Injection Moulding Complete Guide to Scientific Moulding

It’s not hard to understand how computing and innovation have positively impacted industries of all types over the past 35 plus years. The injection molding industry is no exception. Plastic injection molding nowadays is largely based on a scientific approach.

Scientific molding is a process whereby the fill, pack and hold stages are treated separately to minimize fluctuations while improving overall product consistency. Separating the stages is also known as decoupled injection molding. Molders who utilize scientific injection molding equipment, software, and practices can, according to scientific molding educator John Bozzelli, “reduce cycle times, increase machine efficiency, and ultimately make more money.”

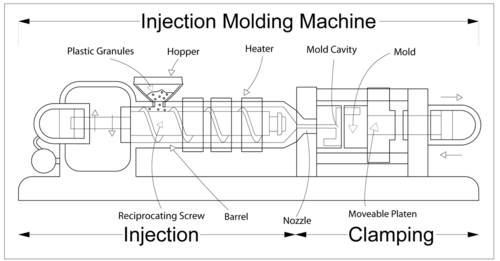

In the traditional method of injection molding, the mold is filled with a single shot under a constant pressure to pack the cavity. In scientific molding, the cavity is filled to around 90-97-percent at a certain velocity. In the next phase, the machine switches from speed control to pressure control, where the cavity is filled or “packed out” to complete the process.

The scientific method allows for greater shot-to-shot consistency and improved control over the specifications of the part. Conversely, large variations in part dimensions are often the case cycle-to-cycle with the traditional method of injection molding.

A scientific injection molding approach is most essential in the production of complex parts and components where even the smallest variation in molding variables can have a remarkable impact on the process or finished product. That said, the goal of scientific injection molding incorporates two key strategies:

- Develop a process that produces repeatable results with minimal variation

- Optimize dimensional or mechanical characteristics of a molded part

Another aspect of the traditional molding process has to do with machine-based control. It was believed there were 20 or more machine-based settings that could affect various problems with the molded product (dimensions, voids, warp, and other quality issues). The research sought to find parallels between problems with the parts with the settings of the machine.

Over the course of many years, when it was found machine settings had little or no correlation to part quality, research shifted from the traditional, machine-control method to a science-based approach. The “plastics point of view” became the revolutionary angle of modern research based on the laws of science instead of the settings of injection machines. Donald C. Paulson pioneered this scientific approach, having developed a plastics research laboratory at General Motors Institute in the mid-to-late 1960s.

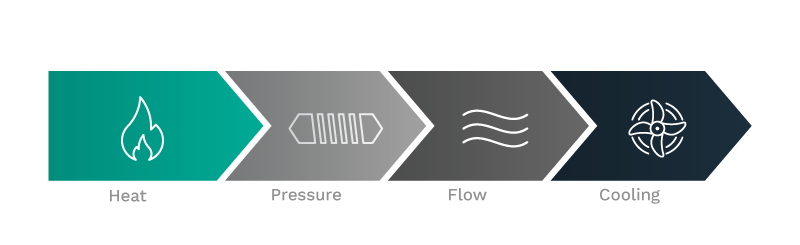

Mr. Paulson focused on the four injection molding plastic processing stages best known to control the properties of the molded part: heat, pressure, flow, and cooling. Each of these, Paulson hypothesized, “Would be governed by the laws of physics. First, the Laws of Heat Transfer; second, the Poiseuille fluid flow law; and third, the Equation of State for Plastic.”

Measuring and recording the machine and plastic variations for each of the four cycles over the course of four years led Paulson and his team of researchers to make a couple of industry-changing conclusions:

- Physical laws other materials follow also apply to plastic processing

- The four plastic variables determine the characteristics and properties of molded parts

The scientific approach to molding doesn’t change the molder’s need to understand machine setup or how the controls of a machine are used to impact plastic output and part quality. However, it does help the molder make better decisions on what the control settings and cycle times should be, along with solving part issues if and when they occur.

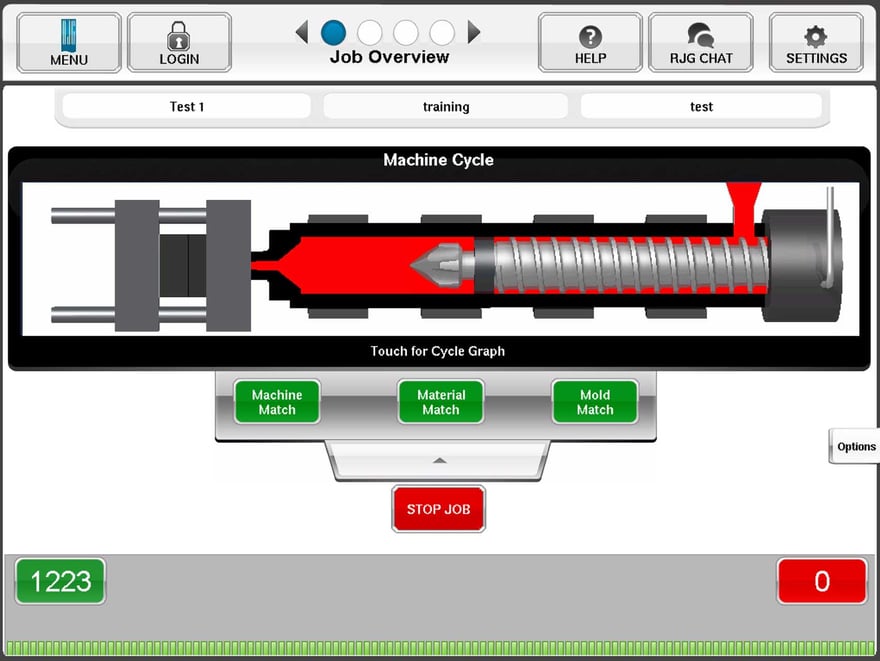

Scientific molding, at its core, focuses on decoupling the essential steps in the molding process. This decoupling ensures precision, accuracy, and control over each phase of the injection molding cycle. With advancements in technology, particularly the introduction of the RJG eDart® system, molders can now achieve higher levels of control and consistency.

Using equipment and software measurement tools, like the RJG eDart system, each cycle’s variables within the mold are continuously evaluated. This real-time monitoring is guided by the immutable physical laws governing plastics. These laws, concerning heat, pressure, flow, and cooling, are meticulously controlled under the supervision of specialty-trained engineers, ensuring that every component meets the highest standards.

- Initial Shot: The cavity is filled to approximately 98% of its capacity, with velocity being the key control parameter.

- Fill and Pack: The cavity is further filled, reaching its full capacity. The material is then compressed or “packed out” within the cavity, maintaining constant pressure. With RJG’s eDart systems, machine control is based on the plastic pressure inside the mold. This shift towards plastic pressure control, rather than solely relying on machine parameters, offers a more robust process window.

- Cool and Stabilize: As the molded part cools, it stabilizes. Only after reaching the desired stability is the part ejected, readying the machine for the next metered shot.

This decoupled approach, further enhanced by technologies like RJG’s eDart, provides molders improved control over part dimensions. More importantly, it ensures consistent quality from one cycle to the next, commonly referred to as shot-to-shot consistency in the industry. With such advanced process controls, Rosti can guarantee remarkably consistent product quality to its customers.

It’s not hard to imagine a world without scientific molding principles: product variations caused by wide fluctuations in temperature, pressure and viscosity, increased cycle times, decreased machine efficiency, higher costs, more rejects, and lower quality parts for customers.

As stated in our post on the advantages of scientific molding, “Scientific molding practices are essential to achieving outcomes that deliver faster cycles, higher volume, and a more efficient injection molding process.” In addition, “quality control issues can be avoided by having automated containment control and traceability for specific applications.”

Quote Style

“Scientific molding practices are essential to achieving outcomes that deliver faster cycles, higher volume, and a more efficient injection molding process.”

The technology behind scientific molding affords manufacturers the ability to operate more efficiently while creating the opportunity for a global competitive advantage. It also provides OEMs and customers higher-quality parts and fewer rejects at lower costs.

The principles and technologies involved with scientific molding solve the problem of how to get injection molding machines to make good parts each and every time.

The potential of scientific molding truly unfolds when paired with the latest advancements in injection molding technology. While it is a practice rooted in the laws of physics, its efficacy greatly hinges upon technological innovations, particularly in the realms of engineering, equipment, and software.

A prime example of this synergy is Rosti’s embrace of the RJG eDart system of advanced process control. This system, which focuses on controlling and monitoring the plastic pressure inside the mold, has been pivotal in transforming how injection molders approach their process. It’s not just about the machine setup or generic quality control anymore; it’s about utilizing cutting-edge technology to ensure the highest quality while also achieving cost savings.

From the initial machine setup to the intricate details of quality control and everything in between, technology, like the RJG eDart system, underscores the importance of continuous innovation. Such advancements have made it possible for molders to not only meet but exceed the exacting demands of their customers. In this context, technology isn’t just an enabler; it’s a game-changer for the overall success of the injection molding process. Let’s dive into this further below.

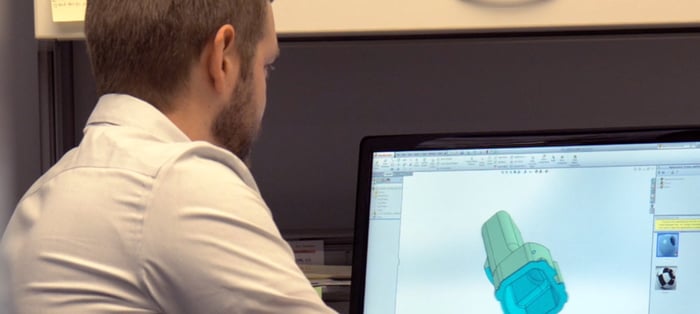

Scientific molding principles follow a data-driven approach. And data makes it possible to improve and see repeatable results. For example, Rosti utilizes mold flow simulation software by SOLIDWORKS®. As an up-front design validation tool for plastic injection molders, it provides predictive insight into plastic component design. Some key benefits of using the SOLIDWORKS software technology include:

- A shorter product development cycle and a reduced overall time to market through predictive insight into the component design in the early stages.

- Greater insight into plastic part geometry that would otherwise be too difficult or expensive to predict.

- The ability to identify potential problem areas upfront relating to sink marks, weld lines, short shots, along with other part defects and blemishes.

In short, SOLIDWORKS helps injection manufacturers get the part design right the very first time. In doing so, they’re able to eliminate costly mold rework, improve part quality, and reduce time to market.

While renowned for its consulting and training services – offering flagship courses like decoupled molding, high-performance molding, and Master Molder 1 & II certification – RJG’s eDart system has proved revolutionary in the molding process at Rosti.

Rosti’s adoption of the RJG eDart process control system has been transformative. Designed to empower molders with critical information, the eDart system is adept at reducing scrap, ensuring process stability, and delivering repeatable, superior-quality outputs.

Rosti’s ambitions have always been to maintain high press utilization rates. Such aspirations demanded an agile fleet of presses and an unwavering commitment to the principles of scientific molding. The eDart system, with its advanced in-mold pressure sensors, enhanced Rosti’s molding operations, providing unprecedented control and flexibility.

The journey began in September of 2009 when Rosti, facing unique challenges, integrated the eDart system into two of our presses. This integration proved so beneficial that a rapid expansion of the technology followed. By 2010, Rosti committed to a two-year initiative to ensure every press was empowered with the eDart system. This pursuit of excellence ensured that our commitment to closed-loop process control was not just a strategy but a defining element of our culture.

One of the pivotal outcomes, as Kurt Behrendt, Rosti’s director of engineering, pointed out, was the “transformational change in managing part consistency across various material lots.” This was achieved by the eDart system’s proficiency in monitoring and mitigating in-mold plastic pressure fluctuations. The outcome? An unparalleled consistency in the products Rosti molded.

Key advantages of integrating RJG’s eDart system into our scientific molding process include:

- Historical data recording for every molding shot, facilitating unparalleled insights.

- Real-time production monitoring, ensuring timely interventions when required.

- Significant boosts in quality assurance, leading to more consistent, top-tier parts.

- Drastic reductions in scrap and processing time, driving operational efficiencies.

In the realm of scientific molding, the amalgamation of mold flow simulation software, process control systems, and technologies like eDart forms the backbone of a robust automation strategy. Our deep dive into automation support follows next.

We’ve talked about the science of molding in terms of the laws of physics, steps in the process and the role technology plays in the areas of design, engineering, and process control. But scientific molding doesn’t end there. Not by a long shot. It also involves and benefits from automation and a highly-skilled workforce.

In this section, we’ll discuss the impact of automation on scientific molding and in the next, the importance of specialty-trained engineers and technicians.

The invention and deployment of automated tools and robotics have positively impacted virtually every industry. And the injection molding industry is no different. Make no mistake, the degree to which a plastic injection molder can automate its operations, the greater it will be able to grow its business and gain a globally competitive advantage.

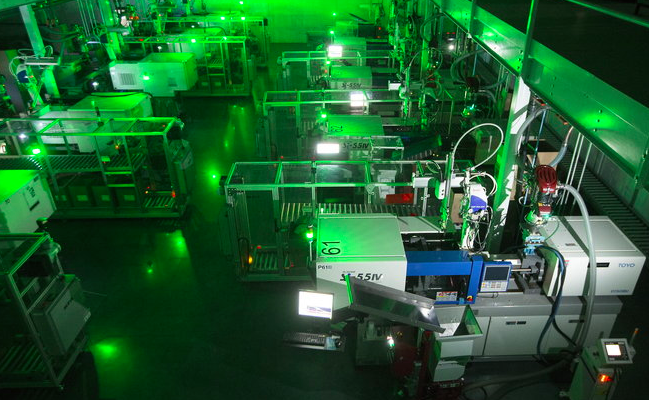

The ultimate mark of a scientific molding operation is a fully-automatic production facility, like the one Rosti pioneered beginning in 2011 at its Bunsen Drive facility. A fully-automatic facility is at times, also called a “lights out” facility. The manufacturing process at Rosti’s Bunsen Drive facility is so unique that the company was awarded U.S. Patent No. 8,827,674 B1 for the process: A specialized injection molding factory system and associated facility comprising machines on the first floor with the resin supply placed on a mezzanine level.

Four years ago, we published how a lights-out manufacturing facility has transformed injection molding. In it we described the lights-out process as follows:

“Lights-out manufacturing describes the process in which factories and production facilities are equipped with innovative and automated machinery to conduct tasks that would normally need a human [to be] present. Essentially, the production facility can run “lights-out” – or without substantial assistance from human labor, lights, heat, and other costly factors for a business. Lights-out manufacturing processes also allow companies to keep facilities running 24 hours a day, 7 days a week without the need of multiple workforce shifts.”

In this article, we also noted that “Not only has it allowed businesses to improve in the areas of cost and turn-around time, it has also allowed plastic part producers to lower the likelihood of defects and increase the overall quality of products created.” We noted a number of ways in which a lights-out facility has transformed injection molding, namely:

- U.S. manufacturers are able to gain a globally competitive advantage.

- Large orders can be completed quickly without the higher costs of adding more shifts.

- Quality control, delivery, and cost containment requirements are able to be reached.

- It requires a highly-trained and dedicated workforce to manage and maintain state-of-the-art automation equipment and processes.

Yes, scientific molding includes the technologies of mold fill simulation software, RJG eDart process control, state-of-the-art material handling systems, part conveyance systems, robotics, and a fully-automated, lights-out facility.

Quote Style

“Lights-out manufacturing describes the process in which factories and production facilities are equipped with innovative and automated machinery to conduct tasks that would normally need a human [to be] present.”

Even so, these ever-evolving technologies and lights-out methodology do not allow a business to run completely hands-free. In fact, without knowledgeable and highly-trained personnel, all of this simply wouldn’t be possible.

Rosti’s mix of experienced veterans and highly motivated young professionals are vital to its automation-focused and growth-oriented global business model. Up next, we’ll delve into the important role specialty-trained engineers and technicians play in scientific molding.

While understanding the intricacies of physics and technology isn’t mandatory for recognizing the transformative impact of scientific molding on the injection molding process, it’s undeniably essential to have specialized engineers and technicians at the helm. Their expertise ensures that science-backed injection molding systems are operated with precision and efficiency.

Rosti’s Comprehensive Approach to Molding Education and Training

Rosti places a premium on molding expertise. The company’s strategic hiring and training reflect an unwavering commitment to fostering excellence, including:

- Internship Pipeline: Each summer, Rosti welcomes between two to four interns. This proactive approach ensures a steady stream of potential talent, preparing for anticipated staffing needs.

- Targeted Recruitment: Rosti specifically hires engineers from educational institutions where students are exposed to both theoretical and hands-on scientific molding training. This ensures that the new hires are well-versed with the nuances of the industry from day one.

- Continuous In-plant Training: Partnering with industry experts like RJG, Rosti’s staff receive regular training on advanced concepts like decoupled II and III molding principles, pressure sensor specifications, the interpretation of eDart system outputs, and much more.

- Four-level Curriculum: To further solidify its commitment to excellence, Rosti has devised a comprehensive four-stage curriculum. This program is meticulously designed to elevate a beginner in molding to a level where they’re primed to undertake an RJG Master Molder course. The blend of on-site training and invaluable mentoring from in-house Master Molders paves the way for Rosti to cultivate its next generation of team members.

Decoupled II Molding:

This process involves filling the mold up to a specified position. Following this, the packing and holding phases are combined, where the second-stage pressure is employed to fully pack out the mold. This continues until the gate is sealed.

Decoupled III Molding:

In this method, the mold is initially filled to a specific position. A secondary filling phase or machine packing is then used to pack the mold up to a predetermined cavity pressure. Once achieved, the process is maintained, holding until the gate seal is established.

RJG’s eDart process control system is tailored to support decoupled molding processes. It aids molders in monitoring critical data, controlling variables in real-time, and ensuring consistency shot-to-shot. By integrating technologies like in-mold pressure sensors, the eDart system provides insights and controls necessary for the precise, step-by-step procedures of decoupled molding.

Rosti engineers are intimately involved throughout the entire scientific molding process. It begins early in the design specification phase with engineers working to design both the part to be molded along with the tool that will be used in the process. From there the engineer is able to specify how to incorporate pressure sensors in all of the new molds.

Once the sensors are in place, the tool is ready for testing under the direction and observation of engineers. Testing is conducted to identify any variables and the parameters required for consistent and optimal production.

With feedback from Rosti’s senior process technicians, our engineers approve the selection of decoupled II or decoupled III processes for each mold and confirm this process template for PPAP (Production Part Approval Process) and ongoing production. Once production is ramped up, engineers will continue to monitor readings and outputs to maintain and optimize the process for the best possible outcomes.

Design for manufacturing is a top consideration for reducing costs in scientific molding. The first company to commercialize design for manufacture and assembly (DFMA), Boothroyd Dewhurst, Inc., found that 80% of the cost of a new product is directly related to design.

According to John Gilligan, President of Boothroyd Dewhurst, Inc., “The use of DFMA to help choose the right structures, materials, processes, and labor has become critical given that companies get few second chances in today’s global markets.”

Therefore, the best time for a tool-maker / injection molder to get involved in the design process is early in the development cycle. Doing so will help to best understand customer objectives and avoid unexpected surprises.

In Rosti’s comprehensive guide to design for manufacturing in plastic injection molding, we’ve laid out a four-part approach to design optimization. They are as follows:

Design for Manufacturing

Design for Manufacturing (DFM) describes the process of designing or engineering a product to reduce its manufacturing costs, allowing potential problems to be fixed in the design phase, which is the least expensive place to address them.

Design for Functionality

Throughout the plastic part design process, it is imperative to keep focus on the functional requirements of the part. Experienced design engineers should make recommendations about modifications that will help ensure the part meets its functional requirements including what elements the part will be exposed to, chemical or corrosive materials the part will need to withstand, functional cosmetic attributes, and more.

Design for Assembly

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind with the ultimate goal of reducing assembly time and costs. The reduction of the number of parts in an assembly is usually where the major cost benefits of DFA occurs.

Design for Sustainability

Design for sustainability focuses on designing parts with print measurement intent in mind – sustaining tolerances with proper measurement on an ongoing basis.

According to Kip Doyle, author of an article on the Top 10 Reasons Why Molders Fail at Scientific Molding, many molders can’t get past a “machine-focused” approach and mold from the plastic’s “point of view.” He cites that many articles have been written on the four primary plastic variables (plastic temperature, plastic flow, plastic pressure, and plastic cooling rate and time), and a scientific molder must understand this approach and the process optimized from the perspective of the plastic.

Aligning with your injection molding partner to choose the best resin early in the design for manufacturability process, is crucial to a part’s production success. A good place to start is to have a general understanding of the two main types of resins – amorphous and semi-crystalline.

Polymers are made up of structures that are defined in terms of crystallinity – or how the molecules of the polymer are packed together.

Crystalline structures are, in most cases, very ordered, which gives the material strength and rigidity. Amorphous polymers are the opposite. Sometimes the distinction between the two is not clear cut. With most polymers, there is a mix of both crystalline and amorphous structures. How the polymer is processed determines the exact proportion of each.

In our post on Preparing for Injection Molding Resin Selection, we break down the differences in polymers further.

When considering the intended end use for your injection molded part, understanding these key characteristics is essential to selecting the best resin.

Part Appearance and Geometry

A part’s overall appearance and geometry have a significant impact on the molding capability and the type of resin that should be used. Part design, including size, shape, and wall thickness, can make a part prone to defects, while features like snaps, undercuts, bosses, ribs, and more can complicate the molding process.

It’s critical that injection molders use the latest technology to run simulations to optimize mold design specifications and resin choice before a project is finalized for production – this is where SolidWorks Premium plastics flow simulation provides predictive insight in the early stages.

Part Strength and Flexibility

Material selection also plays a critical role in the strength and flexibility of your molded part. Addressing specific needs early in the design process can help you avoid costly changes later. Balancing characteristics like stiffness, durability, toughness, and others are key in achieving optimal part functionality.

Using Additives

When material performance cannot be achieved with available resins, custom blends of materials can be created to boost the properties of multiple resins. Reinforcing materials with additives can build strength into parts and add stiffness that may reduce warping and shrink. Additives like glass or carbon fibers can be used to enhance part performance and improve flow, ejection, and dispersion.

High Heat Materials

We mentioned the important role of design in the injection molding process, and this is of particular concern when high-temperature materials are used to heighten a part’s strength, stability, and other features that are imperative to its unique application. Conventional molding techniques are not always effective with high-temperature and exotic resins.

Some characteristics of high heat and exotic resins are unique and may perform differently from one application to another. To realize both the design and material’s fullest benefits, experienced design engineers and injection molders have a number of factors to consider. In this post, outlined are a few basic and advanced tips that should be taken into account when designing parts for injection molding with the use of high-heat or exotic resins.

Plastic residence time is the time that plastic or resin is subjected to heat during fabrication.

Taking the time to calculate the specific plastic residence time for the relevant manufacturing process will improve your material performance and the overall final product.

Understanding the residence time of material in the first stage of the screw can help you understand the optimal time and temperature for your manufacturing needs.

What Does Plastic Residence Time Affect?

If plastic residence time is too long, it can affect part quality in several different ways:

- General weakness in parts produced

- Color variation

- Degradation not visible to the eye

- An overall compromised product

However, it can also impact machine performance, resulting in inconsistency in the melt quality and shot weight, as well as the melt temperature.

No matter how many shared formulas or calculations, plastic residence time should be calculated by each individual manufacturer in order to determine the ratio that works for their particular product.

Using scientific molding practices, Rosti uses recorded data to assess quality control and make any needed tweaks to tooling, thus improving overall part quality and avoiding the negative effects of poorly calculated plastic residence time.

Learn more about the importance of calculating plastic residence time here.

Plastic variables require understanding the nature of the material to be molded and its preferred molding conditions. When a material’s key characteristics, behavior, and response to processing is understood, scientific molders can optimize the molding process to produce the most consistent part possible.

The creation of tools for prototype and production components represents one of the most time-consuming and costly phases in the development of new products. To reduce the manufacturing lead-times and cost, prototyping and manufacturing processes have been rapidly developed through the evolution of scientific molding practices.

Scientific molding involves using data to develop a process that produces repeatable results with little to no variation. Through resin expertise and testing, dimensional and mechanical characteristics of a molded part can be optimized. Often achieved through the use of mold fill simulation and process control systems, predictive insight, process validation and complete process documentation are vital to producing demanding parts.

Part Optimization

Design engineers should lean on past learnings and expertise in optimizing part design for unique applications. Scientific molding elements associated with part design may incorporate using the latest software and technology, including computer-aided engineering, mold flow, and prototype development that will validate the part’s end-use.

Design considerations may include:

- Radius, draft angle, sink marks, wall thickness, etc.

- Gate location

- Weld line locations

- Environmental / end-use factors

- Part aesthetics

Injection molders should understand how to avoid designing a part, building the tooling, and beginning the molding process only to find out that the design does not work in production. Prototype tooling is an excellent method to validate and optimize critical mold and scientific molding variables.

Tool Optimization

Scientific molding practices can also be used to optimize tool design or to optimize poorly designed tools. It is essential for injection molds to be evaluated for their performance in the production of consistent, defect-free parts. Engineers should examine every aspect of a mold’s mechanical functionality using the appropriate material settings.

Testing can then be applied to check for any imbalances among cavities. When this analysis is complete, a gate seal study can be performed to gather data on where the gates seal fully at what points in the mold cavities. Recording findings and making recommendations for adjustments in the process or tooling are essential to correcting potential defects.

Quality control is integral in refining and perfecting the scientific molding process. The ability to harness and analyze recorded data means that adjustments can be made proactively, enhancing the overall quality of the molded parts. Once these quality benchmarks are achieved, scientific molding principles significantly streamline the manufacturing flow. This heightened efficiency is so pronounced that there is a reduced need for operator intervention and machinery oversight.

Leading-edge molders are now adopting groundbreaking “lights-out manufacturing” strategies. In these setups, advanced automated equipment undertakes operations that traditionally required human intervention, exemplifying the potential of technology in modern manufacturing.

The continuous advancements in scientific molding empower manufacturers with technology-driven processes, fostering a robust competitive edge on a global scale.

Additionally, RJG offers molders the ability to monitor essential parameters in real-time. By providing insights into critical variables, it allows manufacturers to maintain consistent quality, reduce scrap, and stabilize their molding processes. This system also aids in monitoring in-mold plastic pressure variations, ensuring that products are consistent in quality across various production runs.

RJG’s in-mold pressure sensors offer an additional layer of monitoring and control. Measuring and managing the pressures within the mold is a critical factor in achieving consistent and high-quality parts.

Its ability to record historical processing data on every shot means that injection molders have a wealth of information at their disposal to analyze and improve their processes. This data-driven approach enables a proactive response to any quality inconsistencies, leading to more predictable and reliable outcomes.

The advancements in scientific molding practices have impacted the plastics industry at a high level. Not only has it allowed businesses to improve in the areas of cost and turn-around time, but it has also allowed plastic part producers to lower the likelihood of defects and increase the overall quality of products created. Other examples include:

Competitive Advantage

When designing and producing complex injection molded parts, there is a lot of advantage to having a partner that is implementing state-of-the-art processes but also easily accessible from a geographic standpoint. Many companies are realizing the benefits to having their manufacturing partners close. The ability to react quickly and make important changes on a tight timeline is an important factor that comes up often in selecting a manufacturer. When production facilities adopt advanced manufacturing processes, including lights out functions, it communicates to their partners that they are working and producing parts as efficiently as possible.

Quicker Turnaround with Lower Cost

When manufacturing processes are set up and monitored in a smart and data-driven way, companies see their production capacities increase and orders completed at a much faster rate. While not appropriate for every job, automated molding is best for jobs that run at medium and high volumes, about 2,000 hours per year or more.

Additionally, the capacity, speed, and labor efficiencies created by scientific molding practices can be passed on to the customer – ultimately lowering overall product costs. When managed appropriately, the process improves OEM production flexibility as well.

Highly Trained Workforce

When we talk about automation, lights out manufacturing, and other scientific molding offerings by an injection molder, much of the emphasis is placed on the positive attributes associated with reducing human labor. While the process can create a more streamlined approach to production and may enable fewer people to be involved, not all projects can be run by technology. State of the art technology and processes require a highly trained and dedicated workforce that can make smart decisions and maintain equipment.

Protection for Intellectual Property

When product manufacturers rely on innovation and speed to market to be competitive in their industry, offshoring various aspects of production can expose designs to patent infringement, counterfeiting and more. Working with a reputable and knowledgeable partner that keeps everything from design, development, and production under one roof, will ensure that the manufacturer protects and retains all intellectual property, as well as learnings that are acquired throughout the process.

You can save money by partnering with a molder who uses scientific molding processes to intelligently design molds and validate parts. When molds are smartly designed, less material is used, and defects are reduced – both contributing directly to reduced costs.

Additionally, working with an injection molder who can identify opportunities for improvement during a design for manufacturing analysis will result in significant savings. Identifying problems in the early stages such as radius, draft angle, wall thickness, gate location, and other moldable features will eliminate financial and cosmetic issues along the way. In fact, as much as 80-percent of manufacturing costs can be determined by design decisions.

Why Rosti For Your Next Scientific Molding Project?

Scientific molding is a systematic and comprehensive approach to creating the efficiencies, cost structure, and production capabilities required for a manufacturer to compete on a global scale.

Implementing scientific molding practices has equipped Rosti with the ability to provide both superior quality and cost savings to our customers. In using highly advanced technology and processes, we are able to more efficiently produce parts while lowering the frequency of quality checks needed to ensure good parts. Rosti’s highly-trained and knowledgeable team provides our customers with confidence that their products will be produced consistently from part one to part 2,000,000 and beyond.

Would you like to learn more about Rosti’s scientific molding practices? To hear about our approach, or to discuss your next project, contact us today!