plastic include longer overall lifespan of the part, reduced wear on other components of a product, faster production line speeds, corrosion resistance and weight reduction. In addition, companies report an average 25-50 percent cost savings when parts are converted to plastic which oftentimes exhibit superior performance attributes.

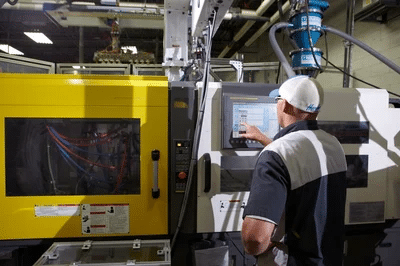

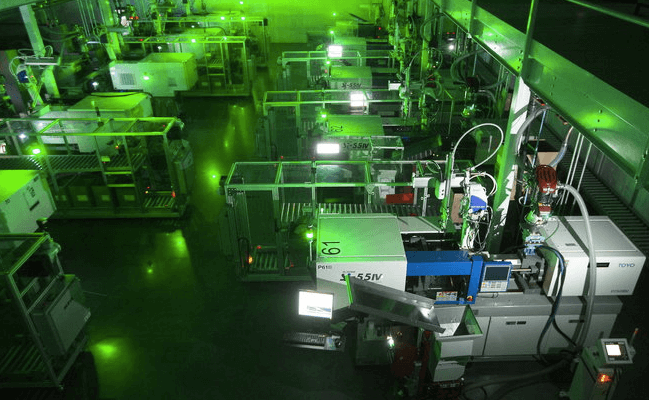

Advantages of Scientific Moulding Practices

Scientific molding practices are essential to achieving outcomes that deliver faster cycles, higher volumes, and a more efficient injection molding process. Implementing sound scientific principles can help with determining optimal molding conditions. Equipment and software that help monitor real-time production processes guide the scientific molding stages and provide a critical advantage. In addition, quality control issues can be avoided by having automated containment control and traceability for specific applications. From collecting data to machine maintenance, process development to resin characteristics, and much more – scientific molding helps identify efficiencies which result in greater value and better parts for customers.

Plastic Residence Time: Calculation and Process

From the specific plastic you are using, your mold, temperature, material density, and the machine itself and its individual parts, there are a number of variables that can make or break the injection molding process. One thing is certain: Processing too long or too short outside of the recommended plastic residence time can cause significant quality issues. Worse yet, not all resulting problems are immediately visible – inconsistency in melt quality, color variation, or weakened parts.

PCI Recognized with 2019 MAPP Innovation Award

Future success for many injection molders is dependant on the company’s ability to find efficiencies and innovative ways to improve business processes. Even small improvements can add up to big increases in productivity. Each year, the Manufacturers Association for Plastics Processors (MAPP) celebrates the innovative practices of a select handful of companies that touch on all areas of plastics manufacturing.

Rosti Malaysia awarded project to produce 15 minute COVID-19 Test for a Global Molecular Diagnostics company

Following the ISO13485 accreditation, Rosti Malaysia has partnered with a Global Molecular Diagnostics company to manufacture a COVID-19 test within 15 minutes.