The tendency for North American manufacturers of plastic parts to outsource tasks to South America or overseas is changing back toward reshoring – or that of keeping production processes in house and within the United States. After decades of offshoring for economic purposes, wages in emerging economies have started to rise substantially.

Additionally, the high transportation cost and complex supply chain of offshoring causes precision issues, product delays and disruptions that are no longer being overlooked and certainly factored into the overall product cost. In an effort to create cost, quality and time efficiencies for customers, many American manufacturers have made the movement toward “lights-out” technology.

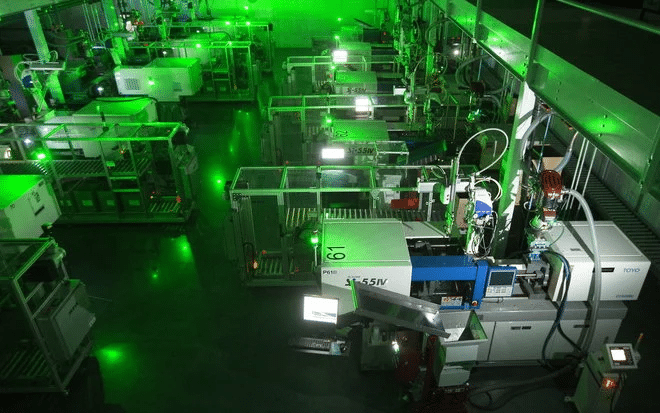

Lights-out manufacturing describes the process in which factories and production facilities are equipped with innovative and automated machinery to conduct tasks that would normally need a human present. Essentially, the production facility can run “lights-out” – or without substantial assistance from human labor, lights, heat and other costly factors for a business. Lights-out manufacturing processes also allow companies to keep facilities running 24 hours a day, 7 days a week without the need of multiple workforce shifts.

The advancements in automation and lights-out manufacturing processes have impacted the plastics industry at a high level. Not only has it allowed businesses to improve in the areas of cost and turn-around time, it has also allowed plastic part producers to lower the likelihood of defects and increase the overall quality of products created.

Here are 5 other ways lights-out manufacturing has transformed injection molding.

When designing and producing complex machined parts, there is a lot of advantage to having a partner that is easily accessible and only a short car or plane ride away. Many companies are realizing the benefits to having their manufacturing partners close. The ability to react quickly and make important changes on a tight timeline is an important factor that comes up often in selecting a manufacturer. When production facilities adopt advanced manufacturing processes including lights out functions, it communicates to their partners that they are working and producing parts as efficiently as possible.

When lights out manufacturing processes are setup and monitored in a smart way, companies see their production capacities increase and orders completed at a much faster rate. While not appropriate for every job, automated molding is best for jobs that run at medium and high volumes; about 2,000 hours per year or more.

The capacity, speed and labor efficiencies created by lights out manufacturing can be passed on to the customer – ultimately lowering overall product costs. When managed appropriately, the process improves OEM production flexibility as well.

When we talk about automation and lights out manufacturing, much of the emphasis is placed on the positive attributes associated with reducing human labor. While the process can create a more streamlined approach to production and may enable less people to be involved, not all projects can be run entirely lights out. State of the art technology and processes require a highly trained and dedicated workforce that can make smart decisions and maintain equipment.

5. It creates an added level of protection for intellectual property.

When product manufacturers rely on innovation and speed to market to be competitive in their industry, offshoring various aspects of production can expose designs to patent infringement, counterfeiting and more. Working with a reputable and knowledgeable partner that keeps everything from design, development and production under one roof, will ensure that the manufacturer protects and retains all intellectual property, as well as learnings that are acquired throughout the process.

Further advancements in automation and lights out manufacturing processes are happening everyday. One important consideration is that despite the ever-evolving technologies, lights-out methodology does not allow a business to run completely human-free. In fact, it requires a knowledgeable workforce that is adept at careful planning, programming, maintenance and more. The most accurate way to view the concept is that automation works with people, rather than replacing them. It’s an opportunity for a manufacturing business to optimize and create efficiencies in regard to the way its team works on a daily basis.

How has your production process benefited from automation or lights-out manufacturing?