Multi-shot injection moulding is rapidly emerging as a key technology in the evolution of product design and sustainable manufacturing.

By allowing multiple materials or colours to be injected into a single mould in a single cycle, multi-shot moulding enables the creation of complex, multi-functional components without the need for secondary assembly.

As industries continue to push for higher performance and lower environmental impact, this innovative technique is proving to be a smart solution for both functional and sustainable product development.

Functional Benefits for the Customer

From a customer perspective, multi-shot moulding offers tangible advantages. One of the most significant is the reduction in assembly time and associated costs. With fewer separate parts required and minimal manual assembly, manufacturers can streamline production lines and reduce labour costs, while also minimising the potential for assembly errors.

Product quality, performance, and durability also benefit from the multi-shot approach. By combining materials directly into a part, manufacturers can enhance the functionality of components, improve user experience, and increase product lifespan.

Another key advantage is the aesthetic and design flexibility that multi-shot enables. The ability to combine different materials and colours within a single component opens up a world of creative possibilities for designers. It also supports the development of highly customised products tailored to specific user or brand requirements. With the support of dedicated design and development teams, we can help you to fully leverage the capabilities of multi-shot to deliver innovative, market-ready solutions.

Sustainability and Lightweighting

In today’s climate-conscious market, sustainability is no longer optional—it’s expected. Multi-shot moulding contributes to more sustainable manufacturing in several ways. First, by combining multiple functions into a single component, the process reduces the total number of parts required, as well as the number of production steps. This not only cuts down on material usage but also energy consumption and waste.

Multi-shot technology is also well suited to incorporating recycled or bio-based plastics as one of the component layers. This allows customers to reduce the reliance on virgin materials and support the circular economy, all without compromising on quality or performance.

Additionally, by reducing the need for fasteners or adhesives, multi-shot moulding can improve part recyclability and simplify disassembly at the end of the product’s life cycle. With growing consumer demand and increasingly strict regulatory requirements around environmental impact, those who invest in multi-shot technology are positioning themselves at the forefront of sustainable innovation.

Global Capabilities and Expertise

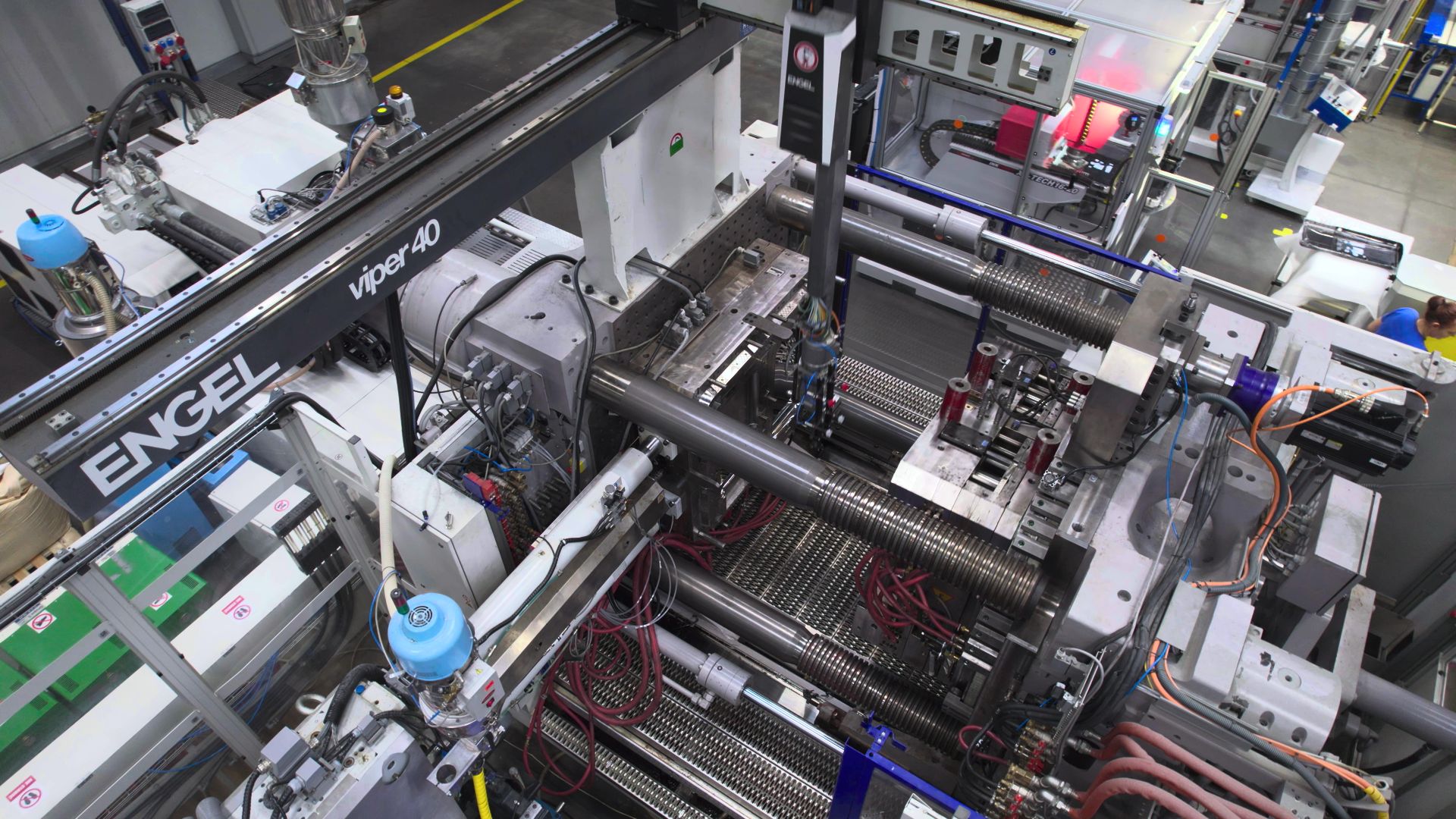

Our state-of-the-art facilities equipped with multi-k capabilities are complemented by Sustainability and Innovation Centres that help clients identify opportunities to enhance performance and reduce impact through multi-shot design.

Tooling design expertise plays a critical role in successful multi-shot projects. Combining deep technical knowledge with a process engineering approach ensures that tooling is optimised for efficiency, quality, and long-term value.