In a rapidly evolving world, where technology and materials science merge seamlessly, injection molding of smart plastic components with embedded electronics is a game-changer.

These innovative components combine the durability of plastic with advanced electronics, creating products that are lightweight, functional, and versatile.

For businesses aiming to leverage this technology, partnering with an expert injection molding company is crucial. At Rosti Group, our Innovation Centres provide the tools, expertise, and infrastructure to transform ideas into functional, market-ready products.

Here, we’ll explore the benefits of working with a trusted injection molding partner and the future opportunities this technology presents.

Benefits of Working with a Plastic Injection Molding Partner

Expertise and Specialised Knowledge

At Rosti Group, our expertise lies in understanding the complexities of integrating electronics into plastic components. From advanced material selection to process optimisation, we ensure the highest standards choosing suitable plastics that have the appropriate tolerances. We do this through prototyping and validation processes to ensure a product is ready to go into production immediately.

Streamlined Manufacturing

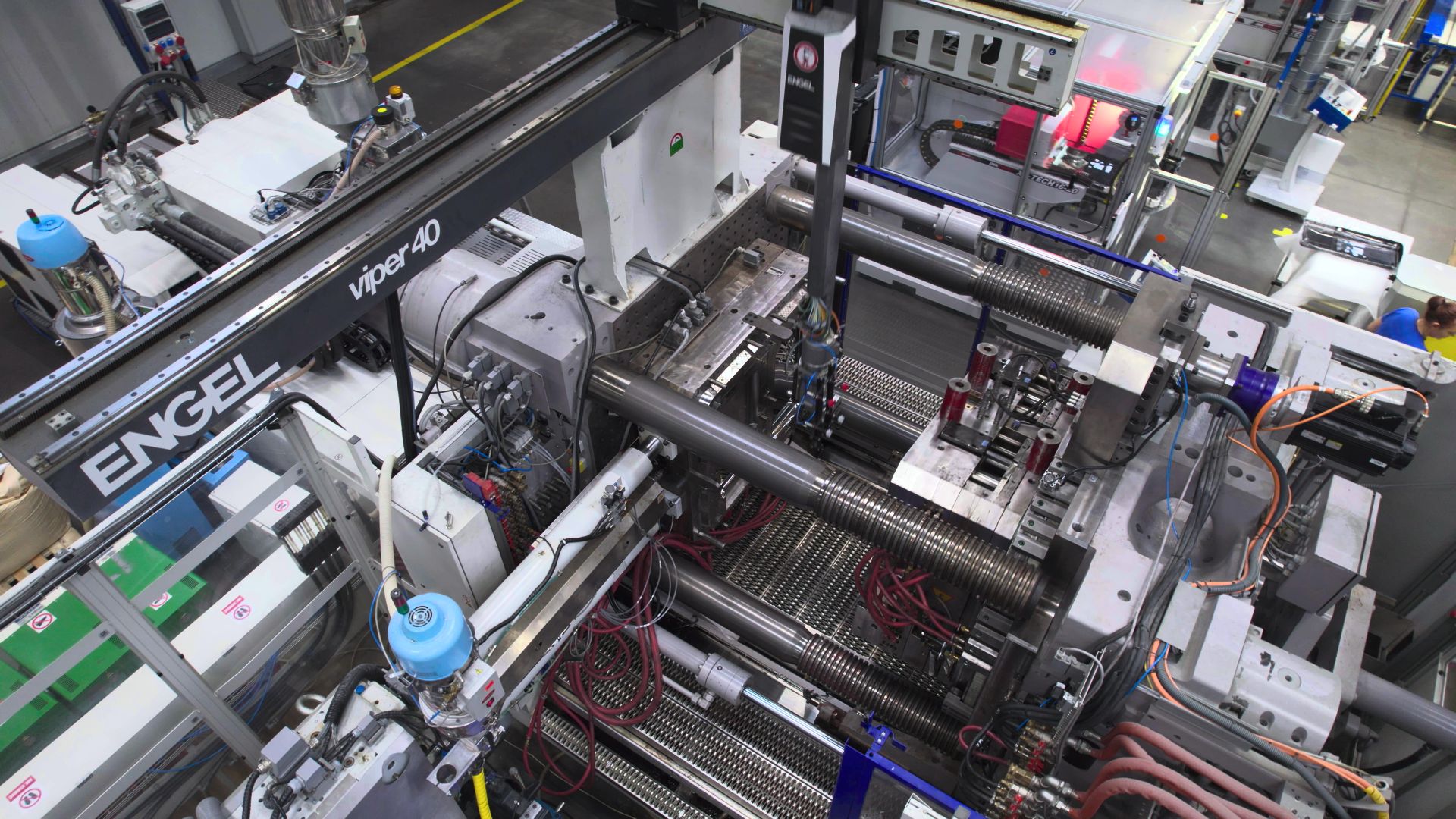

Our cutting-edge injection molding capabilities allow us to provide contract manufacturing by combining electronics and plastic into one production process.

As a contract manufacturer, our customers benefit from managing fewer suppliers, and realise cost efficiency opportunities as there are fewer steps to the production process and assembly.

This all culminates into a faster time-to-market as our customers benefit from our unrivalled expertise and experience, accelerating production and lead times.

Design and Innovation Support

Our Innovation Centres specialise in design for manufacturability (DfM), ensuring your components are optimised for mass production without compromising functionality.

Whether you’re creating touch-sensitive controls, embedded sensors, or aesthetic enhancements, we provide the tools and expertise needed for innovative designs.

Future Developments in Smart Components

As the demand for smart products grows, the potential for embedded electronics in injection molding continues to expand. We’re at the forefront of this evolution, leveraging our Innovation Centres to stay ahead of industry trends and help our customers design for the future.

The future lies in materials that enhance product performance while being eco-friendly. We’re constantly exploring recycled and bio-based plastics to support sustainability goals.

With advancements in microelectronics, embedding smaller, more powerful sensors and circuits into plastic components opens up new possibilities. Our expertise and range of molding capabilities allows us to support you to create compact products.

Our focus on sustainability goes beyond materials. We incorporate energy-efficient processes and innovations in waste reduction to support our customers’ environmental objectives.

The rise of smart devices has created demand for IoT-ready components. Rosti Group is uniquely positioned to support this market shift, integrating sensors and connectivity features into components that enable real-time data collection and advanced analytics.

Our Innovation Centres provide state-of-the-art facilities for product development and testing. This allows our customers to refine their designs with confidence, reducing risks and ensuring successful launches.

By partnering with Rosti Group, you gain access to a world of expertise, innovation, and reliability that positions your business for success in an increasingly competitive marketplace.