Rosti Turkey successfully supported a global cosmetic brand to achieve their sustainability objectives by converting the packaging material to Polypropylene, as well as realising the benefits of In-Mould Labelling (IML).

Tag: Material Selection

Rosti Group Global Partnership Model – benefits of Customer Collaboration

In the fast-paced landscape of the global plastic injection moulding industry, the importance of collaboration and knowledge-sharing across Rosti Group sites has never been more important than in the current global economy.

Rosti: Bringing Excellent Services for Sustainable Growth of the Automotive Industry

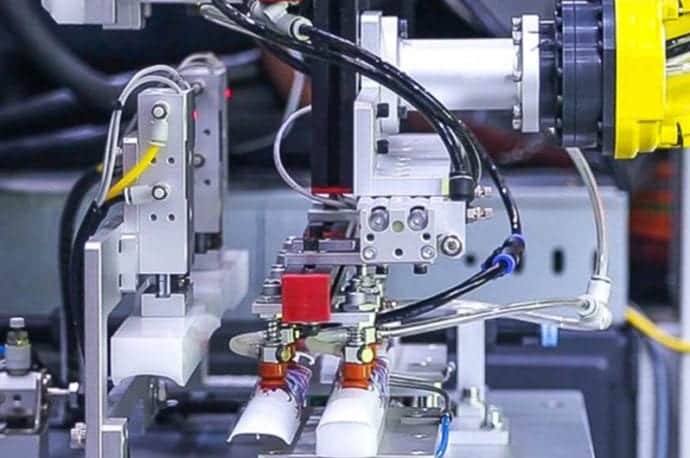

Plastics play an important role in automotive manufacturing. With the gradual popularization of energy conservation and emission reduction in automobiles, the lightweighting trend of replacing metal with plastic in automotive parts has become one of the most effective measures to reduce automotive emissions and improve combustion efficiency. In this aspect, injection moulding technology can also realise the integrated manufacturing of automotive parts, thereby improving the production efficiency in the automotive sector.

4 Reasons to Consider Metal to Plastic Conversion

Since the introduction of engineering-grade resins and plastic materials in the 1950s, many parts previously fabricated from metal have been replaced by injection molded parts. On average, companies report an overall cost savings of 25-50% by converting to plastic parts, yet some manufacturers have resisted making the change.

Key Qualities of High-Heat and Exotic Resins

Resin materials used in plastic injection molding have evolved significantly in recent years as advancements to combining plastics with fillers and reinforcement materials has become more common in many industrial applications to improve part performance and strength. In the past, plastics were not known to be highly heat resistant materials. It is becoming more known that there are now many high performance resins that can be put to use at temperatures up to 572 degrees Fahrenheit – depending on the part / product’s environmental factors and exposure to chemicals. High heat and exotic resins are particularly good metal replacement options because they provide incredible benefits in the areas of weight savings, chemical resistance, and sliding friction characteristics. Additionally, these great attributes can be maintained at high permanent operating temperatures.

Preparing for Injection Moulding Resin Selection

Manufacturers use a wide variety of plastics to mold parts incorporated into products and have increasingly begun to replace other materials like bronze, stainless steel, aluminum, and ceramics. Some of the most popular reasons for using or switching to plastic include longer overall lifespan of the part, reduced wear on other components of a product, faster production line speeds, corrosion resistance and weight reduction. In addition, companies report an average 25-50 percent cost savings when parts are converted to plastic which oftentimes exhibit superior performance attributes.

Design Tips for Injection Molding with High-Heat or Exotic Resins

Throughout the injection molding process, there are several factors that affect efficiencies and viability of a plastic part. Before production begins, there are important design elements to consider – particularly when a part requires the use of a high heat or exotic resins.

Rosti Sweden Awarded ISCC Plus Certification

Our plastic injection moulding facility in Gislaved, Sweden has recently been awarded ISCC Plus Certification, allowing us to handle and process recyclable and renewable materials suitable for food packaging applications.

Mateusz Surmacz shares insight into Medical Solutions growth

Mateusz Surmacz discusses the key areas of growth in the global medical solutions sector and how Rosti’s Clean Room capabilities support customers plastic injection moulding requirements.

Metal to Plastic Conversion Guide

This guide will help you understand the metal to plastic conversion process, its benefits, and how to partner with your injection molder to collaborate on all design for manufacturability elements.