Rosti Turkey successfully supported a global cosmetic brand to achieve their sustainability objectives by converting the packaging material to Polypropylene, as well as realising the benefits of Injection Mould Labelling (IML).

Having worked closely with the customer to understand their sustainability targets, Rosti Turkey were well positioned to support them in reducing the weight of the packaging by 7.6 grams per unit, eliminating secondary energy-intensive production processes. This further reduced the environmental impact of the product and realised a 22% cost saving.

Sustainable Injection Moulding

Rosti Turkey converted to Polypropylene from a crystal jar which has enabled our customer to save operational time and money whilst producing a more environmentally friendly product.

Previously, our customer used a crystal version of a jar which required a secondary heat treatment post-production to apply labelling.

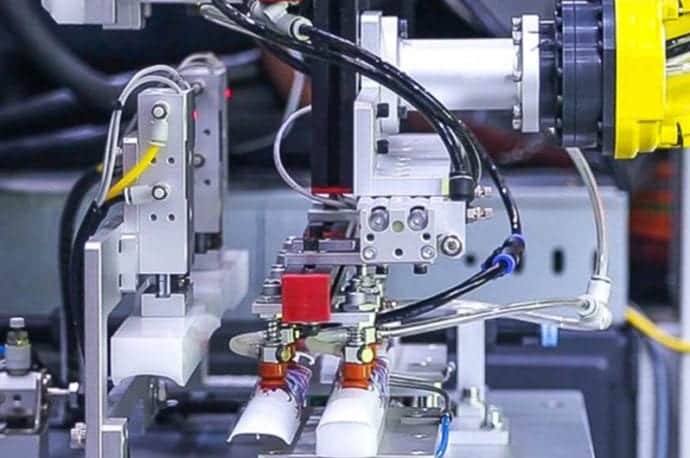

Converting to Polypropylene and In-Mould Labelling, there is now no need for secondary processing. As a result, the energy and time required have been removed from the production process.

Collaboration with Tooling Partner

As a result of transitioning to a new material, we worked closely with our long-term tooling partners to design and test new tooling to ensure it met the desired quality standards.

Our suppliers supported us to observe and develop the tooling and process throughout the manufacturing phase.

This collaborative approach was vital as we were converting to a new material and injection moulding process along with adjustments to the product.

Through developing our collaborative working relationship with our client,we have been able to reduce the carbon footprint of the product and manufacturing process by 12% which has also resulted in a 22% cost saving.